products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

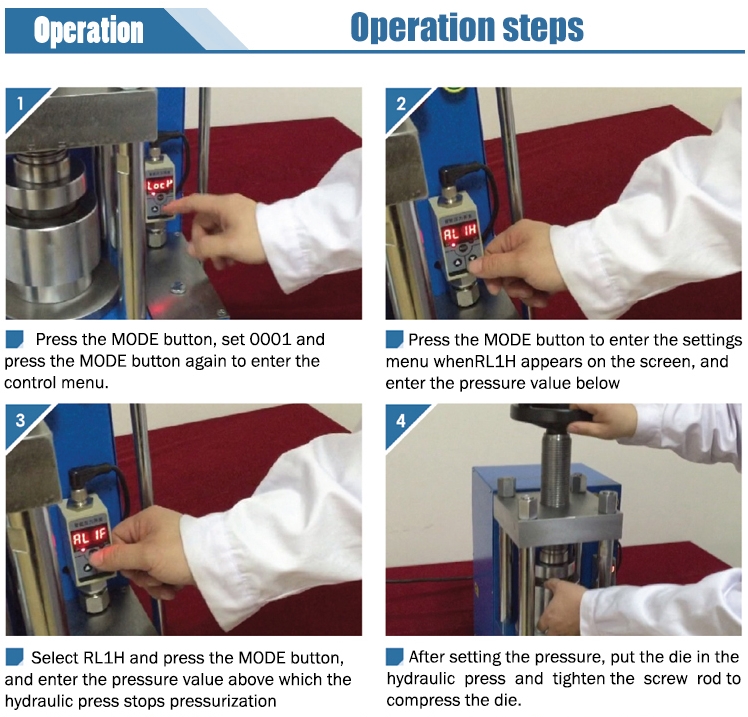

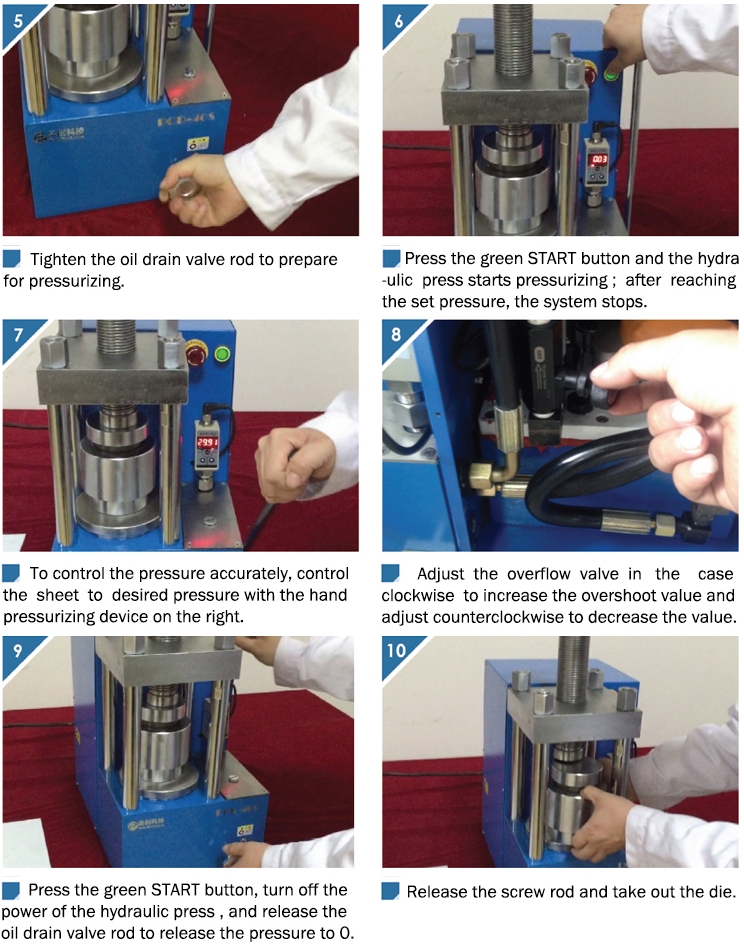

20T to 60T Lab Smart-electric Hydraulic Powder Tablet Press Machine with Digital Pressure Sensor

Model Number:

TMAX-DYPCompliance:

CE CertifiedWarranty:

1 yearPlace of Origin:

China (Mainland)Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab Cemented Carbide Cold Press Molds Set for Hydraulic PressNext:

Intelligent Electric Automatic Isostatic Compact Cold Pressing machine 20T 40T 60T 100T

20T to 60T Lab Smart-electric Hydraulic Powder Tablet Press Machine with Digital Pressure Sensor

Features

New DYP-TS digital display series

DYP-TS series electric tablet press has two methods of electric and manual pressure. It is popular with users because of its beautiful appearance, fast boosting and convenient operation. The use of electric pressure and manual supplementary pressure can accurately control the pressure of the hydraulic press. It is widely used for pressing powder samples into various test pieces for dry scientific research and analysis, and can also be used as a common press.

The machine adopts digital pressure sensor, which is more accurate than pointer pressure gauge. When the output pressure value of the tablet press is lower than the lower limit of the set value, the machine will automatically start to supplement the pressure, which can realize the automatic pressure maintenance function for a long time.

Technical Parameter

Equipment model |

DYP-20TS |

DYP-30TS |

DYP-40TS |

DYP-60TFS |

Pressure range |

1-20T (0-28MPa) |

1-30T (0-31.5MPa) |

1-40T (0-30MPa) |

1-60T (0-34MPa) |

Pressure conversion |

1T=1.4Mpa |

1T=1.05Mpa |

1T=0.75Mpa |

1T=0.56Mpa |

Piston diameter |

Dia95mmchrome cylinder |

Dia110mm chrome cylinder |

Dia130mm chrome cylinder |

Dia150mm chrome cylinder |

Maximum piston stroke |

30mm |

40mm |

50mm |

50mm |

Pressure gauge type |

XNNETS "S" electric digital display meter, range 0.0-40.0Mpa, accuracy 0.1Mpa |

|||

Pressure stability |

<1MPa/10min |

|||

Pressurization method |

Electric pressurization/manual slow pressurization |

|||

Pressure Compensation method |

Automatic pressure compensation / Manual pressure compensation |

|||

Overall structure |

One-piece structure, no sealing connection of equipment, reducing oil leakage points |

|||

Equipment power supply |

220V (50Hz/60Hz) |

|||

Safety protection device |

none |

none |

none |

plexiglass protective cover |

Table diameter |

105mm, |

120mm |

140mm |

160mm |

Working space |

width 80×150mm |

width 92×160mm |

width115×185mm |

width185×250mm |

Overall dimension |

245×415×415mm |

275×430×420mm |

295×450×500mm |

405×470×565mm |

Equipment weight |

58kg |

72kg |

92kg |

140kg |

Model description |

1 hydraulic press, mold optional. Four columns, can be customized to increase height, can add "F" plexiglass protection device |

|||

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588