products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Lab Powder Compaction Density Measurement System Tester For Lithium Battery Cycling Performance Testing

Lab Powder Compaction Density Measurement System Tester For Lithium Battery Cycling Performance Testing

Lab Powder Compaction Density Measurement System Tester For Lithium Battery Cycling Performance Testing 1.Background The compaction density of the powder materials is not only related to its particle size and distribution, but also closely effect the capacity, internal resistance and the cycling performance of the produced lithium-ion batteries (LIBs). Theoretically speaking, the higher the compaction density, the higher the capacity of the LIB can be. Therefore, the compaction density is used as one of the key indicators to evaluating the energy density of materials. The compaction density is closely related to the intercalation and deintercalation of lithium ions during the cycling. Appropriate compaction density can effectively increase the capacity of the LIB reduce internal resistance, reduce polarization loss, and prolong the overall service life of the battery. On the one hand, the measurement of powder compaction density can be used as an effective index to monitor the differences between batches of powder materials, and on the other hand, it can be used as an effective means of R&D material evaluation and process optimization 2.Creative Solution The integrated design of the pressure application and thickness measurement modules can measure the compaction density under different quantitative pressures in real time; Fully automatic measurement software system, multi-parameter synchronous acquisition, intelligent and efficient testing process; Various testing modes such as single point, variable pressure, pressurization, and pressure relief can be optional, and the performance of the powder material can be evaluated in an all-round way; Equipped with machine inspection standard parts, preprocessing equipment and automatic demoulding equipment to ensure stable testing and improve overall efficiency 3.Measurement System Analysis (MSA) 4. Application Cases ① Effective evaluation of the compaction density of positive and negative electrode powders and conductive ② Monitor the long-term stability of the compaction density of the material; ③ Realize the effective evaluation of material stress-strain performance; ④ Realize the effective evaluation of material compression rebound performance; Application Case - Long-term Stability Evaluation of Nickel Cobalt Manganese Materials Parameters: 12MPa, 180MPa, hold pressure for 10s, test 3 groups every day, a total of 30 days of testing. Result analysis: The results of compaction density in 30 days are all less than ±3σ, and the long-term stability of the compaction density of this sample is good. Long-term stability of the compaction density of the sample can be monitored! Application Case - Lithium Iron Phosphate Material Evaluation Parameters: 10-200MPa, sampling points at an interval of 20MPa, holding pressure for 10s, a total of 5 groups of tests. Result analysis: The COV of the compaction density of 5 groups under each pressure is less than 0.5%, and the data fluctuation range is less than 0.05g/cm3, indicating that the the repeatability of this equipmentis good. It can evaluate the real-time change trend of the compaction density of the material with the increase of the pressure! Application Case-Lithium Cobalt Oxide Material Evaluation Parameters: 10-200MPa, sampling points at intervals of 20MPa, holding pressure for 10s, and tested 4 samples in total. Result analysis: The results show that the stress-strain curves of the four lithium cobalt oxide materials are different during the compression process, and the compression properties of the materials can be further evaluated in combination with the material particle size distribution. It can help R&D to evaluate the stress-strain performance of materials Application Case-Graphite and Carbon Material Evaluation Parameters: 10-200MPa, sampling points at intervals of 20MPa, hold pressure for 10s, release pressure to 3MPa, hold pressure for 10s, test 4 samples in total. Result analysis: The results show that the thickness rebound of graphite and carbon materials during the process of pressurization and decompression are different, and the rebound of graphite material is greater than that of hard carbon. It can help research and development to evaluate the compression rebound performance of materials! Parameters and installation requirements Model PCD1000 PCD2000 Max pressure 1000kg 5000kg Pressure measurement resolution/accuracy 0.1kg/±0.3%FS Thickness measurement range 0-8mm Thickness measurement resolution/accuracy 0.5um/±10um Maximum capacity that can be filled Φ13*8mm(can be customized) Power supply 200-240V/50-60Hz Voltage variation tolerance ±10% Power 450W 2100W Environment temperature 10-35C, 13mm*8mm(customizable) Environment humidity <80%RH(no condensation) Net weight 85kg 250kg Size W330*D402*H780mm W370*D565*H1200mm

-

Lab Lithium-ion Battery Powder Resistivity Measurement System & Compaction Density Measurement System

