products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Double Side Automatic Spot Welding Machine for New Energy Vehicle

Double Side Automatic Spot Welding Machine for New Energy Vehicle

Double Side Battery Tab Spot Welding Machine

-

84V 5A Charging 10A Discharging Battery Pack Testing Cabinet

84V 5A Charging 10A Discharging Battery Pack Testing Cabinet

84V 5A Charging 10A Discharging Battery Pack Testing Cabinet 1.Introduction: TMAX-BCD-S84V aging cabinet is mainly used for charging and discharging cycle test of finished lithium battery. The test items include: battery charging protection voltage, discharge protection voltage, capacity, etc.; the equipment has four test steps of charging, discharging, shelving and cycling. By editing the corresponding steps, the battery can be tested according to the set process. 2.Specification: Technical Parameter Input power AC220V±10%/50Hz Voltage Measuring Range 36-84V Accuracy ±(0.2% of reading +0.2% of range) Current Charging Range 50-5000mA Charging Accuracy ±(0.2% of reading +0.2% of range) Discharge Range 50-10000mA Discharge Accuracy ±(0.2% of reading +0.2% of range) Charge Constant Voltage Cut-off Current Minimum 50mA Capacity Accuracy ±1% Power Discharge Power ≤840W Time Inspection Time Real-time Collection<2S Timing Range 0-999h/step Data Recording Interval ≥5S Middle Machine Version 1:1 series Number of Passages Per Cabinet 12 channels, six rows and two column Charge Charging Mode Constant Current and Constant Voltage Charging Cut-off condition Voltage, Current, Relative Time, Overcharge Protection Discharge Discharge mode Constant current discharge Cut-off condition Voltage, Relative Time and Over-discharge Protection Loop Cyclic measurement range 1-999 times Single cycle step number 100 Voltage and Current Detection Sampling Four-wire sampling Data Base Using SQL database to manage test data Upper computer communication mode Based on TCP/IP Protocol/Serial Port Data Output Mode EXCEL/TXT/Chart Communication Interface Mesh port Chassis dimensions 300x450x170mm Cabinet size 1600x600x1800mm Spatial Dimension of Discharge Battery 400x460x200mm 3.Range of Application: 4.Selection of battery pack charge and discharge aging machine:

-

100V 20A 40A Lithium Battery Pack Charging and Discharging Test Cabinet Ageing Machine

100V 20A 40A Lithium Battery Pack Charging and Discharging Test Cabinet Ageing Machine

-

100V 200A Finished Battery Pack Comprehensive Tester

100V 200A Finished Battery Pack Comprehensive Tester

-

Single Side 5000A/8000A Automatic Spot Welding Machine with Rotary Head with Host Computer Program for EV/ Electric Bike/Power Battery Making

Single Side 5000A/8000A Automatic Spot Welding Machine with Rotary Head with Host Computer Program for EV/ Electric Bike/Power Battery Making

-

13 Channel Cylindrical Battery Sorter with Computer System for All Types of Cylindrical Cell

13 Channel Cylindrical Battery Sorter with Computer System for All Types of Cylindrical Cell

-

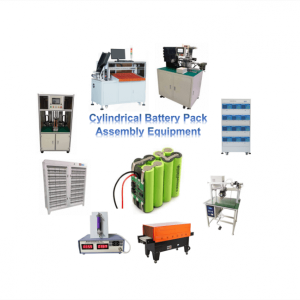

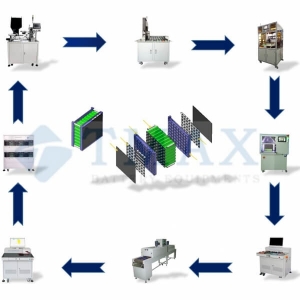

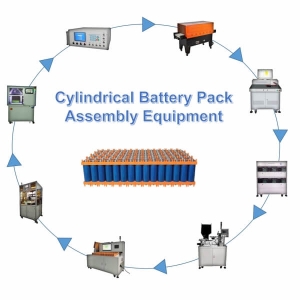

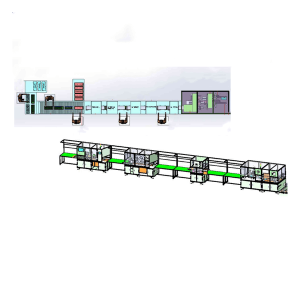

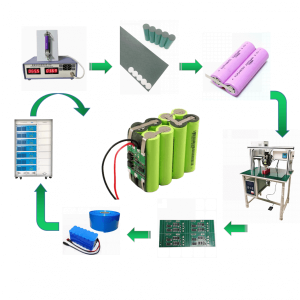

Battery Pack Assembly Line for LiFePo4 Lithium Cylindrical

Battery Pack Assembly Line for LiFePo4 Lithium Cylindrical

-

Lifepo4 Battery Pack Assembly Equipment Plant for E Bikes Battery and Electric Scooters Battery

Lifepo4 Battery Pack Assembly Equipment Plant for E Bikes Battery and Electric Scooters Battery

-

Battery Pack Assembly Plant for 18650 Cylindrical Cell

Battery Pack Assembly Plant for 18650 Cylindrical Cell

-

Cylindrical Battery Pack Assembly Machine Plant for Lithium Battery EV Bike/Solar Light Assembly Production

Cylindrical Battery Pack Assembly Machine Plant for Lithium Battery EV Bike/Solar Light Assembly Production

Cylindrical Battery Pack Assembly Machine for All Kinds of Cylindrical Cell

-

Lithium Battery Packing Equipment for Lifepo4/EV Bike/Power Battery Pack Manufacturing

Lithium Battery Packing Equipment for Lifepo4/EV Bike/Power Battery Pack Manufacturing

Lithium Battery Packing Equipment

-

18650 Cylindrical Cell Assembly Line of Lithium ion Battery Pack Module

18650 Cylindrical Cell Assembly Line of Lithium ion Battery Pack Module

18650 Cylindrical Cell Assembly Line of Lithium ion Battery Pack Module

-

Automatic Cylindrical Cell Pack Assembling Equipment Plant for LiFePO4 Cell/ E-Vehicles Cell/Electric Scooters Battery Pack

Automatic Cylindrical Cell Pack Assembling Equipment Plant for LiFePO4 Cell/ E-Vehicles Cell/Electric Scooters Battery Pack

Cylindrical Cell Pack Assembling Equipment for LiFePO4 Cells/ E-Vehicles Cells/Electric Scooters Battery Pack

-

Lithium Battery Nickel Strip Roll Nickel Plated Steel Strip for Battery Packs Spot Welding

Lithium Battery Nickel Strip Roll Nickel Plated Steel Strip for Battery Packs Spot Welding

Lithium Battery Nickel Strip Roll Nickel Plated Steel Strip for Battery Packs Spot Welding

-

Manual 18650 Lithium Battery Pack Assembly Line Project

Manual 18650 Lithium Battery Pack Assembly Line Project

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588