products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

CCD Visual Inspection Machine Tester

Model Number:

TMAX-CCD101Input Power:

1.5kWNet Weight:

300kgCompliance:

CE CertifiedWarranty:

1 yearPlace of Origin:

ChinaMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

45 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Prismatic Battery Stacking Pressing MachineNext:

Prismatic Lithium Battery Cell Stacking and Pressing Machine

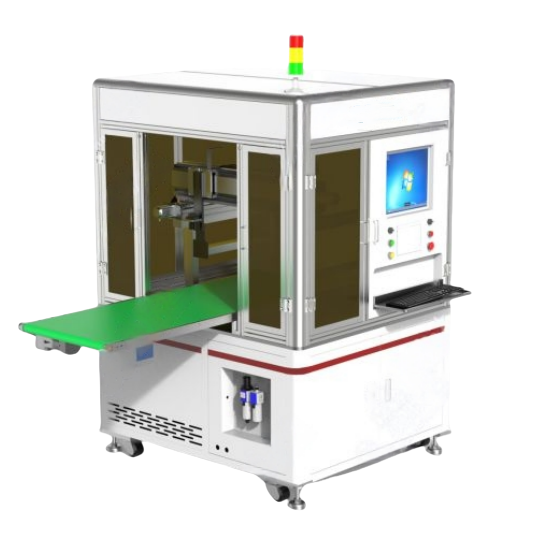

CCD Visual Inspection Machine Tester

TMAX-CCD101 consists of a continuous belt assembly line, camera, light source, electrical control part, etc. Firstly, manually place the battery pack on the conveyor belt and position it using a positioning fixture. The battery module flows to the detection area through the conveyor belt, and the equipment automatically compares and detects by taking photos to determine whether there is a matching error in the positive and negative polarity of the module. After comparison and detection, there is no abnormality. The battery module flows to the next station. When an abnormality is detected, the equipment triggers an alarm, which is manually confirmed, intervened, and eliminated to avoid flowing to the next operating position.

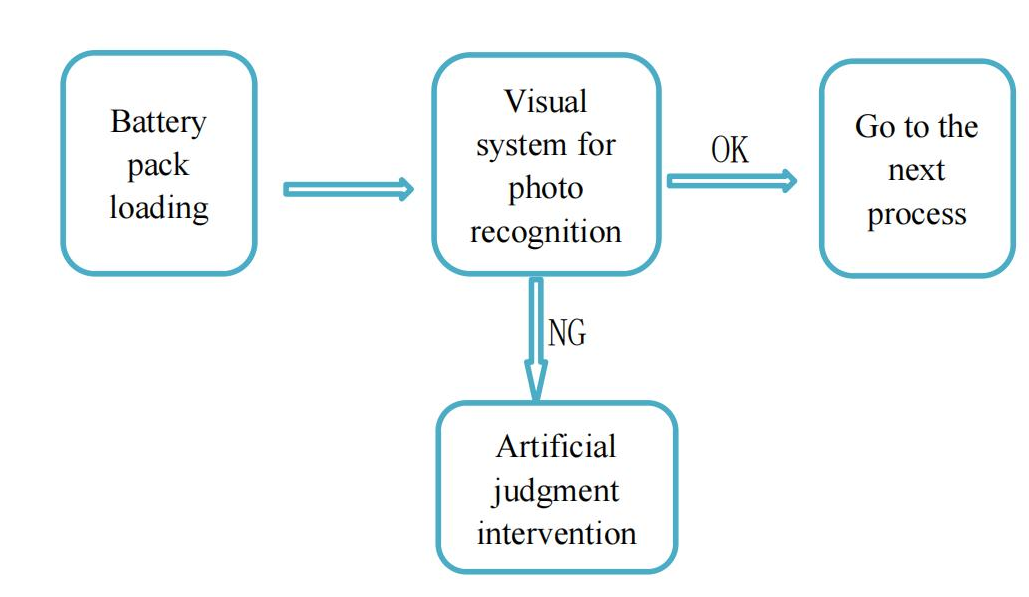

Ⅱ、Workflow:

Ⅲ、Machine performance characteristics:

3、Programming is simple, and judgment criteria can be set according to different combinations of battery cells. It can store any set of programming files.

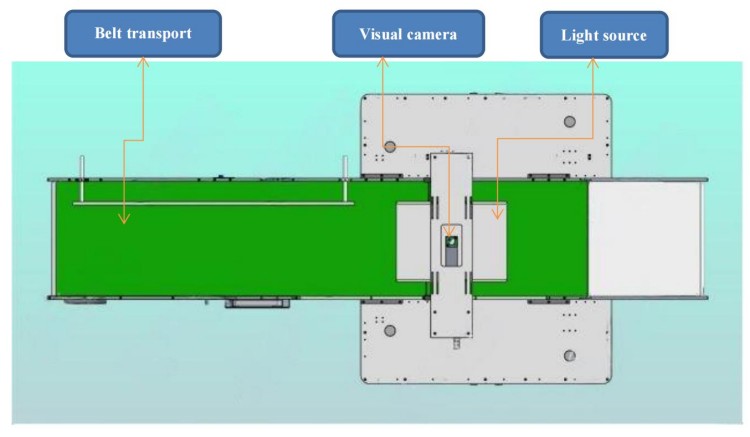

Ⅳ、Overall layout plan:

Ⅴ、Equipment parameters:

Basic parameters |

||

1 |

Weight |

About 300Kg |

2 |

Equipment size |

L*W*H:2800mm*1385mm*1935mm |

3 |

Power supply |

AC 220V 50Hz |

4 |

Power |

1.5kW |

5 |

Work environment requirements |

Temperature:0℃-50℃,No pollution and strong electromagnetic interference |

6 |

Gas source requirements |

0.5~1.0Mpa,Factory gas source,0.5-0.7Mpa,compressed air |

Equipment system technical parameters |

||

1 |

CCD detection method |

Feature point difference detection |

2 |

Effective detection range |

600mm*350mm (Customizable according to needs) |

3 |

Beat of 35s (15 seconds for feeding and conveying, 5 seconds for induction photography judgment, and 15 seconds for detection and conveying. The actual speed may be affected by factors such as manual feeding speed or abnormal confirmation and elimination) |

|

4 |

The camera installation height and focal length can be adjusted to adapt to different height battery cell groups |

|

Ⅵ、Main configuration:

Component |

Item |

Brand |

Mechanical part |

Guide rail |

HIWIN |

|

Bearing |

NSK |

|

Machining and sheet metal |

TMAX |

Electrical part |

Industrial computer |

Yanhong |

|

Source |

Mingwei |

|

Inductor |

AirTAC |

|

Control switch |

Chint |

|

Button |

Zerbo |

|

Indicator light |

Domestic |

|

Lens |

Yishen |

|

Light source |

Yishen |

|

Camera |

HIKVISION |

|

Visual control system/software |

TMAX |

Pneumatic system |

Pneumatic components |

Yadeke |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588