Lab Lithium-ion Battery Powder Resistivity Measurement System & Compaction Density Measurement System

Lab Lithium-ion Battery Powder Resistivity Measurement System & Compaction Density Measurement System The significance of powder resistance The rate performance of lithium-ion batteries is closely related to the battery resistance. The battery resistance includes ionic resistance and electronic resistance. The ionic resistance mainly refers to the resistance of lithium ions in the electrolyte in the electrode pores, the resistance of lithium ions through the SEI membrane, and the resistance of lithium ions and electrons. The charge transfer resistance of the active material/SEI film interface and the solid phase diffusion resistance of lithium ions inside the active material. The electronic resistance mainly refers to the resistance of the positive and negative active materials, the current collector resistance, the contact resistance between the active materials, and the contact resistance between the active material and the current collector. And the welding resistance of tabs. In the actual battery development and producti on process, the ionic resistance part needs to be evaluated at the finished battery end, and the electronic resistance part can be quickly evaluated at the material and pole piece end. Therefore, the accurate evaluation of the material and the electrode elect-ronic resistance is important for the battery. The resistance estimation is of great significance. Measurement system analyze Test condition: 5 samples, 3 operators, 3 times/pcs/operator %GRR accepted rule %GRR<10% Excellent 10%<%GRR〈30% Acceptable %GRR>30% Unacceptable ndc accepted rule ndc>10 Excellent 5<ndc < 1 Acceptable ndc < 5 Unacceptable ♦ Compact density : GRR-Excellent ♦ Powder Resistance : GRR-Excellent Applications Application cases 1.LCO material assessment (evaluation of electrical properties of modified powder(LCO)) Parameter: 10-200MPa, 5MPa steps, keep 15s Results: When the Compact density of the modified powder is greater than 3.87g/cm3 (applied pressure > 75MPa), the conductivity of the modified powder is greatly improved. The effectiveness of the modification can be evaluated. 2.NCM material assessment (relation of powder resistivity and electrode: NCM material) Results Analyze By adjusting the Ni content in the ternary material, the powder conductivity increases with the increase of Ni content. Compared with three kinds of ternary electrodes with different Ni content, the conductivity of the electrode increases with the increasing of Ni content; Powder resistivity and electrode have the same trend ! 3.NCMA material assessment (relation of powder resistivity and electrode: NCMA material) Results Analyze The conductivity trend of the Quaternary powder and electrode under three different modification conditions is NCMAT > NCMA-2 > NCMA-3 ; The conductivity of NCMA43 in powder state is much smaller than that of the former two samples, but there is a small difference in the electrode plate, which may be related to the addition of conductive in the electrode plate, which reduces the difference between the powder. Powder resistivity and electrode have the same trend ! 4.LFP material assessment (relation of powder resistivity and electrode: LFP material) Results Analyze Compared with the LFP powder and electrode sheet under four different modification conditions, the conductivity trend of LFP powder and electrode sheet is as follows LFP-1>LFP-2>LFP-3>LFP-4 Powder resistivity and electrode have the same trend! 5.Graphite material assessment (compact density: parallel test 5 times) Parameter: 20~200MPa, 20MPa steps, keep 30s, relief 3MPa steps, keep 10s Results Analyze The cov of five parallel samples is less than 0.1% in the whole pressure range, which indicates that the equipment has good repeatability. With the increase of pressure, the Compact density of graphite material increases gradually and tends to be flat. The rebound of powder thickness under pressure and pressure relief reaches the maximum value at 80MPa, which indicates that this condition is the maximum pressure that the powder can bear, and if it is too large, the material structure is likely to be damaged. 6.Carbon material assessment (compact density VS resistivity: parallel test 5 times) Parameter: relief mode: 10~200MPa, 10MPa steps, keep 10s Results: The cov of five parallel samples is less than 0.3% in the whole pressure range, which indicates that the equipment has good repeatability. With the increase of pressure, the Compact density of carbon material increases gradually, and the compaction range is 0.5-0.9 g / cm3 . ♦ Part of the data comes from the partners, and the copyright belongs to the relevant parties. It can not be reproduced or used without consent High accuracy pressure system : Driven by servo motor. High accuracy displacement sensor : Precisely measure the variation of thickness. Specific clamp for resistivity & compaction density test of powder samples: Simplify the process of the powder loading and cleaning. Multi-functions : One-stop data collection of key parameters of pressure, resistance, thickness, temperature and humidity with high reliability, to provide a complete traceability for each result. Automatic measurement: Providing flexible measurement modes for different kinds of samples, and all the process parameter setting are integrated into a simple software control interface, with one-button to start a measurement. PRCDMS Software: 1.Pressure can be set willfully within the extent of max pressure. 2.The resistivity under different pressure can be measured in succession with controllable rate and interval of pressure scan. 3.Different data analysis curves can be generated, including resistivity-pressure curve, resistivity-thickness curve, compaction density-pressure curve, and pressure-thickness curve. 4.Two resistance data collection modes: interval time mode or automatic steady state condition determine mode. 5.Data statistical analysis functions. 6.Automatic generation of reports with the value of resistivity (or conductivity) and Compaction density. Integrated design : Integration of control and measurement systems for pressure, resistivity and thickness control and measurement systems. Application fields Carbonaceous Powders : Active materials of Lithium Ion Batteries and various electronic components (capacitor and resistor; etc.), including graphite, activated carbon, coke, carbon black, carbon fiber; carbon nanoparticles, etc. Metal oxide or metal composite powders: Active materials of Lithium Ion Batteries, conductive pastes, conductive coatings and other functional films, including LCO, LMO, LFR NCM, LTO copper powder; ITO powder; etc. Parameter Resistance range 1uΩ-1200mΩ Resistance accuracy ±0.05% Resistivity range 10^(-6)Ω cm-10^9Ω cm Conductivity range 10^(-9)^S/cm-10^6 S/cm Pressure range 0-200 MPa Pressure accuracy ±0.30%F.S Thickness range 0-8 mm Thickness accuracy/resolution 0.5um/±5um Max filling capacity Φ16*8 mm Temperature and humidity range 20-90%RH, 0-50℃ Temperature and humidity accuracy ±5%RH, ±2℃ Installation requirement Voltage 220V Voltage change tolerance ±10% Power consumption 2100W Environment temperature 25±5℃ Environmental humidity Humidity at 40℃ <80%RH Environmental magnetic field Away from intense electromagnetic fields Net weight 165kg Dimension(W*D*H) 370*580*1100 mm

