products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Fine Grinding Equipment Roller Ball Mill

Fine Grinding Equipment Roller Ball Mill

-

Roller Diameter 200mm, Hydraulic Three Roller Mill Suit for Various Viscosity Material

Roller Diameter 200mm, Hydraulic Three Roller Mill Suit for Various Viscosity Material

DYS Hydraulic three roller mill is a new product which suit for various viscosity material. The cooling effect of this series of machine is triple or more than traditional hydraulic three roller mill, it can make the speed of operation higher, and the maximum speed can reach 800 rpm or more, so that this machine can meet the high shear forces, as well as demand for high productivity. The roller is driven by hydraulic system, and the gap adjustment device with high precision can be customized. This machine adopts PLC man-machine interface control system, which can remotely connect with the ERP. Optional Ball and Jar 1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank. 2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20 Working principle: TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

-

Roller Diameter 400mm, Hydraulic Superfine Five Roller Mill for for Pulp Refining, Dispersion and Grinding

Roller Diameter 400mm, Hydraulic Superfine Five Roller Mill for for Pulp Refining, Dispersion and Grinding

Hydraulic five roller mill is new-designed equipment for pulp refining, dispersion and grinding. Material are fed between the first and second roll and discharged from the fifth roll after passing several rolls. Tilting arrangement of the rolls make the machine have more internal space. Hydraulic system of the rolls adopt “floating roller system”which is a quite mature technology of our company. Customized PLC touch screen promotes the automation level of equipment, and also the data, formula can be stored as parameters.

-

Roller Diameter 150mm 260mm and 405mm, Three Roller Mill for Grinding the Material with High Dispersive Viscosity and Fine Size

Roller Diameter 150mm 260mm and 405mm, Three Roller Mill for Grinding the Material with High Dispersive Viscosity and Fine Size

Three roller mill is welded by high quality steel plate. The transmission gear adapts oil-immersed type and the operative hand-wheel is transmitted by gear. It features beautiful appearance, convenient to operate, long life and so on. Particularly it is suitable for grinding the material with high dispersive viscosity and fine size.

-

Roller Diameter 50mm 80mm 120mm, Superfine Precise Three Roller Mill for Nano New Material, Metal Paste, Ceramic Slurry, Electronic Slurry, Cosmetics

Roller Diameter 50mm 80mm 120mm, Superfine Precise Three Roller Mill for Nano New Material, Metal Paste, Ceramic Slurry, Electronic Slurry, Cosmetics

Longxin superfine series are high performance three roller mill, which created for hyper precise, narrow particle size distribution. It has an unparalleled reproducibility in nano grinding, which is best choice for Nano new material, Metal paste, ceramic slurry, electronic slurry, cosmetics.

-

Roller Diameter 50mm 80mm and 120mm, Superfine Precise Three Roller Mill for Accurate Dispersion Control and Production of Fine Particles

Roller Diameter 50mm 80mm and 120mm, Superfine Precise Three Roller Mill for Accurate Dispersion Control and Production of Fine Particles

Roller mill iis designed for manufacture who wanna achieve accurate dispersion control and production of fine particles. It supply customers effective and extremely accurate means of reducing particle size and dispersion, with significant reproducibility. As far as product R&D, small scale production and the establishment of small production lines. DS type three roller mill can provide flexible, precise control to meet your requirements, and process parameters will provide a rigorous technical basis for the expansion of reproduction.

-

Roller Diameter 260 and 400mm, Hydraulic Three Roller Mill Controlled by Hydraulic Pressure from Double-impeller Pump

Roller Diameter 260 and 400mm, Hydraulic Three Roller Mill Controlled by Hydraulic Pressure from Double-impeller Pump

Three roller mill controlled by hydraulic pressure from double-impeller pump. The basic work of machine such as feeding, discharging and size of material is controlled by hydraulic pressure. It features high automatization content, convenient to operate and safe in use. Because the hydraulic system adapts plate type structure, its arrangement is more reasonable. The roller is cast by special alloy, its strength is high and its surface has high hardness and wear resistance property. It is an ideal equipment to grind high quality paste material.

