products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Cylindrical Cell AA AAA 18650 Shrink Wrapping Machine With PLC Control

Cylindrical Cell AA AAA 18650 Shrink Wrapping Machine With PLC Control

-

Automatic Cylindrical Battery PVC Heat Shrink Wrapping Machine for Cylindrical Battery Making

Automatic Cylindrical Battery PVC Heat Shrink Wrapping Machine for Cylindrical Battery Making

Automatic Cylindrical Battery PVC Heat Shrink Wrapping Machine for Battery Pack Assembly

-

Automatic 18650 PVC Heat Shrink Wrapping Machine for Cylindrical Battery

Automatic 18650 PVC Heat Shrink Wrapping Machine for Cylindrical Battery

Automatic 18650 PVC Heat Shrink Wrapping Machine for Cylindrical Battery

-

Automatic 32650 PVC Heat Shrink Wrapping Machine For Cylindrical Battery

Automatic 32650 PVC Heat Shrink Wrapping Machine For Cylindrical Battery

Automatic 32650 PVC Heat Shrink Wrapping Machine For Cylindrical Battery FEATURE The cylinder battery laminating machine is a kind of automatic equipment which is used for laminating of cylinder battery, punching and placing insulating gasket and heat shrinkable standard. This equipment can pack about 3300 electric cores per hour, and the structure design is simple and generous, and the performance is stable. In the market, up to now, it is one of the most cost-effective integrated standard equipment Technological process The parameter setting is completed through the touch screen, and the following functions are automatically completed by PLC: manual loading of battery core→ feeding by motor + cylinder → battery delivery by chain → battery core correction + servo labeling → laminating surface pad → correction again → spinning feeding + tunnel furnace heat shrinking → the first turning of air cylinder → loading by belt running → the second turning of air cylinder (feeding groove of finished battery core) → feeding and discharging groove; equipment allocation Sound light alarm is set.Operation parameters can be set according to the actual requirements Structure 1) The structure of the equipment is compact and reasonable, the appearance is beautiful, and the occupied space is small. 2) The equipment is easy to operate, and workers can easily master it without professional training. 3) The equipment is controlled by PLC, which is responsible for battery feeding, labeling, laminating surface pad, heat shrinkable insulation skin, easy to learn, high efficiency, labor cost saving, and good product performance. 4) The equipment and materials are made of high-quality thick cold-rolled sheet metal and aluminum profile frame. 5) The equipment is equipped with universal casters, which makes it easy to move and handle the equipment. SPECIFICATION Power Supply AC 220V±10%/50Hz, Power:≤5KW Working air source 0.5~0.6Mpa Suitable for 32650 etc cylindrical cell Productivity ≥ 55PPM Qualified rate ≥ 98% Weight 600kg Size 2000(L)×900(W)×1700(H)mm

-

3-1 Tape Wrapping Machin for Polymer Battery/Power Battery/Mobile Cell

3-1 Tape Wrapping Machin for Polymer Battery/Power Battery/Mobile Cell

-

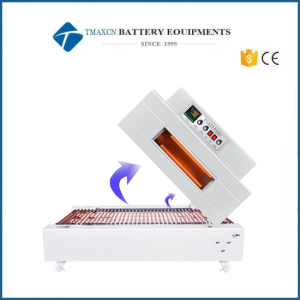

Semi Automatic PVC PP Film Heat Tunnel Shrink Packaging Packing Wrapping Machine

Semi Automatic PVC PP Film Heat Tunnel Shrink Packaging Packing Wrapping Machine

Semi Automatic PVC PP Film Heat Tunnel Shrink Packaging Packing Wrapping Machine Introduction: The far-infrared shrink packaging machine is the latest automatic continuous shrink packaging equipment in the market.The shrink temperature and motor drive speed are stable and controllable, the adjustment range is wide, and there are instrument displays. The original roller auto-transmission device can work continuously. Features: 1.Using far-infrared tube for heating, saving more than 15% 2.Advanced design, stable and reliable performance, efficient power saving, good shrinkage effect, novel and beautiful structure,convenient operation and maintenance, etc. Specification: Voltage 220V 50Hz Power 5.5KW Speed 0-10m/min Furnace channel size 800*400*200mm (customizable) Machine size 1100*600*670mm Max. loading weight 15kg Application material PVC POF PP Maximum scope of application Unlimited length Width 37cm Height 17cm Shrink Film Temperature / Time Comparison Table Film PVC PP POF Thickness 0.02-0.06mm 0.02-0.04mm 0.03-1.1mm Heating time 5-10S 6-12S 8-16S Shrinking temperature 110-130C 130-170C 130-170C Packaging Film Classification

-

Prismatic Cell Battery PVC Blue Film Covering Machine

Prismatic Cell Battery PVC Blue Film Covering Machine

1 This TMAX-PVM-5L Planetary vacuum mixer machine is a set of vacuum mixing, dispersion of efficient equipment, suitable for lithium electricity experiment process is anode paste mixing process, solder paste, silica gel, chemical industry, etc 2 This lab planetary mixer Mixing motor adopts transmission frequency adjustment, can choose different rotational speed and torque according to different process, different viscosity. 3 The vacuum planetary mixer is excellent for preparing LiCoO3, LiFePO4, Phosphors and ceramic slurry without gas bubble. And the processed material results in the better dispersion and uniformity.

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588