products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

2021-07-07

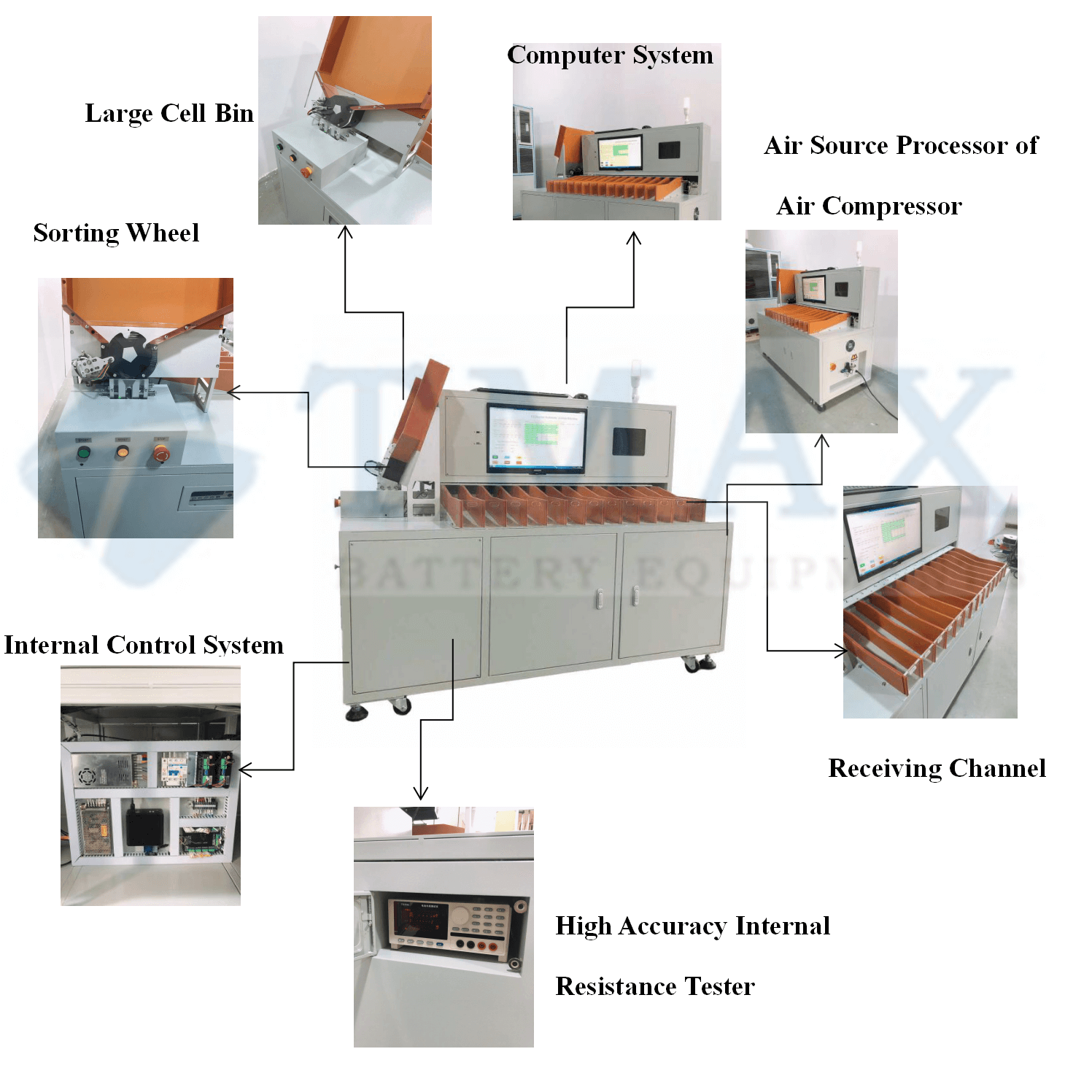

Lithium battery sorting machine is closely related to lithium batteries, which plays a very important role. First of all, in our daily life, we often need to use lithium battery products. For example, the lithium battery electric bicycle that we often use at work is a good example, in which the lithium battery automatic bicycle accounts for 70% of the daily traffic work. A whole battery pack provides power and energy in a lithium battery bicycle. Secondly, how to determine that the whole battery pack is complete, unified and safe? This is the role of lithium battery sorter. The sorter obtains the data of each cell through internal resistance, voltage and internal pressure, so as to achieve the data of each cell. Only in this way can the lithium battery pack produced be safe and durable.

Internal resistance test of lithium battery: it refers to the resistance of current flowing through the battery when the battery is working. It is generally divided into AC internal resistance and DC internal resistance. Because the internal resistance of rechargeable battery is very small, when measuring DC internal resistance, the polarization internal resistance is generated due to the polarization of electrode capacity, so its real value can not be measured. However, measuring AC internal resistance can avoid the influence of polarization internal resistance and obtain the real internal value.

Test lithium battery voltage: refers to the potential difference between the positive and negative poles of the battery when the lithium battery is connected to the load, that is, when there is current flowing through the circuit, also known as discharge voltage. Because of the existence of ohmic resistance and polarization overpotential, the working voltage of lithium battery is lower than the open circuit voltage.

Testing the internal pressure of lithium battery: it refers to the pressure formed by the gas generated during the charging and discharging process of lithium battery, which is mainly affected by the battery material manufacturing process, structure and other use process factors. Generally, the internal pressure of the battery is maintained at a normal level, and the internal pressure of the battery may rise in the case of overcharge or overdischarge.

In short, the lithium battery sorter is a part of the lithium battery assembly equipment to inspect the lithium battery. Its steps are to ensure that each cell has the same value. In this way, the lithium batteries with the same value are welded into a lithium battery pack. After installing the protection plate, it is basically a finished product, which can be directly installed on the electric bicycle.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588