products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

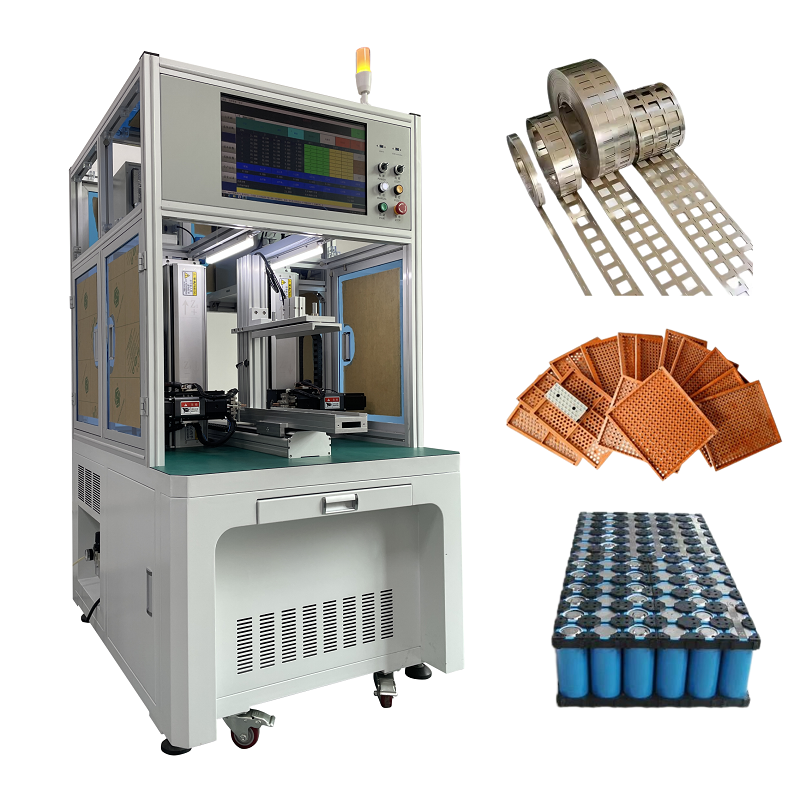

10000A Transistor Dual-Sided Automatic Welding Machine with PC for Cylindrical Battery Pack

Model Number:

TMAX-ZW-D300BType:

AutomaticInput Power:

2000WNet Weight:

350kgCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPlace of Origin:

ChinaUpdate:

OptionalShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

5000A/8000A Single-Sided Spot Welder for Cylindrical Power Battery(with PC control)Next:

Automatic Double Sides Spot Welding Machine with PC Control for EV Battery Pack Production

10000A Transistor Dual-Sided Automatic Welding Machine with PC for Cylindrical Battery Pack

Introduction

The dual-sided automatic welding machine is specifically designed for cylindrical lithium batteries, widely used in power batteries (such as electric vehicle batteries) and other cylindrical battery packs. This equipment ensures high-quality welding through efficient welding technology, making it an ideal choice for enhancing battery production efficiency.

Features

Automated Spot Welding: The highly automated spot welding process significantly improves production efficiency and reduces labor costs.

Data Upload Functionality: Welding data can be uploaded in real-time to the MES system, facilitating production monitoring and management, thereby increasing overall production transparency.

Dual-Sided Spot Welding: Capable of performing dual-sided welding simultaneously, it shortens the production cycle and accommodates various battery pack requirements, particularly suitable for power batteries and high-capacity batteries.

Flexible Customization: The Y-axis and Z-axis strokes can be customized according to customer needs, meeting different production environment requirements.

Machine Parameters

- Y-axis Stroke: 600mm (customizable)

- Z-axis Stroke: 400mm (double) (customizable)

- Maximum Spot Welding Speed: 0.35 seconds/spot (approximately 5500 18650 cells)

- Motor Drive Speed: 1000mm/S

- Maximum Cell Loading: Y-axis: 24 cells; Z-axis: 20 cells

- File Group Storage Capacity: 100 groups

- Operating System: Upper computer industrial control system

- Transmission Method: Precision lead screw and guide rail from Taiwan

- Drive Method: Stepper servo motor

- Repeat Positioning Accuracy: ±0.02mm

- Dimensions: L: 1150mm, W: 1000mm, H: 1780mm

- Total Power: 4000W

- Total Weight: 350KG

- Maximum Y-axis Load Capacity: 50KG

- Input Power Supply: Three-phase 380V 50HZ

- Air Source: 0.4-0.6Mpa

![]()

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588