products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

100T Automatic Lab Hydraulic Press with Plexiglass Doorsheet Steel Protection

Model Number:

TMAX-ZYP-100TZCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

100T Electric Powder Tablet Press with Holding Time 0-999.59 MinutesNext:

65T Electric Powder Tablet Press with 4.3 Inch LCD Screen

100T Automatic Lab Hydraulic Press with Plexiglass Doorsheet Steel Protection

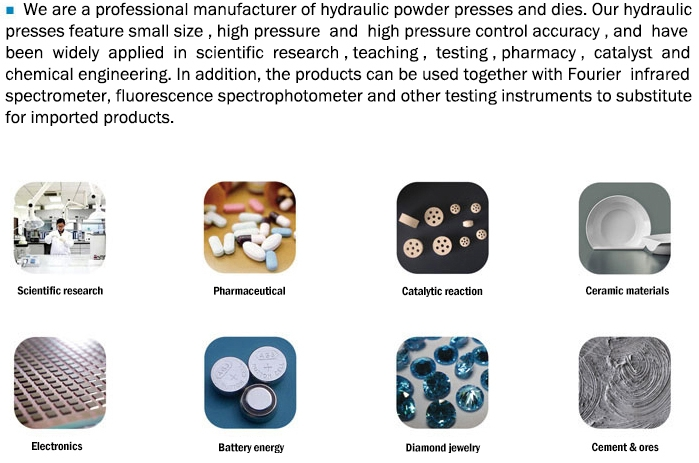

Application field

Advantages of metal button (service life > 100,000 times)

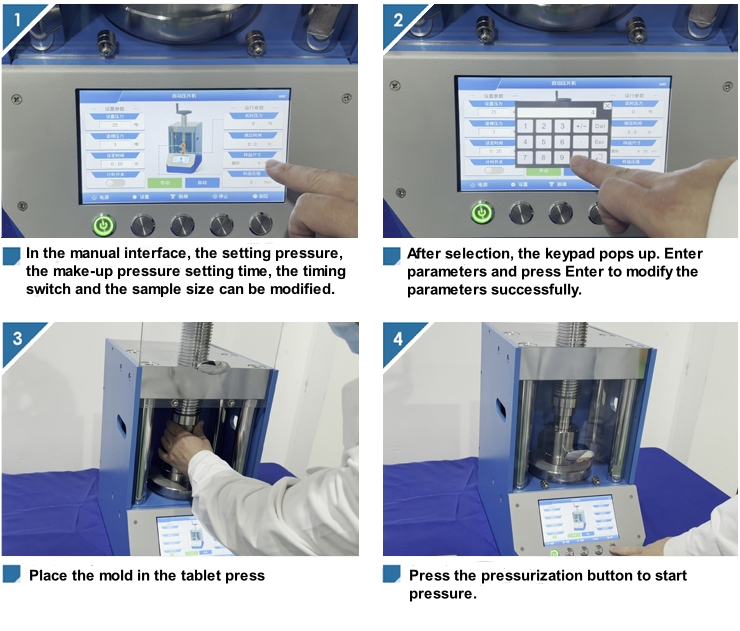

Operation interface (Manual mode)

Standard interface: you can set various parameters, pressure, die withdrawal, time, sample size, etc., in this interface alone

Pressurization button: Press according to the parameters set on the interface.

Stop button: Press the stop button during the pressurization process to stop the pressurization.

Demoulding button: Press the demoulding button to release the sample according to the demoulding pressure.

Timing switch: The timing function can be turned on and off.

