products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

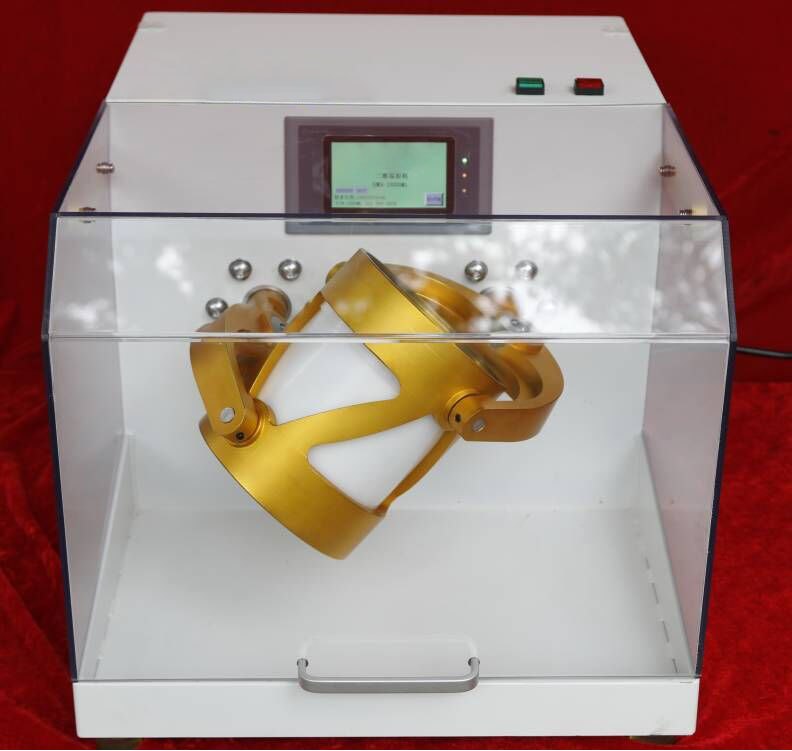

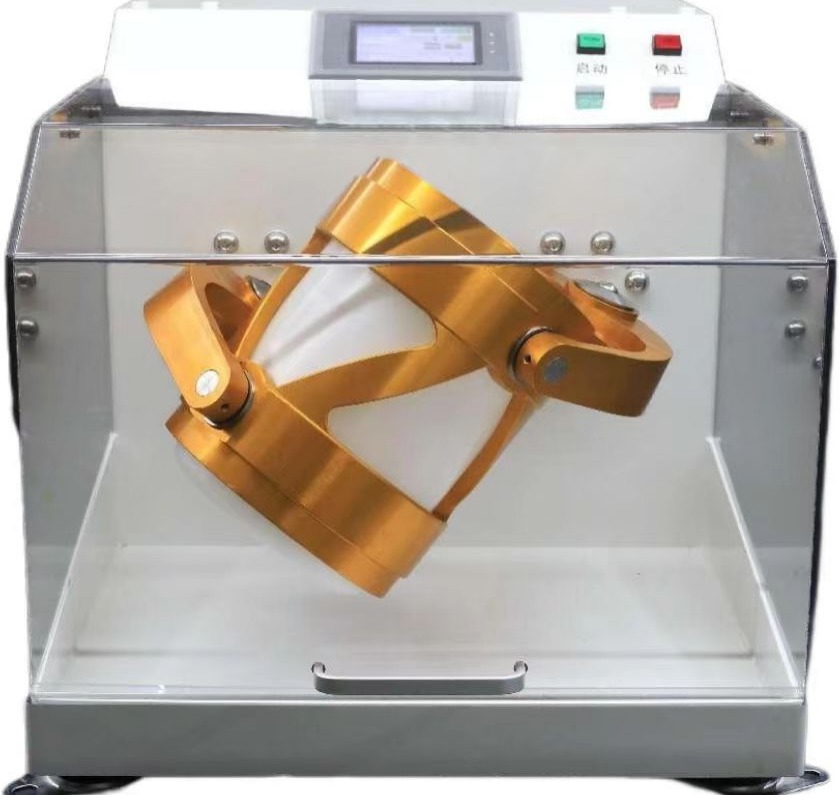

Laboratory 2L or 5L 3D Powder Mixer for Metal or Non-metal Powder Mixing Optional PP Material Jar

Model Number:

TMAX-SWHCompliance:

CE CertifiedWarranty:

One year limited with lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Laboratory 2L or 5L 3D Powder Mixer for Metal or Non-metal Powder Mixing Optional PP Material Jar

Brief introduction

Laboratory mixer is also called three-dimensional mixer or swing mixer. It is mainly used for mixing powder materials with different densities, different particle sizes and high uniformity. The product is mixed in a fully closed container, and different containers can be replaced to achieve the best capacity effect. The experiments of different formulations can be done separately to avoid mutual contamination. Containers are easy to clean.

Working principle

According to the Schatz three-link geometry principle, the laboratory mixing machine simultaneously adopts three kinds of motion, namely rotation, translation and reversal. When working, the three-dimensional space movement of the mixing tank makes the mixed material always in the pulsating state of rhythm change, so as to achieve the combination of high mixing effect and short mixing time. The laboratory mixer is fully enclosed for dust-free production and easy to clean.

Laboratory mixer can optionally install different capacity tank and test tube tooling with diameter less than 130MM and length less than 240MM below 2L.

Main feature

Easy to maintain, truly realize dust-free production, easy to clean, and even mixing.