-

Lab Lithium Cell Powder Resistivity Measurement System & Compaction Density Measurement System For Cylindrical Cell R&D

Lab Lithium Cell Powder Resistivity Measurement System & Compaction Density Measurement System For Cylindrical Cell R&D

Lab Lithium Cell Powder Resistivity Measurement System & Compaction Density Measurement System For Cylindrical Cell R&D The significance of powder resistance The rate performance of lithium-ion batteries is closely related to the battery resistance. The battery resistance includes ionic resistance and electronic resistance. The ionic resistance mainly refers to the resistance of lithium ions in the electrolyte in the electrode pores, the resistance of lithium ions through the SEI membrane, and the resistance of lithium ions and electrons. The charge transfer resistance of the active material/SEI film interface and the solid phase diffusion resistance of lithium ions inside the active material. The electronic resistance mainly refers to the resistance of the positive and negative active materials, the current collector resistance, the contact resistance between the active materials, and the contact resistance between the active material and the current collector. And the welding resistance of tabs. In the actual battery development and producti on process, the ionic resistance part needs to be evaluated at the finished battery end, and the electronic resistance part can be quickly evaluated at the material and pole piece end. Therefore, the accurate evaluation of the material and the electrode elect-ronic resistance is important for the battery. The resistance estimation is of great significance. Measurement system analyze Test condition: 5 samples, 3 operators, 3 times/pcs/operator %GRR accepted rule %GRR<10% Excellent 10%<%GRR〈30% Acceptable %GRR>30% Unacceptable ndc accepted rule ndc>10 Excellent 5<ndc < 1 Acceptable ndc < 5 Unacceptable ♦ Compact density : GRR-Excellent ♦ Powder Resistance : GRR-Excellent Applications Application cases 1.LCO material assessment (evaluation of electrical properties of modified powder(LCO)) Parameter: 10-200MPa, 5MPa steps, keep 15s Results: When the Compact density of the modified powder is greater than 3.87g/cm3 (applied pressure > 75MPa), the conductivity of the modified powder is greatly improved. The effectiveness of the modification can be evaluated. 2.NCM material assessment (relation of powder resistivity and electrode: NCM material) Results Analyze By adjusting the Ni content in the ternary material, the powder conductivity increases with the increase of Ni content. Compared with three kinds of ternary electrodes with different Ni content, the conductivity of the electrode increases with the increasing of Ni content; Powder resistivity and electrode have the same trend ! 3.NCMA material assessment (relation of powder resistivity and electrode: NCMA material) Results Analyze The conductivity trend of the Quaternary powder and electrode under three different modification conditions is NCMAT > NCMA-2 > NCMA-3 ; The conductivity of NCMA43 in powder state is much smaller than that of the former two samples, but there is a small difference in the electrode plate, which may be related to the addition of conductive in the electrode plate, which reduces the difference between the powder. Powder resistivity and electrode have the same trend ! 4.LFP material assessment (relation of powder resistivity and electrode: LFP material) Results Analyze Compared with the LFP powder and electrode sheet under four different modification conditions, the conductivity trend of LFP powder and electrode sheet is as follows LFP-1>LFP-2>LFP-3>LFP-4 Powder resistivity and electrode have the same trend! 