-

Roller Diameter 150mm 260mm 315mm and 400mm, Flat Hydraulic Three Roller Mill with PLC Automatic Control Used in All Kinds of Oil, Electronic Paste, Plant Gum , Soap, etc

Roller Diameter 150mm 260mm 315mm and 400mm, Flat Hydraulic Three Roller Mill with PLC Automatic Control Used in All Kinds of Oil, Electronic Paste, Plant Gum , Soap, etc

Flat hydraulic three roller mill series use special grade alloy steel, which could reach unbelievable hardness. This series will use proportional valve adjusting the roller pressure&gap, thus the whole machine will be more stable and have longer life. This machine could be PLC automatic control.

-

Roller Diameter 150mm 230/260mm 305mm 400mm, Three Roller Mill Machine with A Speed Reducer Gear Box

Roller Diameter 150mm 230/260mm 305mm 400mm, Three Roller Mill Machine with A Speed Reducer Gear Box

Roller mill is welded by high quality steel plate. The transmission gear adapts oil-immersed type and the operative handwheel is transmitted by gear. It features beautiful appearance, convenient to operate, long life and so on. Particularly it is suitable for grinding the material with high dispersive viscosity and fine size. JRS series Three Roller Mill machine widely used in pencil leads, colorant, which need very strong force. The machine with a speed reducer gear box.

-

Hydraulic Two Roller Mill Machine with 400 Roller Diameter Widely Used for Food Stuff, Chocolate, Soap and Pharmaceutical, etc

Hydraulic Two Roller Mill Machine with 400 Roller Diameter Widely Used for Food Stuff, Chocolate, Soap and Pharmaceutical, etc

Two roller mill is designed specially for dispersing rough material and adjusting material for next procedure. It is widely used for dispersing and pre-dispersing all kinds off materials such as food stuff, chocolate, soap and pharmaceutical, etc.

-

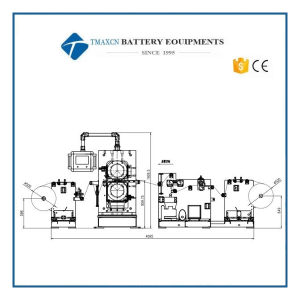

Hydraulic Electric Roll to Roll Press Machine for High-precision Rolling of Battery Electrode

Hydraulic Electric Roll to Roll Press Machine for High-precision Rolling of Battery Electrode

