products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

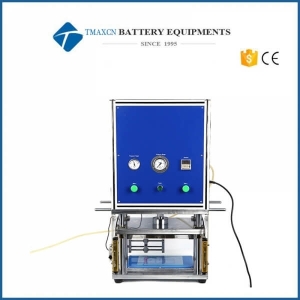

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Precision Die Cutter for Pouch Cell electrode Sheet

Precision Die Cutter for Pouch Cell electrode Sheet

Precision Die Cutter for Pouch Cell electrode Sheet TMAX-MQ280 is a CE Certified Precision electrode die cutter with optional size range). It is a necessary tool in the production line of pouch cell to produce specific shapes of cathodes and anodes with current collector tabs. The size of the electrodes it cuts perfectly matches the standard pouches made by the TMAX-SCK200 cup forming machine, and the shape of the electrodes it produces is also handy for the latter processing steps. The IR sensor (Safety Curtain) built in the front of the machine ensures operation safety when electrode sheets are fed from the front.

-

Battery Electrode and Separator Slitter Slitting Machine

Battery Electrode and Separator Slitter Slitting Machine

Electrode Slitting/Cutting Machine For Sale The slitting machine TMAX-MSK-300 is a CE Certified semi-automatic slitting machine (roll slitting) for preparing electrode of cylinder batteries in R&D laboratories.

-

Lithium Battery Electrode Cutting Machine for 18650 26650 21700 32650 4680 Cylindrical Cell

Lithium Battery Electrode Cutting Machine for 18650 26650 21700 32650 4680 Cylindrical Cell

-

Slitting Machine for Cylindrical Cell Electrode Cutting

Slitting Machine for Cylindrical Cell Electrode Cutting

1 TMAX-MQ300A semi-automatic electrode die cutter is mainly used for pouch cell electrode sheet cut for stacking pouch cell battery. It is a necessary tool in the production line of pouch cell to produce specific shapes of cathodes and anodes with current collector tabs. 2 This Semi Automatic Die Cutter machine adopts Safety Curtain built in the front of the machine and double start button ensures operation safety when electrode sheets are fed from the front. 3 High speed, high accuracy, long lifetime to make cutted electrode without burr, to get a good consistency. 4 This model has max die dimension with 200*300mm, if need other models, please choose the TMAX-JD-500model with max die size up to 500*500mm.

-

Automatic Slitting Machine for Li ion Battery Electrode Sheets Crosscutting

Automatic Slitting Machine for Li ion Battery Electrode Sheets Crosscutting

Automatic Slitting Machine for Li ion Battery Electrode Sheets Crosscutting Introduction This product is mainly used for single-piece cutting of positive and negative plates of lithium batteries. The cutting length, quantity and speed can be set arbitrarily, and it can be cut separately. This machine has an automatic unwinding function. The automatic unwinding and automatic stop are controlled by the tension frame. The speed is adjustable during unwinding, and the feeding axis is pneumatic. The shaft is expanded and it is convenient to load and unload. Main features *The cutting length, quantity and speed can be set arbitrarily, and can be cut separately; * Unwinding automatically adjusts the tension; *Continuous cutting, fixed length and cursor tracking two modes are optional, adapt to multi-segment cutting, the compensation before and after the incision can be set; * The width is 10~300mm, and the length is set arbitrarily within 1~9999 mm. *The machine adopts PLC man-machine interface control, easy to use and operate. *Exquisite appearance, the sheet metal adopts three-dimensional geometric design, which is simple and beautiful; *Easy to operate, safe and reliable, small size; Technical parameter Unwinding The unwinding air shaft is fixed, and the unwinding tension uses automatic unwinding and constant tension Fixed length cutting speed 5~250mm/s Chasing color cutting speed 5~150mm/s Unwinding diameter (Max) 250mm Burr condition ≦25um Power supply 220V/50Hz Power 1.2KW Compressed air 0.5Mpa~0.8 Mpa Scope of application Width 300mm, length 1~9999 mm cutting Cutting accuracy Fixed length using servo system and color code sensor to track the fixed length, high accuracy, cutting accuracy within the adjustable range ± 0.3mm Dimensions L700*W700*H1000mm (the length of the guide plate is 800 and the total length of the machine is 1500mm) Weight About 240kg

-

500mmW Roll to Roll Slitting Machine for Electrode Manufacturing

500mmW Roll to Roll Slitting Machine for Electrode Manufacturing

-

Sodium-Ion Battery Roll to Roll Slitting Machine for Electrode Manufacturing

Sodium-Ion Battery Roll to Roll Slitting Machine for Electrode Manufacturing

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588