products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Small Tonnage 300C or 500C Integrated Manual Hot Press with 120x120mm Double Heating Plate

Model Number:

TMAX-PC-600BCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

IPS HD Touch Screen 30T Automatic Fluorescent Tablet PressNext:

Lab 60T Automatic Fluorescent Tablet Press with 7-inch Touch Screen

Small Tonnage 300C or 500C Integrated Manual Hot Press with 120x120mm Double Heating Plate

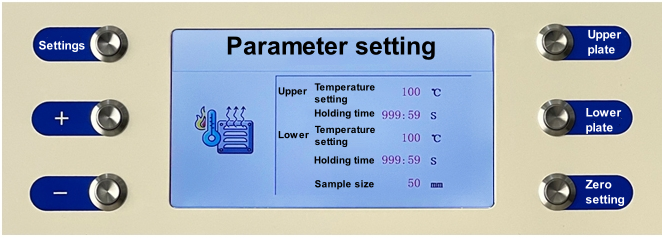

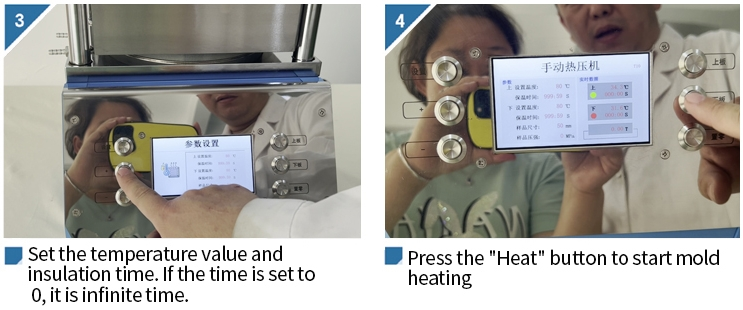

Setting interface

Settings

Under the operation interface, press the setting button to enter the setting interface, press the setting button again, move the setting content, move to the mold diameter, press the setting button again to return to the operation interface. Note: When the time is set to "0", the setting time is infinite.

+

On the operation screen, press the + key to add the number.

-

On the operation screen, press _ to reduce the number of Settings.

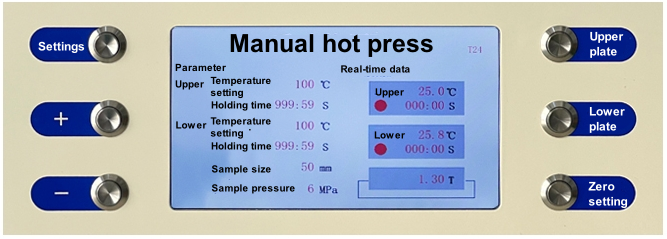

Operating interface

Upper plate

Press the "Upper plate" button in the operation interface, and when the upper heating plate starts to heat to the set temperature, the timer starts to record the time and starts to maintain the constant temperature. When the timer is over, stop the heat. Or press the "Upper plate" button again to stop heating the upper heating plate. During the heating process, all setting buttons are invalid.

Lower plate

Press the "Lower plate" button in the operation interface, and after the lower heating plate starts to heat to the set temperature, the timer starts to record the time and starts to maintain the constant temperature. When the timer is over, stop the heat. Or press the "Lower plate" button again to stop heating the Lower heating plate. During the heating process, all setting buttons are invalid.

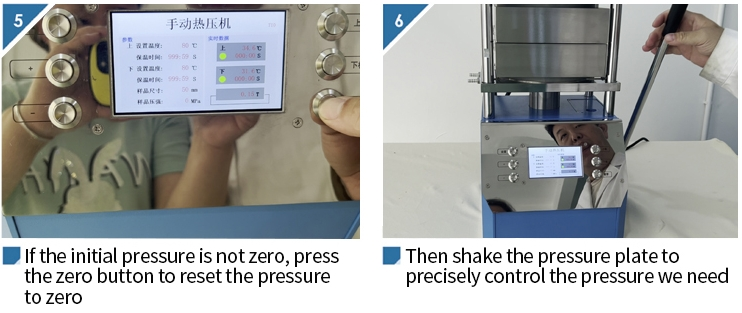

Zero setting

If the sample is not in contact, but the device has shown pressure, it may be the weight of the heating plate, we can press the "zero" button to clear the pressure. To make our samples more accurate.

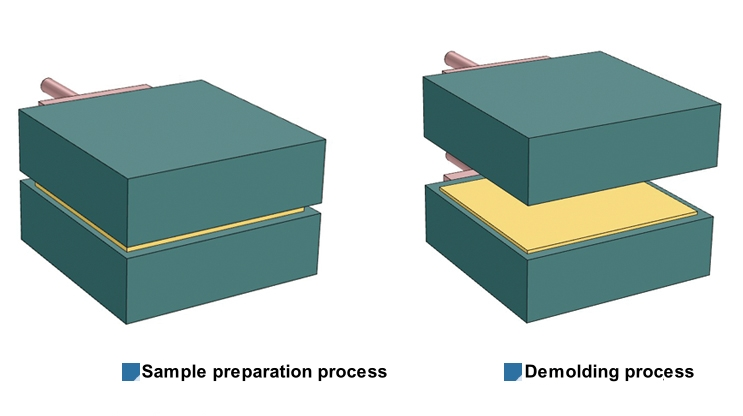

Mold operation diagram

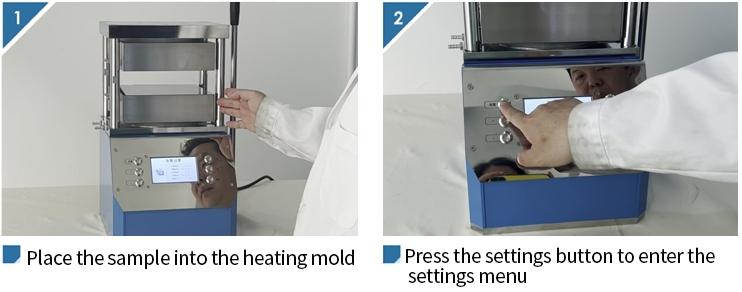

Operation procedure

Technical parameter

Instrument type |

PC-600B(300.0℃)/PC-600BG(500.0℃) |

Pressure range |

0-5.0 tons |

Piston diameter |

Chrome plated cylinder Φ50mm(d) |

Overall structure of subject |

The equipment has no sealed connection to reduce oil leakage points |

Mold heating temperature |

Room temperature -300.0℃/500.0℃ |

Constant temperature time |

1 s to ∞ s |

Temperature control accuracy |

0.1 ℃ |

Heat insulation method |

Imported heat shield |

Cooling method |

|

Mold size |

Double plate heating 120x120mm(MXN) with lead screw |

Work space |

140x140x130 mm |

Overall size |

250x230x390 mm(LxWXH) |

Power source |

700 W(220V/110V can be customized) |

Main engine weight |

58 Kg |

Powder tablet press size diagram |

|

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588