products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

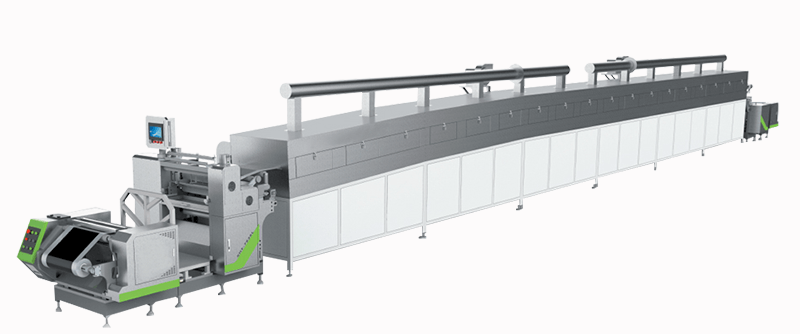

Precision Extrusion Single Side Slot Die Coating Machine for Battery Production Line

Model Number:

TMAX-XHPT-5063-MMCompliance:

CE CertifiedWarranty:

1 Year Limited Warranty With Lifetime SupportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

90 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Roll to Roll Slitting Machine for Lithium Battery Production LineNext:

High Precision Double Sides Extrusion Slot Die Coating Machine

Precision Extrusion Single Side Slot Die Coating Machine for Battery Production Line

1. Process Flow

The base material of the polar plate placed on the unwinding device enters the unwinding tension system after automatic correction, and enters the coating head after adjusting the unwinding tension. The polar plate is coated according to the setting procedure of the coating system. The coated wet electrode piece enters the oven and is dried by hot air. The tension of the dried pole piece is adjusted by the tension system, and the winding speed is controlled to synchronize with the coating speed. The pole piece is automatically rectified by the rectifying system to keep it in the set position, and is wound by the winding device.

2. Equipment Composition

1) Unwinding mechanism

2) Coating mechanism

3) Oven

4) Export rectifying mechanism

5) Discharge mechanism

6) Winder mechanism

7) Electrical control system

8) Precision feeding system

3. Main Parameter

NO. |

Project |

Parameter |

Remarks |

1 |

Normal Speed of Coating |

≤24m/min |

Normal coating speed is related to material system, coating thickness and solid content |

2 |

Coating Speed Accuracy Error |

≤0.1m/min |

|

3 |

Coating Width |

≤650mm |

|

4 |

Coating Length (Single Piece) |

≤2500mm |

|

5 |

Coating Machine Speed |

40m/min |

|

6 |

Overall Length of Coater |

≤43m |

It has a great relationship with configuration |

7 |

Equipment Air Pressure |

0.6~0.8 MPa |

Dry and free of impurities |

8 |

Single Side Coating Dry Thickness Error |

Li(NiCoMn)O2, LiFePO4, Cobalt±2μ (Mn±2μ) |

Edge, head and tail 8mm are excluded |

9 |

Double Side Coating Dry Thickness Error |

Li(NiCoMn)O2, LiFePO4, Cobalt±3.0μm (Mn±3μ) |

|

10 |

Single Side Weight Error in Single Chip |

±1.5% |

Measurement method (Fig. B) |

11 |

Minimum Coating Length |

20mm |

|

12 |

Minimum Length Dimension of Single Pole Piece |

50mm |

(One coating plus gap) |

13 |

Minimum Length Dimension of Single Double Segment Pole Piece |

100mm |

(Two coatings plus gap) |

14 |

Single Side Thickness Error of Electrode Head and Tail |

-10μm~ +5μm |

|

15 |

Interval Coating Minimum Gap |

10mm |

With the coating speed, the faster the speed, the greater the minimum gap. |

16 |

Accuracy Error of Coating Length |

±1.0 mm |

Within 3000mm |

17 |

Overlap Error of Front and Back Coating |

±0.5 mm |

|

18 |

Overlap Error of Front and Back Coating Edge |

±0.5 mm |

|

19 |

Edge Uniformity Error of Winding |

± 1 mm (start calculation after 5 turns) |

Φ 500mm roll |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588