Application field

The laboratory mixer is suitable for all occasions that require short mixing time and high uniformity of mixing effect, such as industrial production, scientific research, laboratory development, etc.

Diamond tools, electronic technology, sintered powder metal, ceramic industry, cosmetics industry, chemical industry, food industry

Laboratory mixer

The mixing container can be filled in a variety of different sizes and shapes, from small test tubes to large 2-liter mixing tanks.

Containers are quickly fixed with special clamps.

The container can fit into a standard 2-litre tank, and with the help of a jig, smaller mixing tanks can be used.

Can set 0-100RPM stepless speed control Settings, man-machine dialogue, touch screen Settings, easy to use. System 10 programs, each program 2 steps forward and reverse, each step can set the speed and time. Unmatched handling gives you a perfectly blended product.

Laboratory Powder Mixer (Three-dimensional mixing instrument)

Model:SWH-2000ML

Use:Metal or non-metal powder mixing

Standard container:2200ML

Maximum capacity:2000ML (Max. 6KG)

Small container extension:Use an adapter sleeve or place in a standard tank to plug and secure

Speed:30~100rpm stepless speed control, according to the actual needs of users, any input, adjust 1rpm;

Motor:The starting torque of low-speed high-torque precision speed motor is 8N.M, the motor is accurate to 0.45 degrees/revolution, and the spindle torque is 24N.M

Transmission belt:Use 5M synchronous belt to ensure speed accuracy to an error of less than 0.2RPM/ min. Synchronous belt ultimate tensile strength 4800N Maximum allowable tension: 1600N, the belt can withstand 30N.M torque on this machine

C-type support arm:MG-aluminum alloy 7075 sheet metal CNC precision machining molding, material strength close to Q235 steel

Cylinder:6061T6 high strength tube material CNC precision machining molding

Bearing:The sealant cover is maintenance-free, all pre-tightened assembly without any gap, improving the overall life several times

Setting time:Forward reversal 2 steps: 50 minutes per step (positive and negative total 100 minutes), accuracy 1s, can cycle 20 times;

Parameter storage capacity:10 groups;

Control system:Man-machine dialogue, Chinese interface, touch screen operation;

Working principle:Rotation, translation, reverse three-dimensional space movement;

Machine back to the origin: The machine automatically finds the correct origin after the natural stop

Safety protection:PC bullet-proof glass shield, lock and stop the movement when the machine stops, prevent the finger from being hurt by the rotation of the material, open the shield and stop working immediately;

Applicable temperature and humidity:10~40 ℃; 20~60%RH;

Voltage:AC220V±5%; 1-Phase; 50~60Hz;

Size: L500×W635×H430mm;

Weight:35Kg.

Equipment features:Easy to maintain, truly realize dust-free production, easy to clean, and even mixing

Standard accessories:

No. |

Mixing tank capacity |

Material |

Qty |

Remark |

1 |

2.2L |

PE |

2 |

Made by TMAXCN |

2 |

1150ML |

PP |

2 |

1 set of fixtures purchased |

3 |

760ML |

PP |

2 |

1 set of fixtures purchased |

4 |

250ML |

Glass |

2 |

1 set of fixtures purchased |

5 |

100ML |

Glass |

2 |

1 set of fixtures purchased |

PE (polyethylene) has excellent chemical resistance and is not attacked by strong acids or bases, solvents, and can resist mild oxidants and reducing agents.

PP (polypropylene) has good acid, alkali and salt resistance. Corrosion properties of solvents and other chemicals

Standard accessories:

Optional accessories:

Laboratory Powder Mixer (Three-dimensional mixing instrument)

Model:SWH-5000ML

Use:Metal or non-metal powder mixing

Standard container:5000ML

Maximum capacity:4500ML(Max.9KG)

Small container extension:Use an adapter sleeve or place in a standard tank to plug and secure

Speed:20 to 60rpm stepless speed control, depending on the actual requirements of the user input, adjust 1rpm

Setting time:Forward reversal 2 steps: 50 minutes per step (positive and negative total 100 minutes), accuracy 1s, can cycle 20 times;

Parameter storage capacity:10 groups;

Control system:Man-machine dialogue, Chinese interface, touch screen operation;

Working principle:Rotation, translation, reverse three-dimensional space movement;

Machine back to the origin:The machine automatically finds the correct origin after the natural stop

Safety protection:PC bullet-proof glass shield, lock and stop the movement when the machine stops, prevent the finger from being hurt by the rotation of the material, open the shield and stop working immediately;

Applicable temperature and humidity:10~40 ℃; 20~60%RH;

Voltage:AC220V±5%; 1-Phase; 50~60Hz;

Size:L528×W750×H500mm

Weight:60Kg

Equipment features:Easy to maintain, truly realize dust-free production, easy to clean, and even mixing.

Standard accessories:

No. |

Mixing tank capacity |

Material |

Qty |

Remark |

1 |

5L |

PE |

2 |

Made by TMAXCN |

2 |

2.2L |

PE |

2 |

Made by TMAXCN |

3 |

1150ML |

PP |

2 |

1 set of fixtures purchased |

4 |

760ML |

PP |

2 |

1 set of fixtures purchased |

5 |

250ML |

Glass |

2 |

1 set of fixtures purchased |

6 |

100ML |

Glass |

2 |

1 set of fixtures purchased |

PE (polyethylene) has excellent chemical resistance and is not attacked by strong acids or bases, solvents, and can resist mild oxidants and reducing agents.

PP (polypropylene) has good acid, alkali and salt resistance. Corrosion properties of solvents and other chemicals.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588