products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

1000 Kg Pneumatic Heat Press machine up to 200C with Programmable Pressure Controller

1000 Kg Pneumatic Heat Press machine up to 200C with Programmable Pressure Controller

1000 Kg Pneumatic Heated Lab Press up to 200°C with Programmable Pressure Controller TMAX-RY200 is a Pneumatic Press with precision constant pressure controller within 1000 kg and 200°C . It is designed for testing the effect of pressure on solid state battery performance, also can be used as jig tool for flow cell and any research that need precision pressure.. It also can be used as heated press up to 200°C if remove pressure sensor.

-

30L Planeyary Vacuum Water And Powder Mixing Machine

30L Planeyary Vacuum Water And Powder Mixing Machine

1 TMAX-XFZH30 Vacuum Planetary Mixer is a vacuum mixing machine with 30 liter containers and complete accessories for immediate use. 2 The TMAX-XFZH30 adopts Low-speed stirrer scattered and installed on the high-speed shaft of zigzag dispersion plate with both rotation and revolution; At the same time combined with stirring Plasma low clearance design, low speed impeller make the material produces strong kneading movement interference and control/up and down and circular motion; High speed dispersion plate is strong shear break up material, So as to ultimately ensure that materials are fully dispersed and mixed evenly (mixed). 3 TMAX-XFZH30 Vacuum Planetary Mixer is excellent for preparing LiCoO3, LiFePO4, phosphors and ceramic slurry with excellent results in dispersion and uniformity.

-

Lithium cobalt oxide LiCoO2 powder for lithiumion battery cathode materials

Lithium cobalt oxide LiCoO2 powder for lithiumion battery cathode materials

Feature: 1. The electrochemical performance is superior a. The average cycle capacity attenuation per cycle <0.05% b. Discharge specific capacity for the first time >135mAh/g c. 3.6 V first discharge platform rate > 85% 2. The processing performance 3. Tap density is big, help to improve volume specific storage battery 4. Product performance is stable, good consistency Application: the positive active material of the lithium ion battery, More used in digital products batteries. Two sides are coated with aluminum foil.

-

High Grade Li-ion Battery Material PVDF Powder

High Grade Li-ion Battery Material PVDF Powder

Application: Binder for lithium ion battery positive electrode active material, generally mixed with NMP solvent Appearance: White powder Usage: 761A is a kind of powder - like polyvinyl fluoride product, which has good solubility in some solvents. Compared with other brands of 761A, PVDF is more suitable as a lithium battery electrode binder material, less than similar products, thereby increasing the capacity of the battery. 761A is a kind of polymer material with high dielectric constant, which has high viscosity and adhesion in a certain solvent. The lithium battery membrane electrode material made of 761A has good chemical stability, temperature stability and good workability. Item Unit Test way Stand Purity % / More than 99.9% Density g/cm3 D792 1.77-1.80 Melting point ℃ D3418 165-172 molecular weight / / 65-75 (230℃,5kg) / Melt Flow Index g/10min D3835 1-2 Characteristic viscosity dl/g DMA,30℃ 1.0-2.0 Rotary viscometer Mpa.s 1g/10ml NMP,30℃ >2500 solubility / NMP/DMP,30℃,1hr clear solution Shao Hardness D D2240 76-80 shrinking percentage % D955 2.0-3.0 Water absorption % D570 0.01-0.03 Thermal decomposition (1% Wt loos in air) ℃ TGA 370-390

-

High Purity Polyvinylidene Fluoride Powder For Litium Battery Cathode Materials

High Purity Polyvinylidene Fluoride Powder For Litium Battery Cathode Materials

Application: Binder for lithium ion battery positive electrode active material, generally mixed with NMP solvent Appearance: White powder Usage: 761A is a kind of powder - like polyvinyl fluoride product, which has good solubility in some solvents. Compared with other brands of 761A, PVDF is more suitable as a lithium battery electrode binder material, less than similar products, thereby increasing the capacity of the battery. 761A is a kind of polymer material with high dielectric constant, which has high viscosity and adhesion in a certain solvent. The lithium battery membrane electrode material made of 761A has good chemical stability, temperature stability and good workability.

