products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Lab Cemented Carbide Cold Press Molds Set for Hydraulic Press

Model Number:

TMAX-MJY-PCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

12T Laboratory Electric Isostatic PressNext:

20T to 60T Lab Smart-electric Hydraulic Powder Tablet Press Machine with Digital Pressure Sensor

Lab Cemented Carbide Cold Press Molds Set for Hydraulic Press

Features

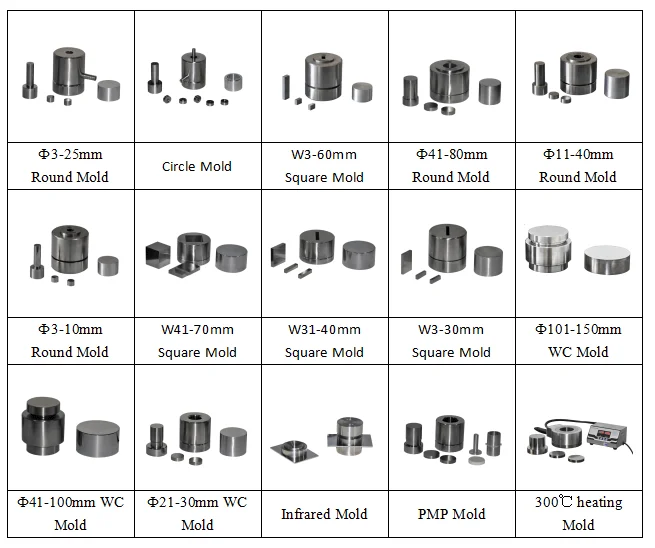

Cylindrical Die

1. Cylindrical die is a common powder pressure molding tool in the laboratory, which can press powder materials into various solid test pieces, which are widely used in superconductivity, batteries, cement, ceramics, rare earth, catalysis, silicate, powder Metallurgy, sea mud analysis and other new material research and development fields.

2. Die material: high-speed steel (ASSAB+17) or alloy tool steel (Crl2MoV) imported from Japan, and cemented carbide (YT15) can also be customized.

3. Commonly used specifications are generally within Dia2mm-Dia40mm, and other specifications and sizes can be customized.

Calculation formula of die pressure: area of oil cylinder / area of die (mm2) x value of pressure gauge = pressure of die (MPA)

Tonnage (T) × 9800n / die area (mm2) = die bearing pressure (MPA)

Warning: the normal pressure range of the mold is less than 800MPa, the overpressure is less than 1000MPa, and the damage is less than 1500MPa

Square Die

1. Square die is suitable for some easy-to-form powder samples, and various shapes, specifications and materials can be customized! Such as squares, strips, triangles, polygons, arcs and special shapes. Commonly used specifications are generally within 100mm × 100mm, and other specifications and sizes can be customized.

Carbide Die

1. Carbide die(YT15), also known as aluminum carbide mold or bustard steel mold, is a metal carbide alloy material with high hardness and wear resistance, suitable for pressure forming of some hard powder samples, and the commonly used specifications generally do not exceed 40mm .

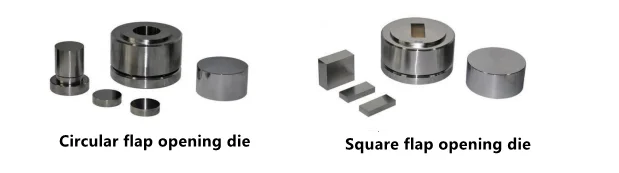

Flap Opening Die

1. Flap opening die is also called easy-extraction combined mold. Generally, 3-4 inner cores are combined into a set of cavities. The inner core is covered by a sleeve from top to bottom and fixed as a whole. There is no need to remove the film, mainly for some ultra-fine powder or powder samples that are not easy to form and have a high demand for samples.

2. Flap opening die type: cylindrical, rectangular, etc., the commonly used size is generally not more than 100 × 100mm.

Hot Pressing Die

1. The hot-pressing die is usually composed of a temperature controller and a heating mold, which has the advantages of small size, heating block, and accurate temperature control. The chemical stability of sample particles or powder changes after hot pressing, which is an ideal supporting equipment for advanced engineering and technical personnel to perform spectral detection, analysis and qualitative analysis.

2. Hot pressing mold type: cylindrical, rectangular, double flat, infrared quantitative, etc., the common temperature is ≤300°C or ≤500°C.

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588