Roll Sublimation Heat Press Roller Machine For Li ion Battery Pole Piece Rolled

-

Battery Hot Calender Electrode Rolling Press Machine for Pilot Line

Battery Hot Calender Electrode Rolling Press Machine for Pilot Line

Battery Hot Battery Calender Electrode Rolling Press Machine for Pilot Line 1.Introduction 1.1 Function: This battery electrode sheet continuous rolling production line is used in the rolling process of lithium-ion battery pole piece production to realize the continuous rolling production of battery pole piece coils and meet the specifications and quality required by the battery pole piece process; 1.2 Equipment composition: It mainly includes unwinding device, belt connecting device, edge trimming device, dust removing and iron removing device, heating roller press, belt connecting device after pressing, winding device, hydraulic system, drive control system, disassembly roller device, etc; 1.3 Schematic diagram of equipment layout (the picture shows the right type, and the left type is symmetrical to it): 2.Process parameters 2.1 Application: Suitable for the rolling process of battery materials such as lithium iron phosphate, lithium cobalt oxide, lithium manganate, ternary, lithium titanate, etc. 2.2 Adapt to incoming material specifications: pole piece width 150~300mm, material roll diameter ≤500mm 2.3 Output product indicators: 2.3.1 Thickness uniformity of pole piece after rolling: ≤±0.002mm (required thickness accuracy of incoming material: ≤±0.002mm); 2.3.2 Alignment error of winding edge: ≤±0.3mm 3.Installation 3.1 The main engine part requires ground load ≥ 3.5t/㎡ (or base on the provided foundation drawing) 3.2 Power supply: 380V±5%, 50Hz three-phase five-wire system 3.3 Total power: 60kW+10% safety factor/unit 3.4 Compressed air: pressure 0.2~0.7MPa, flow rate: 20L/min, the outer diameter of the interface pipe is 8mm 3.5 Operating environment: temperature range 0~+45℃ relative humidity: ≤30% 3.6 The inner diameter of the barrel: 3inch, the length of the barrel ≤550mm 4. Equipment function index 4.1 Overall dimensions of the continuous rolling line (length*width*height): 4.8×2.6×2 m 4.2 Total weight of equipment: about 9 tons 4.3 Appearance color of the equipment: national standard warm gray 1C 4.4 Arrangement: left/right (the power drive part is on the left/right when viewed from the feed end) 4.5 Rolling speed: 1-12m/min 4.6 Maximum pressure between rollers: 1800kN 4.7 Overall equipment efficiency: OEE≥95% 4.7.1 Calculation formula: OEE = availability rate × performance × product qualification rate 4.7.2 Sub-indices Related sub-indices Note Availability = operating time ÷ planned working time 98% Utilization rate Expressiveness = total output ÷ (operating time min*CPM) 98% Equipment capacity Product qualification rate = actual number of good products ÷ planned number of good products 99% Note: When calculating, deduct the factors that affect normal production such as material supply, power supply, gas supply, etc. 4.8 Design and manufacturing regulations and standards: in line with relevant national standards 5.Main performance indicators 5.1 Unwinding device l Function: Passively provide pole pieces for rolling under certain tension control l Unwinding inflatable shaft: Φ74mm with inflatable gun l Effective use length of inflatable shaft: 550mm l Tension adjustment (setting) range: 1~20kgf l Tension control accuracy: 5% l Correction control: infrared photoelectric correction l Correction stroke: ±50mm l Edge control: deviation correction accuracy is ≤±0.2mm l Magnetic powder brake: 50Nm 5.2 Front connecting device l Function: Used to connect the pole piece when it breaks during the rolling process or when changing the material roll to reduce the waste of pole piece. l Composition: It is composed of connecting plate, pressure rod, air cylinder, guide roller and other parts. l Control: the cylinder is controlled by the manual pneumatic valve to compress and loosen the pole piece l Operation: manual connection 5.3 Edge trimming device l Function: Used to cut off the uncoated foil on both sides of the pole piece, reduce the wrinkles of the pole piece caused by the inconsistent elongation rate during rolling, and reduce the scrap rate caused by the pole piece strip. l Principle: The upper cutting blade is manually fed, relying on the knife, and the left and right cutting knives are controlled separately. l Drive: 0.55KW variable frequency motor drives the lower cutter shaft to be consistent with the rolling speed l Slitting speed: the slitting speed is synchronized with the rolling of the main machine l Upper cutting blade: Φ100×Φ65×1.2mm l Cutting blade: Φ100×Φ65×2mm 5.4 Dust removal device l Function: Clean up the dust and burrs on the pole piece l Composition: consists of front and rear roller brushes, air cylinders, vacuum cleaners, roller brush drive motors, etc. l Principle: Use front and rear roller brushes to brush down the dust and burrs on the pole pieces, pass the dust suction bucket, the dust and air are separated by the cyclone separator, and the clean air is discharged from the muffler through the fan. Clean the dust regularly. l Number of roller brushes: 2 l Drive: 0.75KW high pressure fan drive l Processing air volume: 2.4 m3/min 5.5 Front damping device l Function: reduce the jitter of the pole piece during the rolling process and prevent the strip from breaking l Composition: fixed guide roller, floating guide roller, fixed bracket, etc. l Principle: The pole piece passes through the floating guide roller to reduce the jitter of the pole piece and prevent the pole piece from being stripped. 