products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

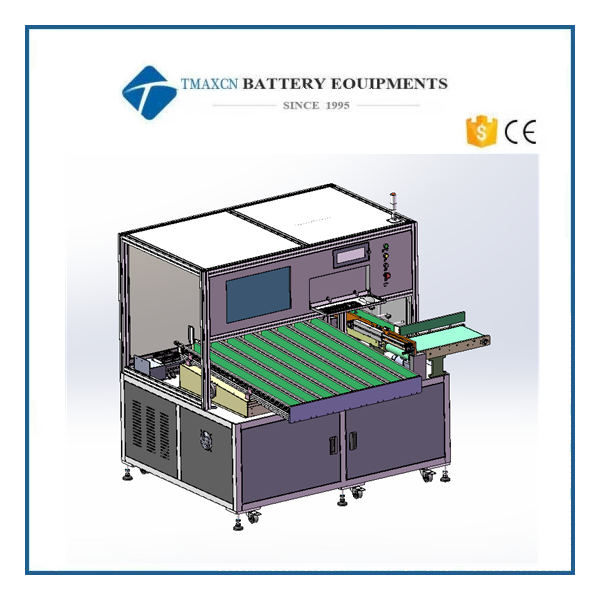

8 Channels Automatic Sorting Machine for Prismatic Battery Cell

Model Number:

TMAX-ZW-FFX8SType:

Semi-AutomaticDimension(L*W*H):

1945*1600 *1600 mmCompliance:

CE CertifiedWarranty:

1 Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

30 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

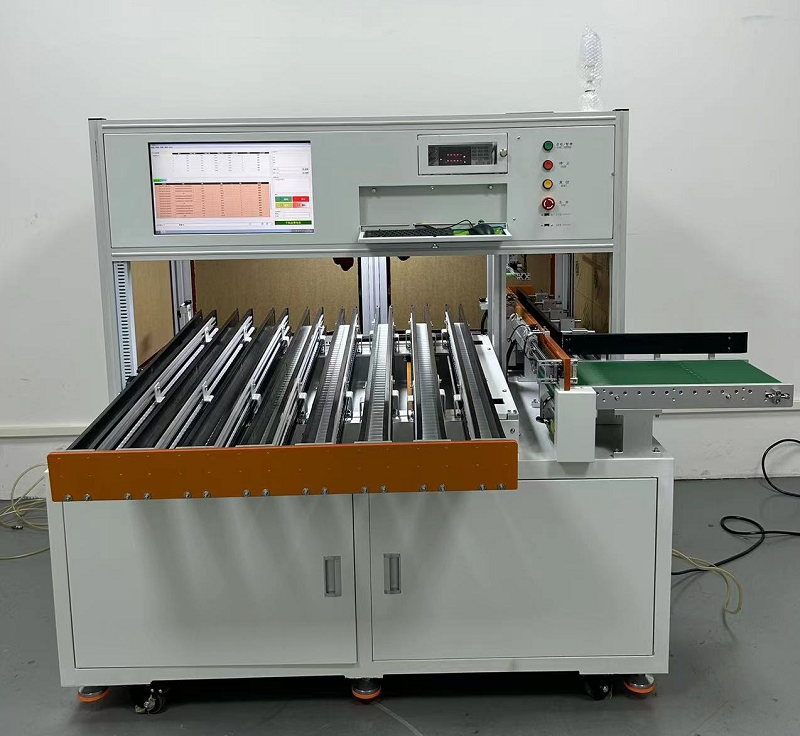

8 Channels Automatic Sorting Machine for Prismatic Battery Cell

I.Equipment adaptation range

Universal sorting and grouping of square shell batteries.

II.Equipment Overview

The TMAX-ZW-FFX8S 8-speed sorting machine is suitable for sorting and grouping testing of general-purpose prismatic cell batteries. This machine adopts a belt line driven feeding method, which is easy to change and can analyze and save test data of square shell batteries. Defective batteries are uniquely removed, and the sorted and paired batteries are collected by the receiving groove, making it convenient for operators to manage.

III.Functional characteristics

● Equipped with industrial control integration, all parameters of the battery can be traced and tracked, facilitating data management and simple operation. Management functions such as battery voltage, battery internal resistance, and configuration information.

● Adapted to various types of batteries, easy to replace and operate.

● Built in high-precision Japanese BT3562A internal resistance tester, with high testing accuracy and fast speed.