5.Graphite material assessment (compact density: parallel test 5 times) Parameter: 20~200MPa, 20MPa steps, keep 30s, relief 3MPa steps, keep 10s Results Analyze The cov of five parallel samples is less than 0.1% in the whole pressure range, which indicates that the equipment has good repeatability. With the increase of pressure, the Compact density of graphite material increases gradually and tends to be flat. The rebound of powder thickness under pressure and pressure relief reaches the maximum value at 80MPa, which indicates that this condition is the maximum pressure that the powder can bear, and if it is too large, the material structure is likely to be damaged. 6.Carbon material assessment (compact density VS resistivity: parallel test 5 times) Parameter: relief mode: 10~200MPa, 10MPa steps, keep 10s Results: The cov of five parallel samples is less than 0.3% in the whole pressure range, which indicates that the equipment has good repeatability. With the increase of pressure, the Compact density of carbon material increases gradually, and the compaction range is 0.5-0.9 g / cm3 . ♦ Part of the data comes from the partners, and the copyright belongs to the relevant parties. It can not be reproduced or used without consent High accuracy pressure system : Driven by servo motor. High accuracy displacement sensor : Precisely measure the variation of thickness. Specific clamp for resistivity & compaction density test of powder samples: Simplify the process of the powder loading and cleaning. Multi-functions : One-stop data collection of key parameters of pressure, resistance, thickness, temperature and humidity with high reliability, to provide a complete traceability for each result. Automatic measurement: Providing flexible measurement modes for different kinds of samples, and all the process parameter setting are integrated into a simple software control interface, with one-button to start a measurement. PRCDMS Software: 1.Pressure can be set willfully within the extent of max pressure. 2.The resistivity under different pressure can be measured in succession with controllable rate and interval of pressure scan. 3.Different data analysis curves can be generated, including resistivity-pressure curve, resistivity-thickness curve, compaction density-pressure curve, and pressure-thickness curve. 4.Two resistance data collection modes: interval time mode or automatic steady state condition determine mode. 5.Data statistical analysis functions. 6.Automatic generation of reports with the value of resistivity (or conductivity) and Compaction density. Integrated design : Integration of control and measurement systems for pressure, resistivity and thickness control and measurement systems. Application fields Carbonaceous Powders : Active materials of Lithium Ion Batteries and various electronic components (capacitor and resistor; etc.), including graphite, activated carbon, coke, carbon black, carbon fiber; carbon nanoparticles, etc. Metal oxide or metal composite powders: Active materials of Lithium Ion Batteries, conductive pastes, conductive coatings and other functional films, including LCO, LMO, LFR NCM, LTO copper powder; ITO powder; etc. Parameter Resistance range 1uΩ-1200mΩ Resistance accuracy ±0.05% Resistivity range 10^(-6)Ω cm-10^9Ω cm Conductivity range 10^(-9)^S/cm-10^6 S/cm Pressure range 0-200 MPa Pressure accuracy ±0.30%F.S Thickness range 0-8 mm Thickness accuracy/resolution 0.5um/±5um Max filling capacity Φ16*8 mm Temperature and humidity range 20-90%RH, 0-50℃ Temperature and humidity accuracy ±5%RH, ±2℃ Installation requirement Voltage 220V Voltage change tolerance ±10% Power consumption 2100W Environment temperature 25±5℃ Environmental humidity Humidity at 40℃ <80%RH Environmental magnetic field Away from intense electromagnetic fields Net weight 165kg Dimension(W*D*H) 370*580*1100 mm