5.6 Roller press l Structure: Two rollers are arranged horizontally up and down l Frame: "mouth" type casting arch l Bearing seat: 45 cast steel l Base: overall base l Roll size: φ400mm×450mm l Roll material: 9Cr3Mo (electroslag remelting) l The depth of the quenched layer of the roll surface: ≥18mm, the roll is quenched and tempered HB280-300. l Roll surface roughness Ra≤0.2um l Roll cylindricity≤±0.001mm l Tolerance of radial runout of roll assembly machine: ≤±0.002mm l Heat roller structure: solid roller with heating hole l Heating connection mode: the shaft end is connected by RHG rotary joint l Roll heating method: mold temperature heating controller l Heating medium: heat transfer oil l Heating temperature: room temperature~120℃, continuously adjustable, controlled by digital display temperature controller l Roll surface temperature uniformity error (working surface): ≤±1℃ l Adjustment accuracy: ±0.5℃ l Heating speed: heating from room temperature to 80℃, heating ≤100 minutes; heating at room temperature to 120℃, heating ≤150 minutes l Heating power: 45kW l Preset line pressure of roller press: 5t/cm l Roll gap adjustment range: 0-2mm, touch screen display. l Roll gap adjustment: Servo motor drives the middle wedge to adjust through the ball screw l Adjustment accuracy: 0.001mm l Maximum pressure between two rollers: 1800KN (pressurized by gas-liquid booster pump) l Drive: The geared motor is connected to the rolls through the elastic pin connector, and the rolls are driven by gears l Main motor power: 7.5KW (380V 50HZ variable frequency speed regulating motor) l Rolling speed: 1-12m/min (stepless speed regulation) l Electrical control: PLC program control, touch screen operation. l Work pressure: gas-liquid booster pump l Pressure method: lower hydraulic cylinder and upper pressure l Hydraulic cylinder diameter: φ220mm l Hydraulic system: the maximum pressure is 31.5MPa. l Host device size: (length × width × height) about 2800mm × 950mm × 1930mm l Arrangement: Left/Right (the power-driven part on the left side of the feed end is the left type, and the right side is the right type) l Appearance of equipment: The color is international standard warm gray 1C or customized according to customer requirements l Host weight: about 6 tons 5.7 Rear vibration damping device l Function: reduce the jitter of the pole piece during the rolling process and prevent the strip from breaking l Composition: fixed guide roller, floating guide roller, fixed bracket, etc. l Principle: The pole piece passes through the floating guide roller to reduce the jitter of the pole piece and prevent the pole piece from being stripped. 5.8 Winding device l Function: Collect the rolled pole pieces into coils l Composition: Inflatable shaft, deviation correction, magnetic powder clutch, winding reducer, frame, etc. l Principle: After rolling, the pole pieces are collected into coils, and the edges of the coils are neatly controlled by the correction mechanism. l Rewinding inflatable shaft: Φ74mm with inflatable gun l Effective use length of inflatable shaft: 550mm l Tension adjustment (setting) range: 1~20kgf l Tension control accuracy: 5% l Correction control: infrared photoelectric correction l Correction stroke: ±50mm l Edge control: deviation correction accuracy is ≤±0.2mm l Magnetic powder clutch: 50Nm l Winding power: 1.5KW reduction motor 5.9 Drive control system l The drive of each component of the entire continuous rolling production line is driven by motors of different specifications and models, which are centrally operated on the operation panel, and all drive motors are equipped with overload protection; l The control part includes: touch screen, PLC, main motor inverter, roller gap servo motor driver, tension controller, correction controller, etc. l The operation of the system adopts PLC control, touch screen and button operation mode, and emergency stop buttons are provided at the suspension operation station, the rolling mill feed end, and the winding and unwinding operation end to ensure the safety of the operator l The main control items of the system include: l Roller press start, stop, indication, overload protection l Hydraulic system start, stop, instruction l Rolling speed setting, speed display l Pressure setting, pressure display l With roller pressure parameters (pressure, roller gap) clearing and memory function l Rolling parameters can be automatically restored according to the pole piece model l Meter counting function l Abnormal alarm function l Equipped with MES data output docking function, docking method and database collection method are provided by the buyer 5.10 Roller disassembly device l Function: This device is used for roll replacement or maintenance, reducing the operation time of disassembling rolls and reducing the labor intensity of operators l Composition: consists of a roll-removing bracket, a roll-removing guide rail, etc. l Operation: When disassembling the roll, push the roll and the chock out of the dismounting guide rail, and use a crane or forklift to disassemble the rolls and transport them out. The installation is carried out in the opposite steps. 6.Configuration list No. Name Brand/Model Note 1 Roller Xingtai Sinosteel Certificate of conformity 2 Bearing Bush / Luo shaft 3 Reducer Boneng/Guomao 4 PLC Siemens/Delta 5 Touch screen Siemens/Delta 6 Frequency converter Siemens/Delta 7 Roll gap adjustment servo system Siemens/Delta 8 Electrical components Schneider, Chint 9 EPC Aibo/Timaco 10 Gas-liquid booster pump United States AZ 11 Pneumatic Components Airtac/SMC Air pipe is blue 7.Spare parts list No. Name Quantity Unit Note 1 Doctor blade 4 pcs 2 Upper cutter blade 2 pcs 3 Lower cutter blade 2 pcs 4 Hydraulic line seals 2 set 5 Roll changing accessories 1 set 1 set per workshop 6 Simple equipment maintenance tool 1 set Toolbox 8.Consumable parts list No. Name Specification Quantity Brand Reference replacement cycle 1 Doctor blade 0.2*30*450mm 2 Switzerland 15 days 2 Upper cutter blade Φ100*1.2 2 Domestic 15 days 3 Lower cutter blade Φ100*2 2 Domestic 15 days 4 Roller Φ400*450 2 Sinosteel 6 months (Grind) 5 Gear oil VG320 50L Great Wall 12 months 6 Hydraulic oil L-HV150 20L Great Wall 12 months 7 Low friction cylinder 2 Airtac/SMC 2 years 8 Three-axis cylinder 2 Airtac/SMC 2 years 9 Ultra-thin cylinder 4 Airtac/SMC 2 years 10 Pull valve 5 Airtac/SMC 2 years 11 The electromagnetic valve 4 Airtac/SMC 2 years 12 Axial fan 2 2 years 13 Potentiometer 1 Schneider 2 years

