products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

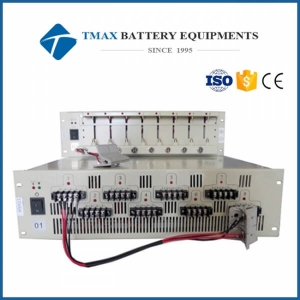

15V6A 8 Channel Universal Laptop Battery Pack Tester Equipment

15V6A 8 Channel Universal Laptop Battery Pack Tester Equipment

SPECIFICATIONS 1 TMAX-BTS-15V6A Battery tester equipment is an eight-channel battery analyzer to analyze polymer battery and cylindrical batteries from 12 mA to 6000 mA, up to 15V. 2 This battery test system provides most applications in battery testing fields such as electrode materials research, battery performance test, small-scale battery formation, capability grading, battery pack testing and etc. 3 This battery pack test system is mainly used for laptop battery pack performance testing.

-

15V6A Battery Pack Test System For Laptop Battery Pack Performance Testing

15V6A Battery Pack Test System For Laptop Battery Pack Performance Testing

15V6A Battery Pack Test System For Laptop Battery Pack Performance Testing 1 TMAX-BTS-15V6A Battery tester equipment is an eight-channel battery analyzer to analyze polymer battery and cylindrical batteries from 12 mA to 6000 mA, up to 15V. 2 This battery test system provides most applications in battery testing fields such as electrode materials research, battery performance test, small-scale battery formation, capability grading, battery pack testing and etc. 3 This battery pack test system is mainly used for laptop battery pack performance testing.

-

60V50A 2 Channel Electric Car Battery Pack Capacity Tester

60V50A 2 Channel Electric Car Battery Pack Capacity Tester

SPECIFICATIONS 1 TMAX-BTS-60V50A Battery test system is mainly used for Electric Car battery pack testing, it can test lithium battery pack voltage up to 60v with Max current 50A. 2 It can also test battery pack with protect board (PCB/PCM)

-

5V6A 256 Channel Li Ion Battery Capacity Tester For Pilot line

5V6A 256 Channel Li Ion Battery Capacity Tester For Pilot line

-

EV Battery Pack Module Automatic CNC Double Sides Spot Welding Machine for EV Battery Assembly Line

EV Battery Pack Module Automatic CNC Double Sides Spot Welding Machine for EV Battery Assembly Line

This machine is used for 18650 battery pack automatic spot welding, it can weld both side together with high speed and good effect. Features : 1. Support breakpoint start, support automatic start and manual start mode conversion. 2. It has a false spot welding and out of spot welding alarm function. 3. Programming is simple, and it supports any point programming and array programming. 999 groups can be saved programming files. 4. Welding needle replacement forecast reminder. 5. Own welding current monitoring system, real-time monitoring of welding current.

-

30V 10A 20A 18650 26650 32650 Battery Pack Charging&Discharging Testing Equipment& Aging Test Machine

30V 10A 20A 18650 26650 32650 Battery Pack Charging&Discharging Testing Equipment& Aging Test Machine

30V20A 4 Channel Battery Tester for Lithium Battery Charging and Discharging Cycle Testing

-

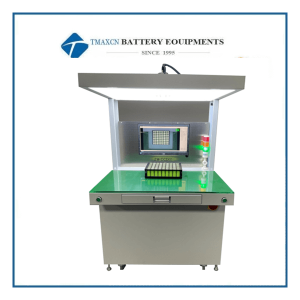

Automatic 13 Channel 18650 Cylindrical Battery Sorter/Selector for Battery Pack Assembly

Automatic 13 Channel 18650 Cylindrical Battery Sorter/Selector for Battery Pack Assembly

Automatic 13 Channel 18650 Cylindrical Battery Sorter/Selector for Battery Pack Assembly

-

Automatic Rotary Welding Head Single Side Spot Welding Machine for Battery Pack Manufacturing

Automatic Rotary Welding Head Single Side Spot Welding Machine for Battery Pack Manufacturing

High Accuracy Fully Automatic Rotary Single Side Spot Welding Machine

-

70V 5A Charging 10A Discharging Aging Cabinet Battery Pack Aging Testing Instrument

70V 5A Charging 10A Discharging Aging Cabinet Battery Pack Aging Testing Instrument

70V Charging 5A Discharging 10A Cabinet Battery Aging Testing Instrument

-

5-22 Channel Battery Sorter for 18650 26650 32650 21700 Cylindrical Cell for Battery Pack Assembly

5-22 Channel Battery Sorter for 18650 26650 32650 21700 Cylindrical Cell for Battery Pack Assembly

5-22 Channel Battery Sorter for 18650 26650 32650 21700 Cylindrical Cell for Battery Pack Assembly

-

Cylindrical Cell Battery Pack Semi-Auo Assembly Machine Line for 14500 18650 21700 26650 32650 Cylindrical Cell

Cylindrical Cell Battery Pack Semi-Auo Assembly Machine Line for 14500 18650 21700 26650 32650 Cylindrical Cell

Cylindrical Battery Pack Assembly Machine for All Kinds of Cylindrical Cell

-

Battery Pack Making Machine 2 in 1 for 18650/26650/32650 Lithium Battery Cells Sorting and Insulation Paper Sticking

Battery Pack Making Machine 2 in 1 for 18650/26650/32650 Lithium Battery Cells Sorting and Insulation Paper Sticking

Donut Label Machine Connecting with Cylindrical Battery Cell Sorting Machine for Battery Pack Assembly

-

100V 120A 18650 Battery Pack Comprehensive Tester Multi Functional Test Equipment

100V 120A 18650 Battery Pack Comprehensive Tester Multi Functional Test Equipment

100V 120A 18650 Battery Pack Comprehensive Tester

-

CCD Visual Inspection Equipment for Positive and Negative Battery Electrode Detection

CCD Visual Inspection Equipment for Positive and Negative Battery Electrode Detection

CCD Tester for Lithium Battery/CCD Positive and Negative Electrode Battery Pack Testing Machine

-

Automatic Internal Circulation Heat Shrinkable Film Packaging Machine for PVC POF PP

Automatic Internal Circulation Heat Shrinkable Film Packaging Machine for PVC POF PP

Automatic Internal Circulation Heat Shrinkable Film Packaging Machine for PVC POF PP Introduction PVC Heat Shrinking Machine using imported motor makes it more stable during pushing and sealing; Aspecially designed sealing knife makes sure solid sealing line, no cracking and anti-stick; Usage of imported electrical components reduces failure during the using process; It is an economical shrink packaging machine. The operation is simple. Just pressing the pusher button, the machine automatically seal then the products enter into shrink packaging machine. The machine mainly uses PE shrink film; The machine is widely used in drinks, daily chemical, building materials, food with paper tray or without paper tray etc. And it also can be used for electrical appliances, auto parts, furniture, flooring and other individual or group shrink wrap. Features: 1. Advanced design, stable and reliable performance, efficient power saving, good shrinkage effect, novel and beautiful structure,convenient operation and maintenance, etc. 2. The casing is thickened and the motor is enlarged. 3. Internal circulation of hot air, better energy and power saving effect. Specifications: Voltage 220V/380V Power 8KW Speed 0-15m/min Furnace channel size 1200*450*350mm(customizable) Machine size 1600*680*1070mm Max. loading weight 10kg Application material PVC POF PP Shrinking temperature 0-300C

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588