products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

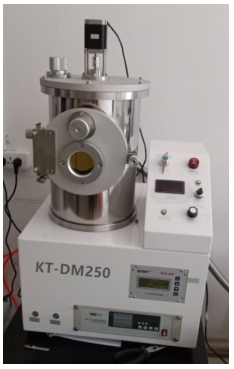

Water Cooling Circulation System Vacuum Coating Coater Machine Optional Mechanical Pump or Molecular Pump

Model Number:

TMAX-KT-DM250Compliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPlace of Origin:

ChinaShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Touch Screen Type Vacuum Hot Compression Sealing Machine with Special Aluminum Heating Plate for Perovskite SynthesisNext:

Lab 30ML Cartridge Dispensing Type Automatic Dispensing Machine with Diverse Movable Graphic Trajectory

Water Cooling Circulation System Vacuum Coating Coater Machine Optional Mechanical Pump or Molecular Pump

Use:

KT-DM250 coating instrument is developed by our company for optical film, organic film and metal film. Especially suitable for universities, high-tech enterprises, scientific research institutes and other metal electrode coating for film layer research and devices, currently in the domestic testing laboratory, perovskite solar cell field and other applications.

Main technical parameters:

1. Vacuum chamber: ∅250mm*H400mm (standard 400mm high, if the LIFT-OFF process chamber is required, make it to 500);

2. Maximum plating workpiece diameter: 3-4 inches, with a pull-out sample table, the sample can be rotated; Also equipped with copper substrate sample table;

3. Limit vacuum: 5*10-1Pa (mechanical pump system), 8*10-5Pa (molecular pump system);

4. Pumping time: Atmospheric pressure ~6*10-4Pa less than 30min (molecular pump system);

5. Evaporation: Resistive evaporation electrode (1 pair)

6. Power: 2KW; Equipped with a digital display evaporation power supply.

7. Opening mode: Front door structure, easy to change wire and loading;

8. Vacuum system: Mechanical pump vacuum system (mechanical pump + molecular pump system optional);

9. Water cooling circulation system 0.5P;

Reference picture

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588