-

Lab Pouch Cell Raw Materials Tester Powder Compaction Density Measurement System

Lab Pouch Cell Raw Materials Tester Powder Compaction Density Measurement System

Lab Pouch Cell Raw Materials Tester Powder Compaction Density Measurement System 1.Background The compaction density of the powder materials is not only related to its particle size and distribution, but also closely effect the capacity, internal resistance and the cycling performance of the produced lithium-ion batteries (LIBs). Theoretically speaking, the higher the compaction density, the higher the capacity of the LIB can be. Therefore, the compaction density is used as one of the key indicators to evaluating the energy density of materials. The compaction density is closely related to the intercalation and deintercalation of lithium ions during the cycling. Appropriate compaction density can effectively increase the capacity of the LIB reduce internal resistance, reduce polarization loss, and prolong the overall service life of the battery. On the one hand, the measurement of powder compaction density can be used as an effective index to monitor the differences between batches of powder materials, and on the other hand, it can be used as an effective means of R&D material evaluation and process optimization 2.Creative Solution The integrated design of the pressure application and thickness measurement modules can measure the compaction density under different quantitative pressures in real time; Fully automatic measurement software system, multi-parameter synchronous acquisition, intelligent and efficient testing process; Various testing modes such as single point, variable pressure, pressurization, and pressure relief can be optional, and the performance of the powder material can be evaluated in an all-round way; Equipped with machine inspection standard parts, preprocessing equipment and automatic demoulding equipment to ensure stable testing and improve overall efficiency 3.Measurement System Analysis (MSA) 4. Application Cases ① Effective evaluation of the compaction density of positive and negative electrode powders and conductive ② Monitor the long-term stability of the compaction density of the material; ③ Realize the effective evaluation of material stress-strain performance; ④ Realize the effective evaluation of material compression rebound performance; Application Case - Long-term Stability Evaluation of Nickel Cobalt Manganese Materials Parameters: 12MPa, 180MPa, hold pressure for 10s, test 3 groups every day, a total of 30 days of testing. Result analysis: The results of compaction density in 30 days are all less than ±3σ, and the long-term stability of the compaction density of this sample is good. Long-term stability of the compaction density of the sample can be monitored! Application Case - Lithium Iron Phosphate Material Evaluation Parameters: 10-200MPa, sampling points at an interval of 20MPa, holding pressure for 10s, a total of 5 groups of tests. Result analysis: The COV of the compaction density of 5 groups under each pressure is less than 0.5%, and the data fluctuation range is less than 0.05g/cm3, indicating that the the repeatability of this equipmentis good. It can evaluate the real-time change trend of the compaction density of the material with the increase of the pressure! Application Case-Lithium Cobalt Oxide Material Evaluation Parameters: 10-200MPa, sampling points at intervals of 20MPa, holding pressure for 10s, and tested 4 samples in total. Result analysis: The results show that the stress-strain curves of the four lithium cobalt oxide materials are different during the compression process, and the compression properties of the materials can be further evaluated in combination with the material particle size distribution. It can help R&D to evaluate the stress-strain performance of materials Application Case-Graphite and Carbon Material Evaluation Parameters: 10-200MPa, sampling points at intervals of 20MPa, hold pressure for 10s, release pressure to 3MPa, hold pressure for 10s, test 4 samples in total. Result analysis: The results show that the thickness rebound of graphite and carbon materials during the process of pressurization and decompression are different, and the rebound of graphite material is greater than that of hard carbon. It can help research and development to evaluate the compression rebound performance of materials! Parameters and installation requirements Model PCD1000 PCD2000 Max pressure 1000kg 5000kg Pressure measurement resolution/accuracy 0.1kg/±0.3%FS Thickness measurement range 0-8mm Thickness measurement resolution/accuracy 0.5um/±10um Maximum capacity that can be filled Φ13*8mm(can be customized) Power supply 200-240V/50-60Hz Voltage variation tolerance ±10% Power 450W 2100W Environment temperature 10-35C, 13mm*8mm(customizable) Environment humidity <80%RH(no condensation) Net weight 85kg 250kg Size W330*D402*H780mm W370*D565*H1200mm

