products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

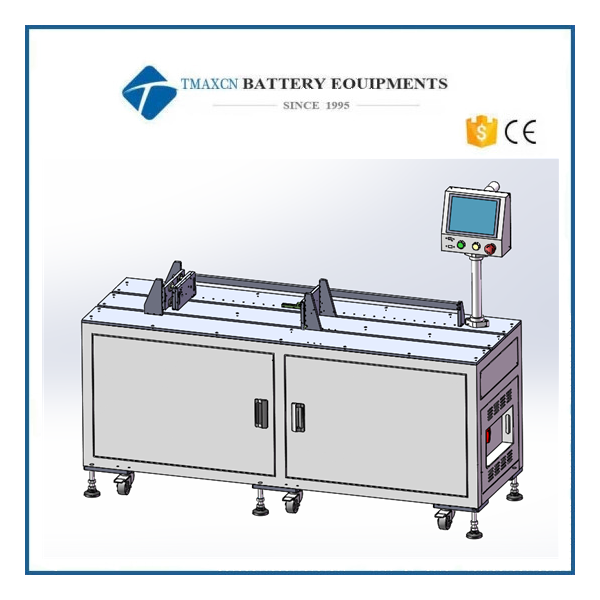

Prismatic Battery Stacking Pressing Machine

Model Number:

TMAX-ZW-FJ1000Type:

Semi-AutomaticDimension(L*W*H):

1570*500 *1400 mmCompliance:

CE CertifiedWarranty:

1 Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

30 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Prismatic Battery Stacking Pressing Machine

I.Equipment adaptation range

Prismatic Cell Lithium Battery.

II.Equipment Overview

The TMAX-ZW-FJ1000 prismatic battery stacking and pressing machine is suitable for stacking and forming square lithium batteries, as well as trapping them. It uses a servo motor, screw module, and planetary reducer for stacking and extrusion, and is controlled by a pressure controller. The extrusion stacking thrust can reach over 100KG, and the replacement is simple. It can timely control the stacking and extrusion stroke and stacking pressure, with triple protection functions of software limit, hardware limit, and pressure limit, It will not excessively squeeze the battery, and the squeezing accuracy is highly controllable.

III.Functional characteristics

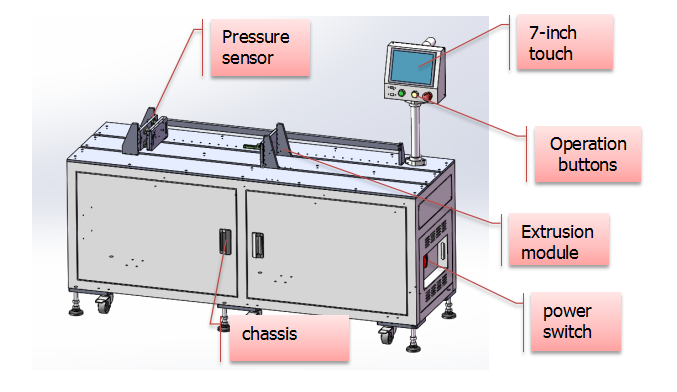

● 7 inch touch screen paired with PLC for control, easy to operate.

● Adapt to various types of batteries, can edit and set different parameters, and is easy to change and operate.

● Equipped with high-precision pressure sensors, the pressure accuracy is controlled within 0.1KG.

● Adopting screw module+servo motor+reducer for control, with large extrusion output force and high positioning accuracy

IV.Equipment structure

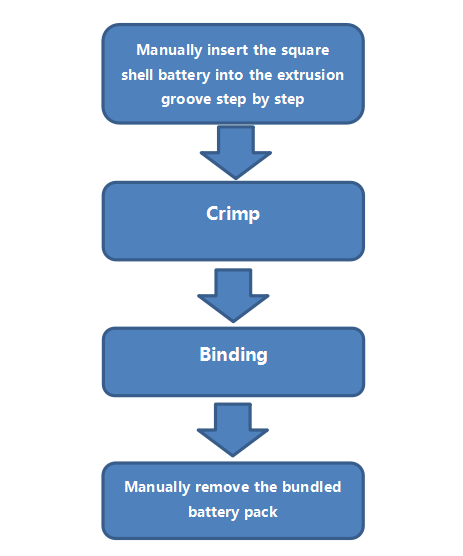

V.Workflow

VI.Technical Parameter

Equipment efficiency |

50 groups/hour (10PCS batteries) |

Equipment turnover rate |

≥98% |

Squeeze stroke |

1000mm |

Adapt to size range |

L:50~250mm; W:20~100mm; H:100~300 mm; |

Maximum stacking pressure |

100KG |

Pressure control error |

0.1KG |

control system |

PLC+touch screen |

Input power consumption |

1KW |

Input power supply |

AC220V/50HZ |

Compressed air source |

Not applicable |

touch screen |

7-inch touch screen |

Equipment appearance reference size |

L*W*H=1570*500*1400mm |

Overall weight |

300KG |

VII.List of Key Components

Key component names |

Brand |

Place of origin |

Lead screw |

TBI |

Taiwan |

Guide rail |

TBI |

Taiwan |

PLC |

Maintenance and control |

China |

touch screen |

Maintenance and control |

China |

servo motor |

Xinjie |

China |

drive |

Xinjie |

China |

source |

Jin Shengyang |

China |

Planetary reducer |

Zhuo Lan |

China |

Photoelectric sensor |

Huayifeng |

China |

Pressure sensor |

Chengying |

China |

VIII.Machine parameters:

8.1 Equipment power supply: two-phase~220V ± 10%/50Hz ± 10%

8.2 Overall power: 1000W

8.3 Equipment air pressure: None

8.4 Equipment weight: 300 KG;

8.5 External dimensions:L1570mm*W500mm*H1400mm;

8.6 Usage environment:

8.6.1 Please avoid using this equipment in places with high temperature, high humidity, vibration or impact, metal powder, and welding spatter. Pay attention to controlling the temperature of the surrounding environment of the equipment;

8.6.2 The equipment must be grounded and separated from the personnel grounding line;

8.7 Equipment service life: more than 5 years.

![]()

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588