products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

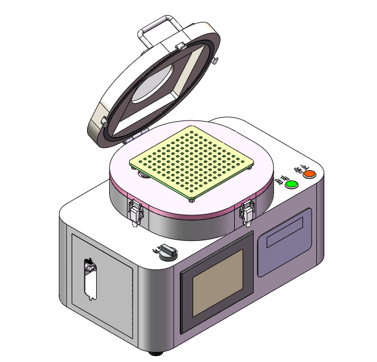

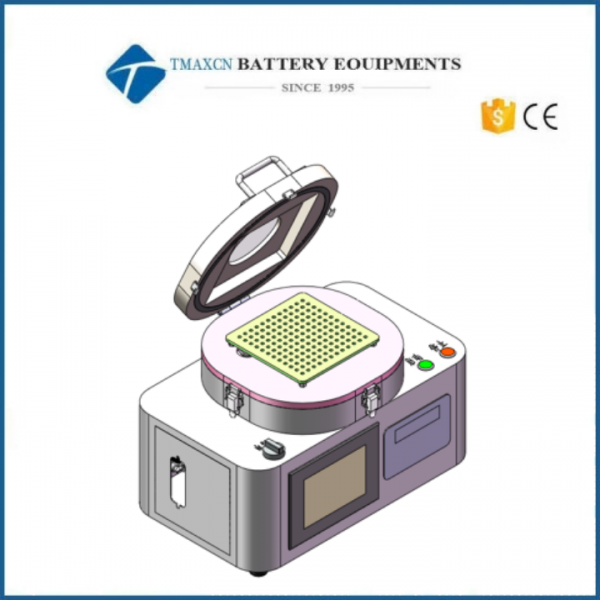

Desktop High Stability Small Vacuum Dryer Used for Perovskite Batteries

Model Number:

TMAX-KT-CM150Compliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPlace of Origin:

ChinaShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab 30ML Cartridge Dispensing Type Automatic Dispensing Machine with Diverse Movable Graphic TrajectoryNext:

Automatic Coating Vacuum Adsorption Coater Machine Using in Perovskite Films

Desktop High Stability Small Vacuum Dryer Used for Perovskite Batteries

Product introduction

KT-CM150 vacuum dryer is a small desktop device, working principle: accelerate solvent volatilization under rapid vacuum pressure, assist the physical process of film crystallization, rapid vacuum drying of various substrate coating materials. The advantages are good film uniformity, rapid solvent volatilization, high stability, and can be applied to the auxiliary film forming process of perovskite batteries after coating.

Product characteristics

a. Vacuum chamber: 304 stainless steel is used as the chamber to increase the safety and reliability of the chamber, and the cavity cover is left with a window to facilitate the observation of the film forming process; The sealing ring is sealed with fluorine glue to improve the sealing of the chamber.

b. Vacuum system: High power mechanical pump pumping rate can reach 40-60m3/h, the ultimate pressure can reach 5*10-1Pa.

c. Equipment size: The equipment covers a small area, can be placed on the desktop or glove box (KF40 interface), suitable for laboratory use, easy to operate.

Technical parameter

Cavity material |

304 stainless steel |

Equipment size |

About 500*300*400mm |

Applicable substrate size |

150*150mm |

Substrate thickness |

1-30mm |

Limiting vacuum |

≤5*10-1Pa |

Vacuum time |

10 seconds to 5pa, 20 seconds to 3pa |

Working power supply |

380V |

Equipment weight |

About 40kg |

Vacuum pump brand |

Custom |

Vacuum pump weight |

63Kg |

Vacuum pump |

Voltage and power 380V/1.1kW |

Vacuum pump pumping speed |

40-60m³/h |

Measuring range of vacuum gauge |

1.0×10-5-1.0×10-1Pa |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588