-

Lab Powder Compaction Density Analyzer For Lithium Battery R&D

Lab Powder Compaction Density Analyzer For Lithium Battery R&D

Lab Powder Compaction Density Analyzer For Lithium Battery R&D 1.Background The compaction density of the powder materials is not only related to its particle size and distribution, but also closely effect the capacity, internal resistance and the cycling performance of the produced lithium-ion batteries (LIBs). Theoretically speaking, the higher the compaction density, the higher the capacity of the LIB can be. Therefore, the compaction density is used as one of the key indicators to evaluating the energy density of materials. The compaction density is closely related to the intercalation and deintercalation of lithium ions during the cycling. Appropriate compaction density can effectively increase the capacity of the LIB reduce internal resistance, reduce polarization loss, and prolong the overall service life of the battery. On the one hand, the measurement of powder compaction density can be used as an effective index to monitor the differences between batches of powder materials, and on the other hand, it can be used as an effective means of R&D material evaluation and process optimization 2.Creative Solution The integrated design of the pressure application and thickness measurement modules can measure the compaction density under different quantitative pressures in real time; Fully automatic measurement software system, multi-parameter synchronous acquisition, intelligent and efficient testing process; Various testing modes such as single point, variable pressure, pressurization, and pressure relief can be optional, and the performance of the powder material can be evaluated in an all-round way; Equipped with machine inspection standard parts, preprocessing equipment and automatic demoulding equipment to ensure stable testing and improve overall efficiency 3.Measurement System Analysis (MSA) 4. Application Cases ① Effective evaluation of the compaction density of positive and negative electrode powders and conductive ② Monitor the long-term stability of the compaction density of the material; ③ Realize the effective evaluation of material stress-strain performance; ④ Realize the effective evaluation of material compression rebound performance; Application Case - Long-term Stability Evaluation of Nickel Cobalt Manganese Materials Parameters: 12MPa, 180MPa, hold pressure for 10s, test 3 groups every day, a total of 30 days of testing. Result analysis: The results of compaction density in 30 days are all less than ±3σ, and the long-term stability of the compaction density of this sample is good. Long-term stability of the compaction density of the sample can be monitored! Application Case - Lithium Iron Phosphate Material Evaluation Parameters: 10-200MPa, sampling points at an interval of 20MPa, holding pressure for 10s, a total of 5 groups of tests. Result analysis: The COV of the compaction density of 5 groups under each pressure is less than 0.5%, and the data fluctuation range is less than 0.05g/cm3, indicating that the the repeatability of this equipmentis good. It can evaluate the real-time change trend of the compaction density of the material with the increase of the pressure! Application Case-Lithium Cobalt Oxide Material Evaluation Parameters: 10-200MPa, sampling points at intervals of 20MPa, holding pressure for 10s, and tested 4 samples in total. Result analysis: The results show that the stress-strain curves of the four lithium cobalt oxide materials are different during the compression process, and the compression properties of the materials can be further evaluated in combination with the material particle size distribution. It can help R&D to evaluate the stress-strain performance of materials Application Case-Graphite and Carbon Material Evaluation Parameters: 10-200MPa, sampling points at intervals of 20MPa, hold pressure for 10s, release pressure to 3MPa, hold pressure for 10s, test 4 samples in total. Result analysis: The results show that the thickness rebound of graphite and carbon materials during the process of pressurization and decompression are different, and the rebound of graphite material is greater than that of hard carbon. It can help research and development to evaluate the compression rebound performance of materials! Parameters and installation requirements Model PCD1000 PCD2000 Max pressure 1000kg 5000kg Pressure measurement resolution/accuracy 0.1kg/±0.3%FS Thickness measurement range 0-8mm Thickness measurement resolution/accuracy 0.5um/±10um Maximum capacity that can be filled Φ13*8mm(can be customized) Power supply 200-240V/50-60Hz Voltage variation tolerance ±10% Power 450W 2100W Environment temperature 10-35C, 13mm*8mm(customizable) Environment humidity <80%RH(no condensation) Net weight 85kg 250kg Size W330*D402*H780mm W370*D565*H1200mm

