products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

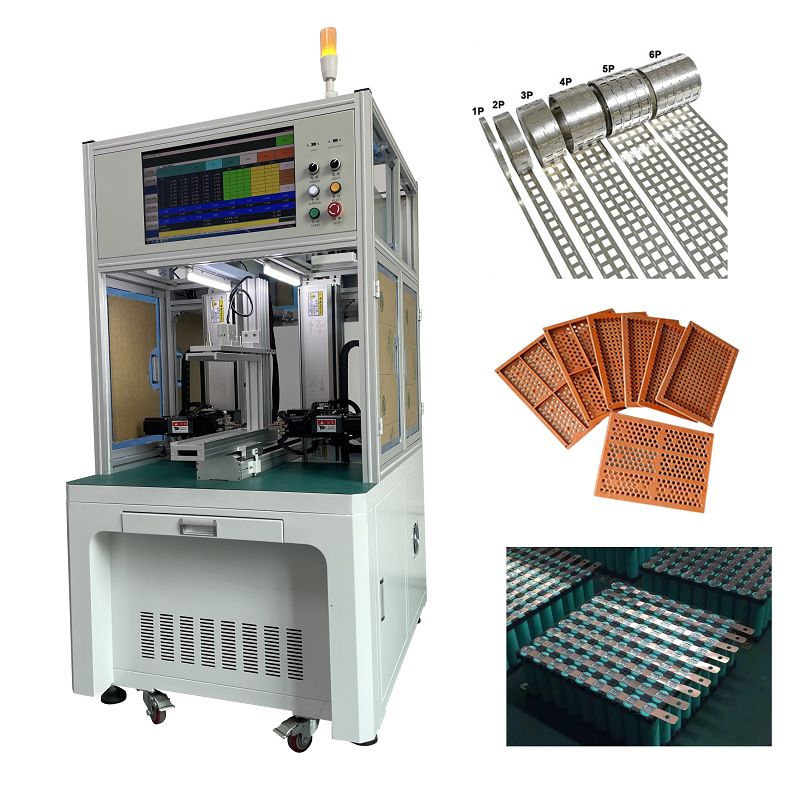

Automatic Double Sides Spot Welding Machine with PC Control for EV Battery Pack Production

Model Number:

TMAX-ZWRD300Type:

AutomaticInput Power:

2000WNet Weight:

200kgCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPlace of Origin:

ChinaUpdate:

OptionalShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

10000A Transistor Dual-Sided Automatic Welding Machine with PC for Cylindrical Battery PackNext:

10000A Transistor Single-Sided Spot Welder with PC Control System for Cylindrical Lithium Battery Pack

Automatic Double Sides Spot Welding Machine with PC Control for EV Battery Pack Production

Features

Spot welding machine has stable performance, can be used in various battery types and multiple battery pack processing, convenient and fast fixture replacement, beautiful appearance, all aluminum alloy body.

Performance Features

1. Touch screen display, more convenient operation and clearer display.

2. Three file programming modes, manual input, array, CAD drawing import, simple and fast response to various complex program editing.

3. The welding head has the function of air cooling or water cooling, which can effectively reduce the impact of spot welding needle temperature on welding quality. 4. It can store up to 99 groups of files, which is easy to use and does not need complicated process of line changing and machine adjusting.

5.The spot welding program of A side and B side of fixture can be switched.

Specification

Product |

Double Side Automatic Spot Welding Machine |

Number of storable filegroups |

99 |

Model |

TMAX-ZWRD200 |

Operate System |

PC |

Y-axis Travel |

500mm (can be customized) |

X-axis Travel |

400mm (can be customized) |

Driving mode |

Stepper motor / servo motor |

Repeated Positioning Accuracy |

±0.02mm |

Max Welding Speed |

0.35s/spot, 2800pcs/h |

Power |

2000W |

Max Motor Speed |

1000mm/s |

Weight |

200kg |

Max Battery Number |

X:26 Y:26 |

Maximum bearing weight of Y-axis |

50kg |

Rotation Function of Welding Head |

The welding head supports positive and negative rotation, and is suitable for spot welding of special-shaped batteries and anti-sticking needle function. |

Welding Material |

Pure nickel strip: 0.03-0.2mm Nickel-plated steel strip :0.03-0.3mm |

![]()

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588