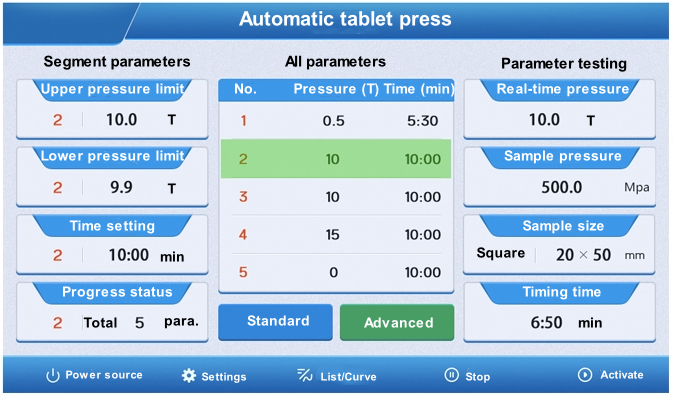

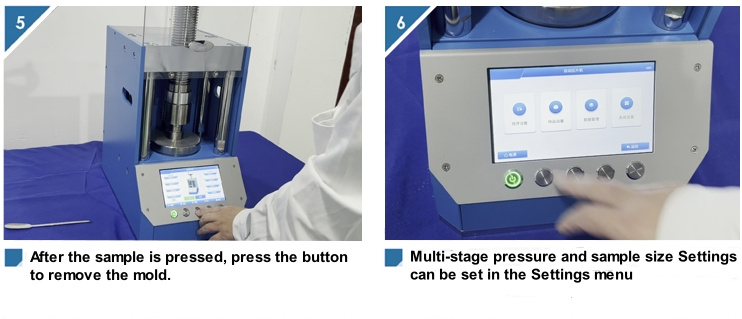

Operation interface (Automatic mode)

Activate button: Can be pressed according to the multi-stage pressurization program.

Stop button: During the pressurization process, you can stop the pressurization process.

List/Curve: The current display state can be switched between list and curve

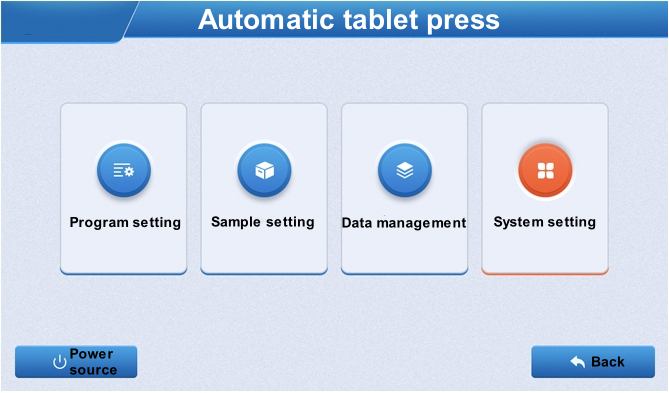

Setting interface

Tap Settings on the operation screen to enter the Settings screen. The Settings screen has four ICONS.

Program Settings: you can set up multiple pressure procedures and pressure holding time.

Sample setting: The shape and size of the sample can be set to facilitate the user to calculate the pressure of the sample.

Data management: Previously saved data records can be invoked and modified..

System Settings: Administrators can set various parameters, enter the password "666"

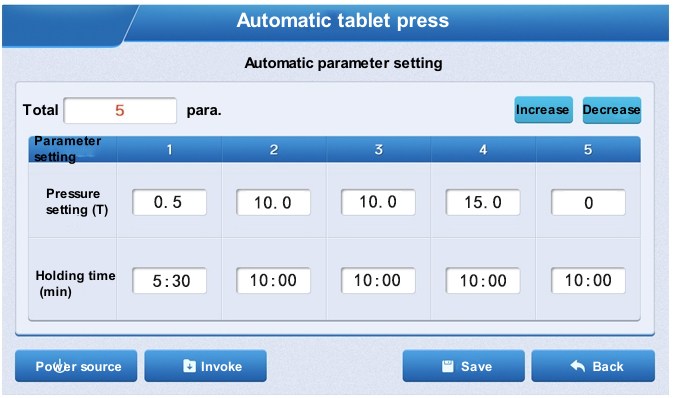

Setting interface

Multi-segment program Settings: Up to 5 segments of pressurized programs can be set.