-

Lab Powder Compaction Density Analyzer For Lithium Battery R&D

Lab Powder Compaction Density Analyzer For Lithium Battery R&D

Lab Powder Compaction Density Analyzer For Lithium Battery R&D 1.Background The compaction density of the powder materials is not only related to its particle size and distribution, but also closely effect the capacity, internal resistance and the cycling performance of the produced lithium-ion batteries (LIBs). Theoretically speaking, the higher the compaction density, the higher the capacity of the LIB can be. Therefore, the compaction density is used as one of the key indicators to evaluating the energy density of materials. The compaction density is closely related to the intercalation and deintercalation of lithium ions during the cycling. Appropriate compaction density can effectively increase the capacity of the LIB reduce internal resistance, reduce polarization loss, and prolong the overall service life of the battery. On the one hand, the measurement of powder compaction density can be used as an effective index to monitor the differences between batches of powder materials, and on the other hand, it can be used as an effective means of R&D material evaluation and process optimization 2.Creative Solution The integrated design of the pressure application and thickness measurement modules can measure the compaction density under different quantitative pressures in real time; Fully automatic measurement software system, multi-parameter synchronous acquisition, intelligent and efficient testing process; Various testing modes such as single point, variable pressure, pressurization, and pressure relief can be optional, and the performance of the powder material can be evaluated in an all-round way; Equipped with machine inspection standard parts, preprocessing equipment and automatic demoulding equipment to ensure stable testing and improve overall efficiency 3.Measurement System Analysis (MSA) 4. Application Cases ① Effective evaluation of the compaction density of positive and negative electrode powders and conductive ② Monitor the long-term stability of the compaction density of the material; ③ Realize the effective evaluation of material stress-strain performance; ④ Realize the effective evaluation of material compression rebound performance; Application Case - Long-term Stability Evaluation of Nickel Cobalt Manganese Materials Parameters: 12MPa, 180MPa, hold pressure for 10s, test 3 groups every day, a total of 30 days of testing. Result analysis: The results of compaction density in 30 days are all less than ±3σ, and the long-term stability of the compaction density of this sample is good. Long-term stability of the compaction density of the sample can be monitored! Application Case - Lithium Iron Phosphate Material Evaluation Parameters: 10-200MPa, sampling points at an interval of 20MPa, holding pressure for 10s, a total of 5 groups of tests. Result analysis: The COV of the compaction density of 5 groups under each pressure is less than 0.5%, and the data fluctuation range is less than 0.05g/cm3, indicating that the the repeatability of this equipmentis good. It can evaluate the real-time change trend of the compaction density of the material with the increase of the pressure! Application Case-Lithium Cobalt Oxide Material Evaluation Parameters: 10-200MPa, sampling points at intervals of 20MPa, holding pressure for 10s, and tested 4 samples in total. Result analysis: The results show that the stress-strain curves of the four lithium cobalt oxide materials are different during the compression process, and the compression properties of the materials can be further evaluated in combination with the material particle size distribution. It can help R&D to evaluate the stress-strain performance of materials Application Case-Graphite and Carbon Material Evaluation Parameters: 10-200MPa, sampling points at intervals of 20MPa, hold pressure for 10s, release pressure to 3MPa, hold pressure for 10s, test 4 samples in total. Result analysis: The results show that the thickness rebound of graphite and carbon materials during the process of pressurization and decompression are different, and the rebound of graphite material is greater than that of hard carbon. It can help research and development to evaluate the compression rebound performance of materials! Parameters and installation requirements Model PCD1000 PCD2000 Max pressure 1000kg 5000kg Pressure measurement resolution/accuracy 0.1kg/±0.3%FS Thickness measurement range 0-8mm Thickness measurement resolution/accuracy 0.5um/±10um Maximum capacity that can be filled Φ13*8mm(can be customized) Power supply 200-240V/50-60Hz Voltage variation tolerance ±10% Power 450W 2100W Environment temperature 10-35C, 13mm*8mm(customizable) Environment humidity <80%RH(no condensation) Net weight 85kg 250kg Size W330*D402*H780mm W370*D565*H1200mm

