products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Prismatic Cell 10 Channel Auto Sorting Machine

Model Number:

TMAX-YLD-FX112Type:

Semi-AutomaticInput Power:

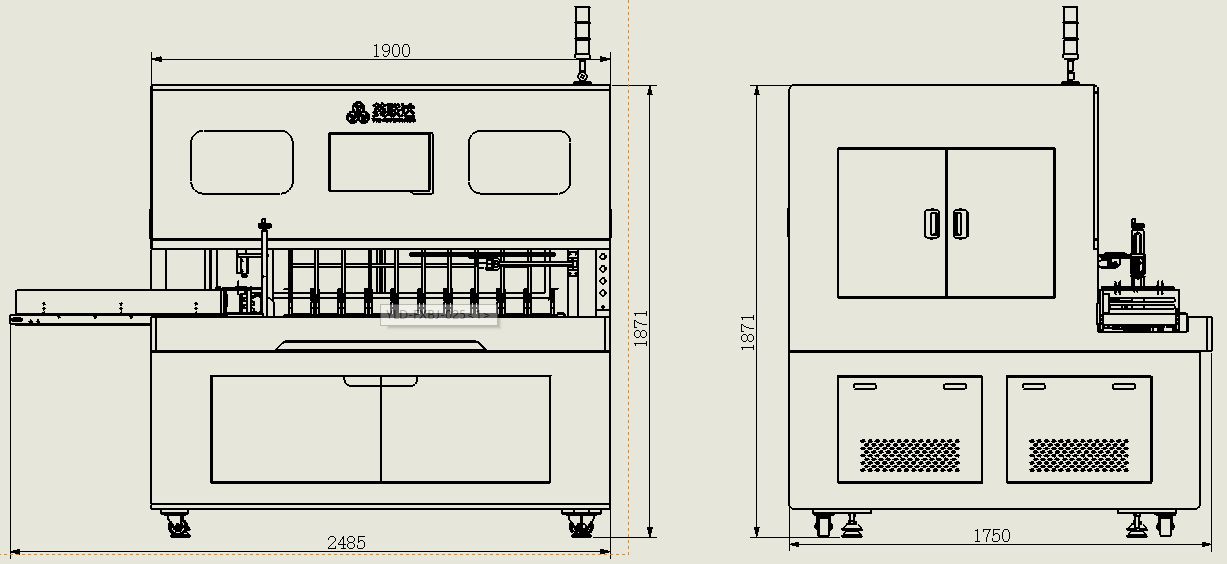

1.2KWDimension(L*W*H):

L 2485mm*W 1750mm*H 1871mmNet Weight:

about 600KgCompliance:

CE CertifiedWarranty:

1 Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

45 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

8 Channels Automatic Sorting Machine for Prismatic Battery CellNext:

Prismatic Battery Cell 8 Channels Automatic Sorting Machine

Prismatic Cell 10 Channel Auto Sorting Machine

Ⅰ、Equipment Introduction

1、Function Overview:

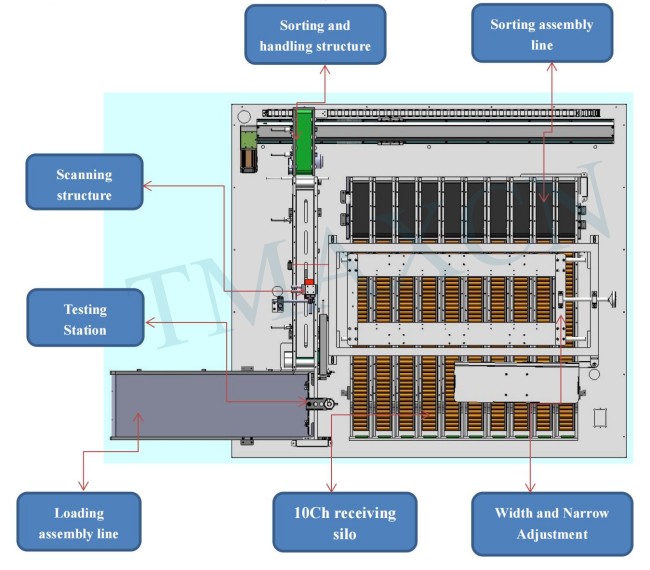

TMAX-YLD-FX112 10 Channel prismatic cell sorting machine is an automatic sorting equipment suitable for square shell batteries. The device tests the voltage internal resistance voltage of the square shell battery cells through a voltage internal resistance tester, and tests the parameters of each cell according to the upper computer software settings. According to the judgment results, different levels of batteries are moved to different channels to achieve automatic sorting of battery products (the device has a scanning data storage function). The equipment consists of a feeding mechanism, a testing mechanism, a scanning mechanism, an automatic sorting mechanism, etc. According to user requirements, upper computer software is designed and developed to automatically sort and collect battery cells into their corresponding receivers based on group information. The operation is simple, the sorting is accurate, and the efficiency is high.

2、Overview of Work Steps:

The ten level square sorting machine consists of a feeding mechanism, a testing mechanism, a scanning mechanism, an automatic sorting and receiving mechanism, etc. Firstly, the entire battery is manually placed on the feeding assembly line, which sends the batteries one by one to the testing area for data testing. Then, the batteries are scanned and bound to the QR code in the scanning area, and the test data is bound to the QR code. After the scanning is completed, the sorting machine uses a mechanical arm to put cells of different voltages into the sorting assembly line and flow them into the corresponding level receiving bin. This cycle of work continues.

3、Equipment dimensions and specifications:

4、Equipment structure layout diagram:

Ⅱ、Equipment parameters:

SN |

Specification |

|

1 |

Weight |

about 600Kg |

2 |

Equipment dimensions |

L*W*H:2485mm*1750mm*1871mm |

3 |

Power supply |

AC 220V 50Hz |

4 |

Power |

1.2KW |

5 |

Work environment requirements |

Temperature: 0℃-50℃,No pollution and strong electromagnetic interference |

6 |

Gas source requirements |

0.5~1.0Mpa ,Factory gas source,0.5-0.7Mpa ,compressed air |

Equipment system technical parameters |

||

1 |

Sorting channel |

10 |

2 |

Internal resistance detection accuracy |

Range: 0-60 mΩ;Accuracy:±0.5% rdg ;resolution ratio :0.1mΩ |

3 |

Voltage measurement accuracy |

Range: 0-60V;Accuracy:±0.015% rdg ;resolution ratio : 0.1mV |

4 |

NG Equipment failure rate |

≤2%(Malfunctions caused solely by equipment) |

5 |

Probability of product damage |

≤0.1% |

6 |

Equipment production capacity speed |

10-15PPM |

7 |

Suitable for battery models |

Prismatic cell |

Ⅲ、Equipment main component configuration brand:

Constituent part |

Accessory Name |

Brand |

Mechanical part |

Screw and guide rail |

HIWIN/TBI |

|

Bearings and support seats |

NSK |

|

Machining and sheet metal |

TMAX |

Electrical part |

Industrial computer and board |

Yan Hong、Leisai |

|

Display |

Lenovo, Dell |

|

Servo |

Hechuan and Xinjie |

|

Source |

Taiwan Mingwei |

|

Inductor |

Yadeke, Omron |

|

Control switch |

Chint |

|

Button |

Zerbo |

|

QR code scanner |

Keinz, Cognex |

|

Tester |

HIOKI |

Pneumatic system |

Pneumatic components |

AirTAC |

Ⅳ、Machine Picture

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588