-

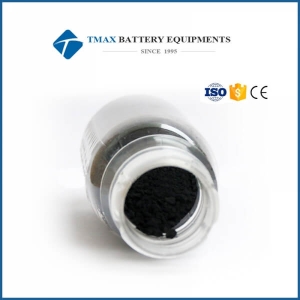

LiFePO4 Powder Used For Li-ion Battery Cathode Materials

LiFePO4 Powder Used For Li-ion Battery Cathode Materials

Lithium iron phosphate black powder Main application: Is the positive active material of the power battery. Mainly used for energy storage/electric toolsght electric vehicle/miner's lamp/mobile power and so on. Main characteristics: 1.High energy density, Its theoretical specific capacity is 170 mAh/g, Actual product specific capacity can be more than 140 mAh/g (0.2 C, 25 ° C); 2. High security, is the safety of lithium ion battery cathode material; Do not contain any harmful heavy metals; 3.long life: In 100% DOD (depth of discharge) conditions, can charge and discharge more than 2000 times; (reason: lithium iron phosphate lattice stability is good, the lithium ions embedded and emergence of lattice impact is not big, so it has good reversibility. The deficiencies are ionic conductivity electrode is poor, not suitable for large current charge and discharge, stuck in applications. Solution: in the electrode coating on the surface of conductive material, doped modified electrode. ) The service life of the lithium iron phosphate battery with temperature, temperature too low or too high in the charging and discharging process and use process produce greatly bad hidden trouble. Electric cars use especially in northern China, in the fall and winter normal power supply of the lithium iron phosphate batteries or power supply is too low, need to adjust its working environment temperature to maintain its performance. At present, the domestic solve the lithium iron phosphate battery temperature working environment should be considered space limitations, the common solution is to use the aerogel blanket as a thermal insulation layer.

-

Lithium Cobalt Oxide Powder For Lithium Battery Cathode

Lithium Cobalt Oxide Powder For Lithium Battery Cathode

Feature: 1. The electrochemical performance is superior a. The average cycle capacity attenuation per cycle <0.05% b. Discharge specific capacity for the first time >135mAh/g c. 3.6 V first discharge platform rate > 85% 2. The processing performance 3. Tap density is big, help to improve volume specific storage battery 4. Product performance is stable, good consistency Application: the positive active material of the lithium ion battery, More used in digital products batteries. Two sides are coated with aluminum foil.

-

Polyvinylidene Fluoride PVDF Powder

Polyvinylidene Fluoride PVDF Powder

Feature: 1. The electrochemical performance is superior a. The average cycle capacity attenuation per cycle <0.05% b. Discharge specific capacity for the first time >135mAh/g c. 3.6 V first discharge platform rate > 85% 2. The processing performance 3. Tap density is big, help to improve volume specific storage battery 4. Product performance is stable, good consistency Application: the positive active material of the lithium ion battery, More used in digital products batteries. Two sides are coated with aluminum foil.

-

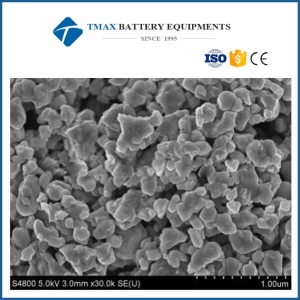

Super Conductive Carbon Black Powder For Lithium Battery materials

Super Conductive Carbon Black Powder For Lithium Battery materials

-

H Shape Three Port Electrolysis Cell Used For Electrode Reaction Research

H Shape Three Port Electrolysis Cell Used For Electrode Reaction Research

SPECIFICATIONS In the battery, electrode generally refers to the redox reaction occurs and the electrolyte solution position. The electrode is divided into positive and negative, generally positive as anode, electron gain, reduction reaction occurs, the negative cathode oxidation reaction occurs, the loss of electronic. The electrode can be metal or non metal, as long as they can exchange electrons with the electrolyte solution, which become the electrode. In electrochemical analysis solution concentration, electrode is converted into an electric signal sensor. The glass cell is used for electrode reaction for laboratory research.

-

Lithium Titanate Powder LTO For Li-ion Battery Cathode Materials

Lithium Titanate Powder LTO For Li-ion Battery Cathode Materials

LTO/ Lithium titanate/Lithium Titanium Oxide/ LiTiO / Li4Ti5O12(Carbon coating is black powder, no carbon coating is white powder). At present, it is mainly used in energy storage battery, EV battery, special power supply, super capacitor and so on. 1. Advantage: High safety, long service life, high power. 2. Shortcoming: Low energy density. 3. Application: Anode materials for lithium ion batteries.

-

Red Powder Cobalt Sulphate CoSO4 7H2O for Industry

Red Powder Cobalt Sulphate CoSO4 7H2O for Industry

-

High Purity Carboxymethyl Cellulose Powder CMC Battery For Lithium Battery Anode Materials

High Purity Carboxymethyl Cellulose Powder CMC Battery For Lithium Battery Anode Materials

Appear: White powder Application: Lithium-ion battery anode material, for anti-precipitation

-

Activated Carbon Powder For Organic System

Activated Carbon Powder For Organic System

High Purity Conductive Carbon Black Powder For Battery Materials Product characteristics : 1. Excellent conductivity 2. High purity and low impurities 3. Prevent the charge accumulation

-

Carboxymethyl Cellulose CMC Powder Lithium Battery Anode Material

Carboxymethyl Cellulose CMC Powder Lithium Battery Anode Material

Appear: White powder Application: Lithium-ion battery anode material, for anti-precipitation

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588