-

Lab Powder Wet Vibrating Screen Analyzer For Pouch Cell R&D

Lab Powder Wet Vibrating Screen Analyzer For Pouch Cell R&D

Lab Powder Wet Vibrating Screen Analyzer For Pouch Cell R&D Introduction Background: manual screening and mixing method with wooden stick are adopted.. At least two people are required to operate at the same time, and 3-4 people are required when the quantity of incoming materials is large; Problem points: poor operating environment, waste of manpower, low efficiency, introduction of manual methods,and poor consistency. Creative Solutions Advantages 1. Operation automation: realize the automation of powder screening process; 2. Manpower reduction:it can reduce the manpower to only one operator 3. Consistency improvement: it can reduce the differences in personnel skills and improve the consistency level; 4. Efficiency improvement: shorten testing time; 5. Convenient cleaning: all adopt quick-release and quick-change structure; 6. The screening part is of non-metallic structure: it can avoid the interference of metallic particles Equipment parameters Items Parameter Mixing drum 10kg Level sensor tolerance ±3mm Amplitude or speed 0.2-3mm Screenable diameter 1200 mesh, 0.014mm (the screen can be replaced as required) Screening mode Wet sieve Installation requirements Items Parameter Equipment voltage 380V Number of power interfaces 1 Water source interface/number of interfaces Deionized water/2 Size 1000*1000*1500mm

-

Lab Wet Vibrating Screen System Testing Equipment For Battery Powder R&D

Lab Wet Vibrating Screen System Testing Equipment For Battery Powder R&D

Lab Wet Vibrating Screen System Testing Equipment For Battery Powder R&D Introduction Background: manual screening and mixing method with wooden stick are adopted.. At least two people are required to operate at the same time, and 3-4 people are required when the quantity of incoming materials is large; Problem points: poor operating environment, waste of manpower, low efficiency, introduction of manual methods,and poor consistency. Creative Solutions Advantages 1. Operation automation: realize the automation of powder screening process; 2. Manpower reduction:it can reduce the manpower to only one operator 3. Consistency improvement: it can reduce the differences in personnel skills and improve the consistency level; 4. Efficiency improvement: shorten testing time; 5. Convenient cleaning: all adopt quick-release and quick-change structure; 6. The screening part is of non-metallic structure: it can avoid the interference of metallic particles Equipment parameters Items Parameter Mixing drum 10kg Level sensor tolerance ±3mm Amplitude or speed 0.2-3mm Screenable diameter 1200 mesh, 0.014mm (the screen can be replaced as required) Screening mode Wet sieve Installation requirements Items Parameter Equipment voltage 380V Number of power interfaces 1 Water source interface/number of interfaces Deionized water/2 Size 1000*1000*1500mm

-

20T Precision CNC Servo Hydraulic Press Forming Machine for Ceramic Powder Molding

20T Precision CNC Servo Hydraulic Press Forming Machine for Ceramic Powder Molding

-

Food Chemical Micro Powder Agate Bowl Grinder with Agate Mantle

Food Chemical Micro Powder Agate Bowl Grinder with Agate Mantle

-

Lab 5000ML Small Mixing Test Machine Non Metal Powder Mixer with Touch Screen

Lab 5000ML Small Mixing Test Machine Non Metal Powder Mixer with Touch Screen

-

Laboratory 2L or 5L 3D Powder Mixer for Metal or Non-metal Powder Mixing Optional PP Material Jar

Laboratory 2L or 5L 3D Powder Mixer for Metal or Non-metal Powder Mixing Optional PP Material Jar

1100mL Vacuum Planetary Centrifugal Mill for Lithium Battery& Mixer with Two jars & Independent Speed Controlled & Mixer with Two jars

-

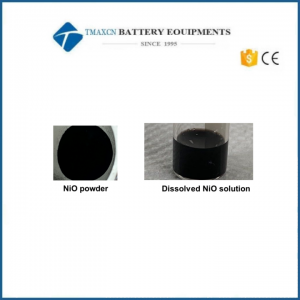

Perovskite Special Nano Nickel Oxide Powder

Perovskite Special Nano Nickel Oxide Powder

Sales Manager: Gia Email: Gia@tmaxlaboratory.com Wechat: Dingqiuna Whatsapp:+86 131 7450 6016 Skype: gia@tmaxcn.com

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588