products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Prismatic Lithium Battery Cell Stacking and Pressing Machine

Model Number:

TMAX-YLD—DDJY100SInput Power:

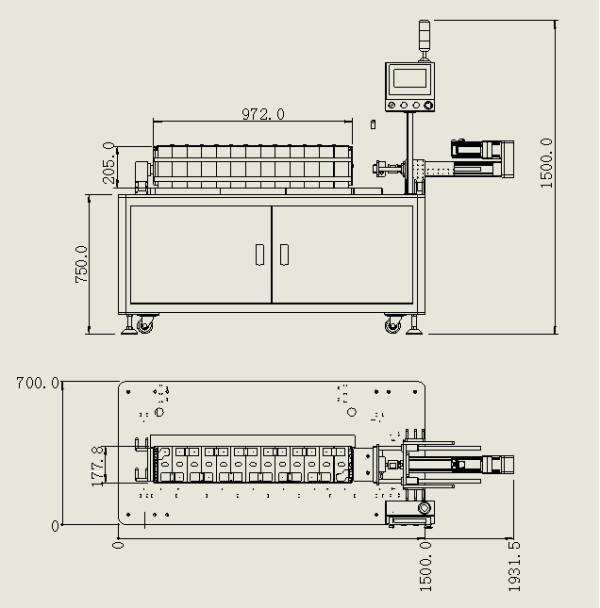

1.5KWDimension(L*W*H):

L1931mm*W750mm*H1500mmNet Weight:

180kgCompliance:

CE CertifiedWarranty:

One year limited warranty and lifetime supportPlace of Origin:

ChinaPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

30 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Prismatic Lithium Battery Cell Stacking and Pressing Machine

Ⅰ、Equipment Introduction:

Function Overview :

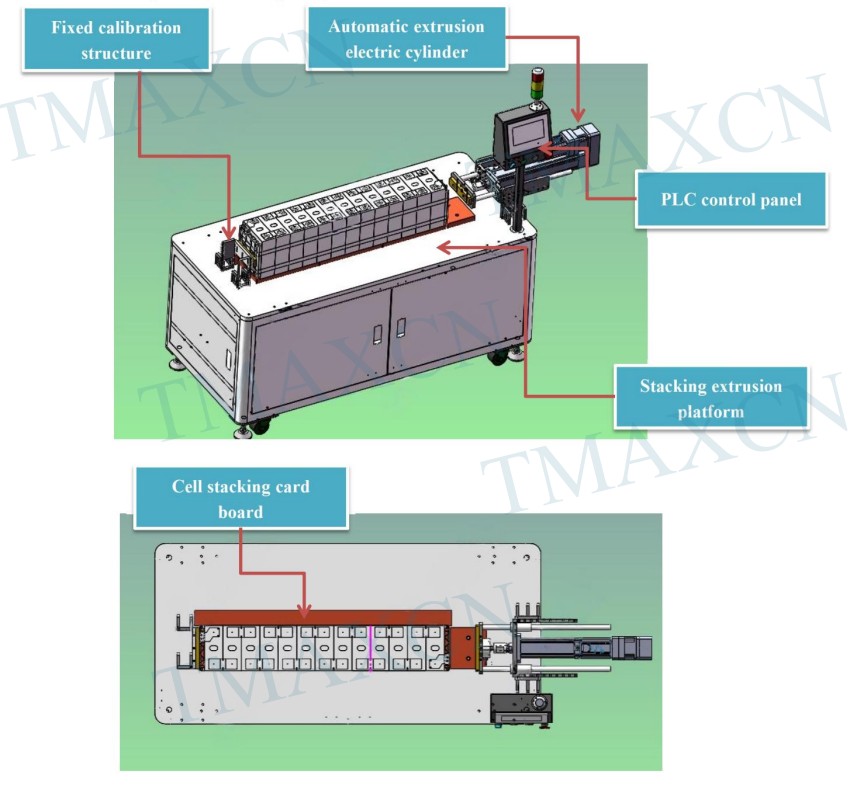

TMAX-YLD—DDJY100S Manually place the end plate, insulation board, and individual battery cells into the stacking platform in sequence. After stacking is completed, press the start button, and the PLC system controls the pressure sensor output signal. The electric cylinder automatically compresses and stops outputting when the thrust or travel distance reaches the set value. After the extrusion is completed, manually fix the plastic steel strip. After the fixation is completed, manually press the return button, and the electric cylinder will automatically reset.

2.11 Real time monitoring of extrusion distance and extrusion pressure dual protection, each parameter can be adjusted through PLC;

3.9 Equipment noise≤80db

4.4 Total power: ≤1.5KW

Ⅴ、Machine external dimensions and specifications :

The stacking and pressing equipment consists of a stacking extrusion platform, an automatic extrusion electric cylinder, a PLC system, and other structures:

Ⅶ、Machine related configuration :

Item |

Composition |

Brand |

Remark |

Main machine |

Cabinet body |

TMAX |

Lower sheet metal and upper profile/computer white |

|

Host countertop |

TMAX |

20mm steel plate |

Electrical system |

Servo electric cylinder motor |

TouchWin |

|

|

Pressure load gauge |

Ocean |

|

|

PLC |

TouchWin |

|

|

Touch screen

|

TouchWin |

|

|

Standard components |

Yiheda |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588