products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

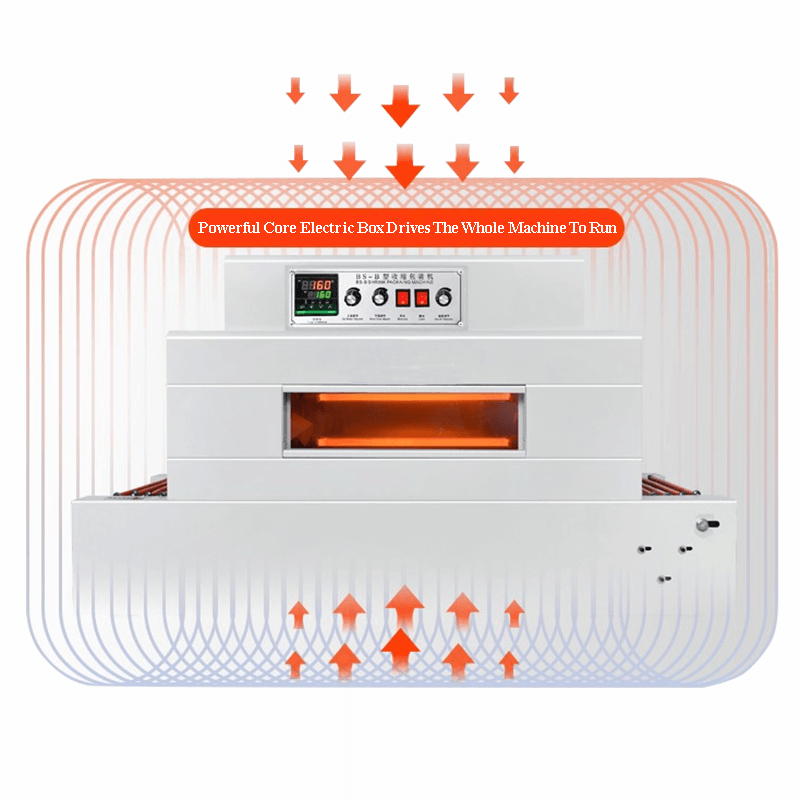

Semi Automatic PVC PP Film Heat Tunnel Shrink Packaging Packing Wrapping Machine

Model Number:

Tmax-CWT-BS-4020Input Power:

5.5KWCompliance:

CE Certified/NRTL CertifiedWarranty:

One years limited warranty with lifetime technical supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

7 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Li Battery Assembly Automation Line for Electric Tools /Solar Products / EV /Energy Storage BatteriesNext:

8000A Transistor Manual Spot Welder Lithium Battery Welder

Semi Automatic PVC PP Film Heat Tunnel Shrink Packaging Packing Wrapping Machine

Introduction:

The far-infrared shrink packaging machine is the latest automatic continuous shrink packaging equipment in the market.The shrink temperature and motor drive speed are stable and controllable, the adjustment range is wide, and there are instrument displays. The original roller auto-transmission device can work continuously.

Features:

1.Using far-infrared tube for heating, saving more than 15%

2.Advanced design, stable and reliable performance, efficient power saving, good shrinkage effect, novel and beautiful structure,convenient operation and maintenance, etc.

Specification:

Voltage |

220V 50Hz |

Power |

5.5KW |

Speed |

0-10m/min |

Furnace channel size |

800*400*200mm (customizable) |

Machine size |

1100*600*670mm |

Max. loading weight |

15kg |

Application material |

PVC POF PP |

Maximum scope of application |

Unlimited length Width 37cm Height 17cm |

Shrink Film Temperature / Time Comparison Table |

|||

Film |

PVC |

PP |

POF |

Thickness |

0.02-0.06mm |

0.02-0.04mm |

0.03-1.1mm |

Heating time |

5-10S |

6-12S |

8-16S |

Shrinking temperature |

110-130C |

130-170C |

130-170C |

Packaging Film Classification

![]()

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588