-

S65 Three Roller Grinding Machine Laboratory Three Roller Machine

S65 Three Roller Grinding Machine Laboratory Three Roller Machine

Roller mill iis designed for manufacture who wanna achieve accurate dispersion control and production of fine particles. It supply customers effective and extremely accurate means of reducing particle size and dispersion, with significant reproducibility. As far as product R&D, small scale production and the establishment of small production lines. DS type three roller mill can provide flexible, precise control to meet your requirements, and process parameters will provide a rigorous technical basis for the expansion of reproduction.

-

Lab Type Three Roller Mill Machine with Zirconia Roller or Stainless Steel Roller or Alloy Roller

Lab Type Three Roller Mill Machine with Zirconia Roller or Stainless Steel Roller or Alloy Roller

Roller mill iis designed for manufacture who wanna achieve accurate dispersion control and production of fine particles. It supply customers effective and extremely accurate means of reducing particle size and dispersion, with significant reproducibility. As far as product R&D, small scale production and the establishment of small production lines. DS type three roller mill can provide flexible, precise control to meet your requirements, and process parameters will provide a rigorous technical basis for the expansion of reproduction.

-

Strengthen Three Roll Mill for Mass Production

Strengthen Three Roll Mill for Mass Production

Roller mill iis designed for manufacture who wanna achieve accurate dispersion control and production of fine particles. It supply customers effective and extremely accurate means of reducing particle size and dispersion, with significant reproducibility. As far as product R&D, small scale production and the establishment of small production lines. DS type three roller mill can provide flexible, precise control to meet your requirements, and process parameters will provide a rigorous technical basis for the expansion of reproduction.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588