products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

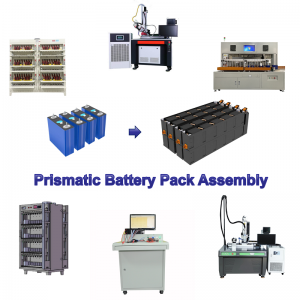

Prismatic Cell Battery Pack Semi-Automatic Assembly Production Line

Prismatic Cell Battery Pack Semi-Automatic Assembly Production Line

Prismatic Cell Battery Pack Semi-Automatic Assembly Production Line

-

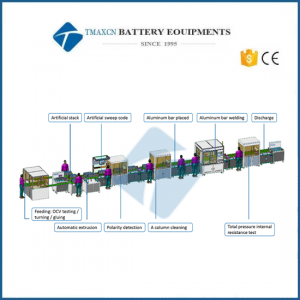

Prismatic Lithium Battery Pack Assembly Line Energy Storage PACK Semi-automatic Production Line

Prismatic Lithium Battery Pack Assembly Line Energy Storage PACK Semi-automatic Production Line

Prismatic Lithium Battery Pack Assembly Line Energy Storage PACK Semi-automatic Production Line

-

Energy Regenerative Type Battery Pack Aging Machine

Energy Regenerative Type Battery Pack Aging Machine

-

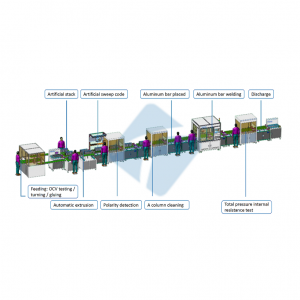

Customized Prismatic Cell Battery PACK Assembly Plant Semi-automatic Production Line

Customized Prismatic Cell Battery PACK Assembly Plant Semi-automatic Production Line

Customized Prismatic Cell Battery PACK Assembly Plant Semi-automatic Production Line

-

Semi-Automatic Production Line for Prismatic Cell Lithium Battery Pack

Semi-Automatic Production Line for Prismatic Cell Lithium Battery Pack

Semi-Automatic Production Line for Prismatic Cell Lithium Battery Pack

-

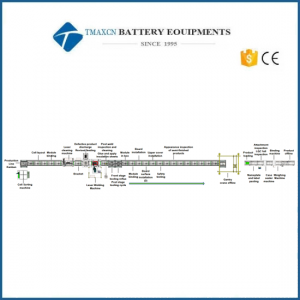

Automatic Wire Wedge Bonder for Cylindrical/Prismatic/Pouch Cell Battery Module Production Line

Automatic Wire Wedge Bonder for Cylindrical/Prismatic/Pouch Cell Battery Module Production Line

Automatic Wire Wedge Bonder for Cylindrical/ Prismatic/Pouch Cell Battery Module Production Line Ⅰ、Product description: After the battery module assembly process is completed, it is loaded by the automatic feeding system of the ultrasonic welding equipment & Al wire bonding machine, and then transferred to the ultrasonic welding area, and the welding head system performs ultrasonic welding according to the set welding parameters and positions. After the ultrasonic welding is completed the battery module is transferred to the designated position through the automatic feeding system, and the equipment operator takes the welded battery module away and sends it to a next production process processing. Ⅱ、Features: 1. Lead connection process, bonding aluminum wire can directly act as a fuse, and will automatically fuse in the event of a short circuit to ensure the safety of the battery pack. 2. The aluminum wire can match the stress requirements and tensile test requirements of the battery pack on the connection. 3. The use of aluminum wire bonding can achieve repeated welding, greatly improving the maintainability and recovery rate. 4. When using aluminum wire welding or aluminum strip welding, the temperature of the welding zone will not rise. Other traditional welding methods require heating to melt the metal. 5. Al wire bonding is a clean welding process. There are no flux residues or molten metal slag, avoiding reliability problems. 6. The battery pack welding quality inspection machine can accurately and quickly detect whether there is a problem with the connection between the battery and the busbar. 7. It is easy to detect if welding defects occur during aluminum wire welding, and it is easier to repair the defective positions without welding damage. Ⅲ、Scope of application: The fully automatic wire wedge bonder is suitable for the lithium-ion battery pack production for the lead connection between the battery cell and the busbar, and the sampling connection of battery cell status. It has applications in cylindrical battery packs, prismatic battery packs and pouch battery packs. Ⅳ、Specification: Product name Fully Automatic Wire Wedge Bonder Product model TMAX-UW-3000XK Input voltage 220V, 50/60Hz Power 3000 W Input gas source 0.5MPa X-axis travel 400MM (Customizable) Y-axis travel 800MM (Customizable) Z-axis travel 60MM (Customizable) Rotary-axis ±220°(Resolution: 0.08°) Transducer 60KHz (Customizable) Heavy wire welding head Rotatable, standard front cutter Welding pressure 50~1500 grams Maximum arc height 40 mm Wire feeding system Motor controlled wire feeder with optical encoder Minimum wire feeding length detection 2 mm wire feeding Aluminum wire diameter 125~500μm Aluminum wire coil size Outer diameter: 50~120mm Inner diameter: 10~11mm Width: 22~45mm Display 17-inch color display Visual system Image recognition system Communication method IO communication, network port communication Size(L*W*H) 1300*1300*1650mm Net weight 500KG

