products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

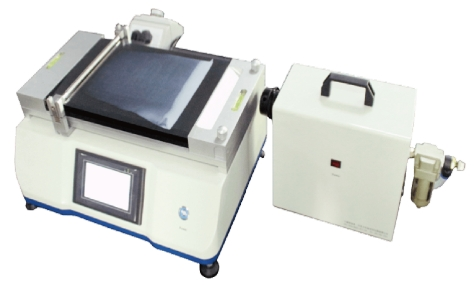

Automatic Coating Vacuum Adsorption Coater Machine Using in Perovskite Films

Model Number:

TMAX-KT-200BCompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPlace of Origin:

ChinaShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Desktop High Stability Small Vacuum Dryer Used for Perovskite BatteriesNext:

Lab 600W Pumping Speed Controllable Vacuum Dryer Equipped with Movable Tyre

Automatic Coating Vacuum Adsorption Coater Machine Using in Perovskite Films

Product description

The KT-200B vacuum adsorption coating machine is used to prepare uniform traceable coating films (manual coating films are often not coordinated, especially between different operators, which makes the comparison of samples difficult and even unreliable), and its reproducibility is good. Because the factors that affect the coating are the shear rate and the weight added to the construction tool. The instrument uses a precisely controlled wire rod or film applicator that moves back and forth at a selected speed. Because the test paper is smoothly adsorbed on the sucker and the shear rate and weight applied to the construction tool remain unchanged, the reproducibility of the coating is greatly improved.

Product characteristics

KT-200B vacuum adsorption coater is an automatic coating machine that integrates the technology of similar foreign products. Compared with other domestic products, it has the following characteristics:

1) Wide range stepless speed regulation: 10~999mm/min

2) High precision linear guide rod + DC brushless motor, making the coating speed more stable

3) The vacuum pump is external, avoiding the jitter caused by the traditional machine (vacuum pump built-in) structure when coating film.

4) Carefully designed coated bracket, more simple and convenient operation, and can arbitrarily increase the support load to adapt to the flexible test plate

5) High hardness, high flatness (the entire platform error is less than 5 microns) aluminum oxidation vacuum suction platform

6) Vacuum suction platform optimization design, the adsorption force distribution is highly uniform

7) Set the starting point of the coating at will to adapt to different sizes of substrates.

8) Four kinds of coating distance can be selected

9) Optional wire rod, adjustable doctor blade and other coating tools (total length 240mm)

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588