Invoke button: Call the set parameters to the automatic operation interface for pressure.

Save button: Save the set parameters to the database for later invocation.

Back button: Returns to the Settings screen

Operation procedure

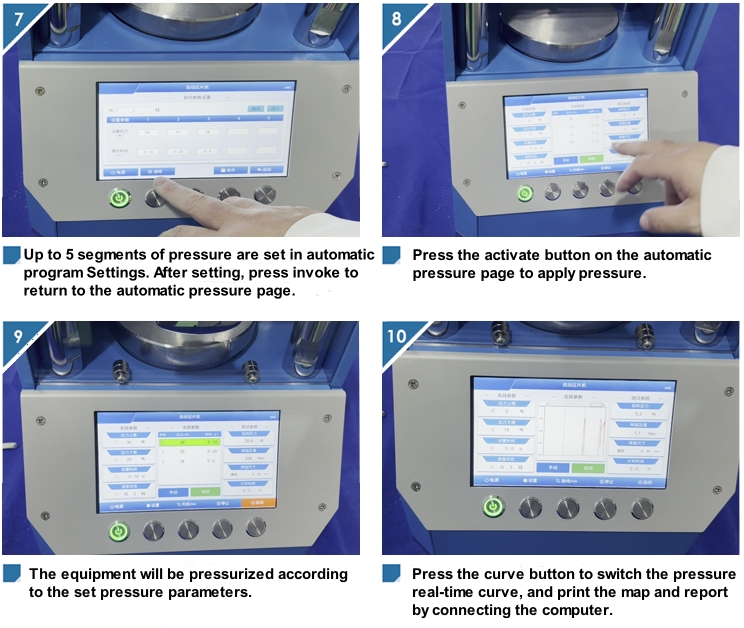

Technical parameter

Instrument type |

PP-100S |

Pressure range |

0-100.0 tons |

Pressurization process |

Common or connected multi-section pressure and can display pressure curves |

Holding time |

1 s to ∞ s |

Pressure conversion |

Program automatically converts mold pressure |

Liquid crystal display |

7 inch (IPS HD) touch screen |

Metal keying |

Silver-plated contact, service life > 100,000 times |

Equipment protection |

Steel plate protection with plexiglass doors |

Limit switch |

Automatic pressure relief when the cylinder reaches the limit height |

Remote control |

Optional computer for remote control and print reports |

Cylinder stroke |

50mm(T) |

Space size |

185x250mm(MXN) |

Overall dimension |

330X580X620mm(LxWXH) |

Equipment power supply |

1500W(220V/110 can be customized) |

Equipment weight |

240Kg |

Powder tablet press size diagram |

|

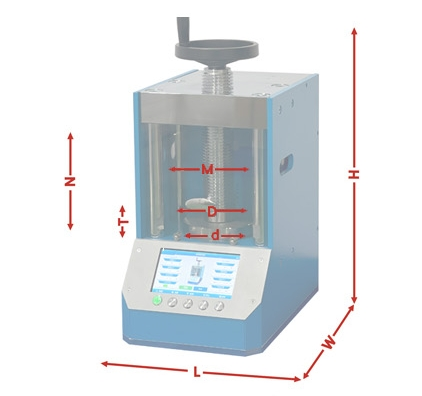

Pressure conversion

Actual pressure |

System pressure |

Double display pressure gauge |

0.2[Tons] |

1.25[MPa] |

|

0.4[Tons] |

2.51[MPa] |

|

0.6[Tons] |

3.77[MPa] |

|

0.8[Tons] |

5.03[MPa] |

|

1[Tons] |

6.28[MPa] |

|

2[Tons] |

12.5[MPa] |

|

3[Tons] |

18.8[MPa] |

|

4[Tons] |

25.1[MPa] |

|

5[Tons] |

31.4[MPa] |

It is suggested that the general system pressure should not exceed 35MPa, otherwise it will affect the service life of the equipment.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588