-

Auto Lithium Battery Pack Welding Quality Inspection Machine

Auto Lithium Battery Pack Welding Quality Inspection Machine

Auto Lithium Battery Pack Welding Quality Inspection Machine Ⅰ、Product description: The lithium-ion battery pack welding quality inspection machine is used to detect fake welding and missing welding of battery packs, and provides guarantee for the quality of battery pack welding. Ⅱ、Features: 1. Fully automatic detection, recording the data of each battery cell, greatly reducing the false detection and missed detection caused by manual detection. 2. Adopting modular design, it has good expansion flexibility and maintenance convenience. 3. The use of high-reliability hardware circuit design, high-frequency sampling technology and advanced digital control technology platform can ensure high-precision output and high stability, thereby ensuring test quality and data reliability. 4. Centralized control by the host computer, real-time monitoring of equipment operating status. 5. The server and MES system can be connected, which makes it easier to collect product test data. 6. The system uses self-developed test pins and high-reliability hardware circuit design to ensure stable and reliable test connections, thereby ensuring test quality and data accuracy, and providing effective guarantees and comprehensive data support for the reliability of battery modules. Ⅲ、Scope of application: This battery pack welding quality inspection machine is suitable for the rapid inspection of the welding reliability of lithium-ion battery packs of ultrasonic welding equipment & Al wire bonding machine, including 18650 battery module and 21700 battery module. Ⅳ、Specification: Brief introduction of the battery pack inspection equipment Product name Battery Pack Welding Quality Inspection Machine Product model TMAX-WQI-001TX Applicable modules 18650 battery module: 540*340mm 21700 battery module: 968*314*86mm 21700 battery module: 657*314*88mm Customizable Test speed ≤6~12min/side Gas nozzle distance The distance between the gas nozzle and the welding point: <10~18mm Blowing force 230~300g Detection accuracy Missed detection: 0% False detection: <0.5% Test pins life >300,000 times Current accuracy ±(0.05%FS+0.05%RD) Data recording time ≥100ms Software function Support cyclic working condition file import test function

-

Cylindrical Sodium Ion Battery Automatic Internal Circulation Heat Shrinking Machine

Cylindrical Sodium Ion Battery Automatic Internal Circulation Heat Shrinking Machine

Cylindrical Sodium Ion Battery Automatic Internal Circulation Heat Shrinking Machine Introduction PVC Heat Shrinking Machine using imported motor makes it more stable during pushing and sealing; Aspecially designed sealing knife makes sure solid sealing line, no cracking and anti-stick; Usage of imported electrical components reduces failure during the using process; It is an economical shrink packaging machine. The operation is simple. Just pressing the pusher button, the machine automatically seal then the products enter into shrink packaging machine. The machine mainly uses PE shrink film; The machine is widely used in drinks, daily chemical, building materials, food with paper tray or without paper tray etc. And it also can be used for electrical appliances, auto parts, furniture, flooring and other individual or group shrink wrap. Features: 1. Advanced design, stable and reliable performance, efficient power saving, good shrinkage effect, novel and beautiful structure,convenient operation and maintenance, etc. 2. The casing is thickened and the motor is enlarged. 3. Internal circulation of hot air, better energy and power saving effect. Specifications: Voltage 220V/380V Power 8KW Speed 0-15m/min Furnace channel size 1200*450*350mm(customizable) Machine size 1600*680*1070mm Max. loading weight 10kg Application material PVC POF PP Shrinking temperature 0-300C

-

100V 10A 20A Battery Pack Aging Machine

100V 10A 20A Battery Pack Aging Machine

-

100V 120A Charging and Discharging Battery Pack Aging Machine

100V 120A Charging and Discharging Battery Pack Aging Machine

-

Automatic Double Sides Spot Welding Machine with PC Control for EV Battery Pack Production

Automatic Double Sides Spot Welding Machine with PC Control for EV Battery Pack Production

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588