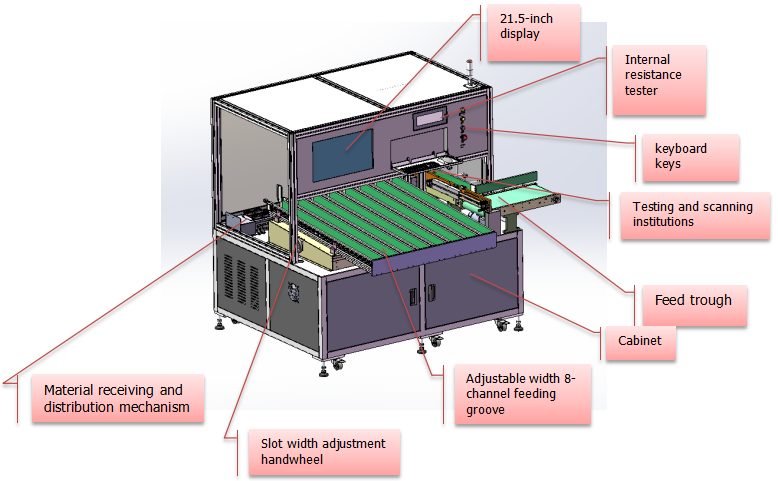

IV.Equipment structure

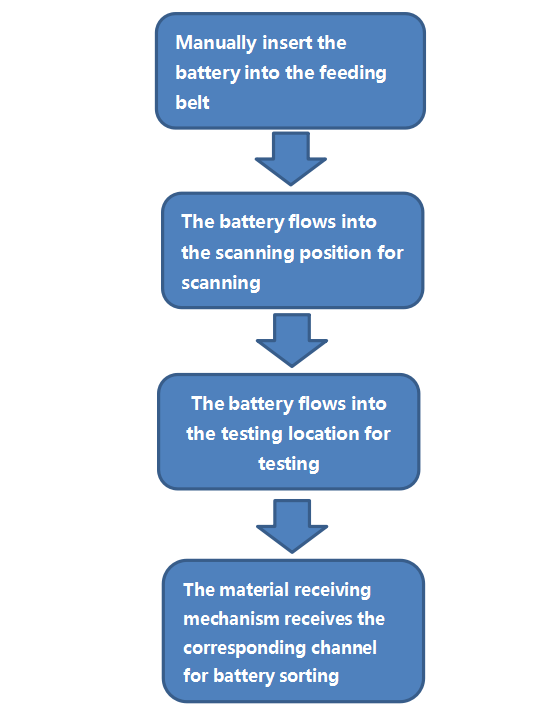

V.Workflow

VI.Technical Parameter

Equipment efficiency |

10-12PPM |

Equipment turnover rate |

≥ 95% |

Number of sorting channels |

8 (7 good products, 1 defective product) |

Applicable battery size |

Length: 100-220mm, width: 20-80mm, height: 110-220mm |

Instrument internal resistance detection accuracy |

+/-0.5% rdg, display resolution 0.01 milliohms |

Instrument voltage detection accuracy |

+/-0.05% rdg, display resolution: 0.1 millivolts |

Internal resistance detection repetition error |

< 1 milliohm (AC internal resistance detection method) |

Voltage detection repetition error |

< 1 millivolt |

control system |

PC industrial control computer (embedded system) |

Input power consumption |

1KW |

Input power supply |

AC220V/50HZ |

Compressed air source |

≥ 0.6Mpa |

display |

21.5-inch Philips large display screen |

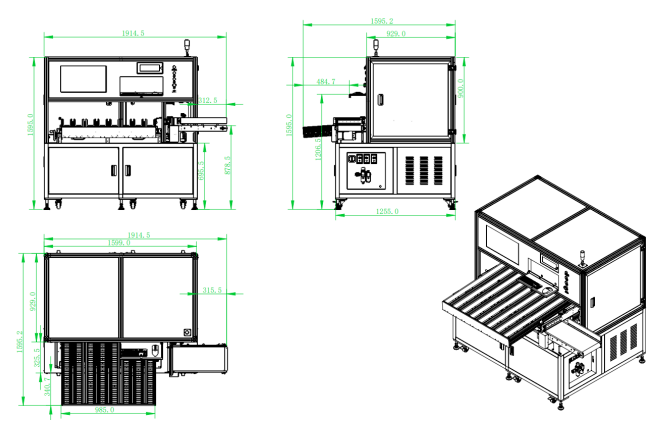

Equipment appearance reference size |

L * W * H=1945 * 1600 * 1600mm |

Overall weight |

350KG |

VII.External dimension diagram

VIII.List of Key Components

Key component names |

Brand |

Place of origin |

Guide rail |

Jieyin |

Taiwan |

Industrial computer |

Jianuo |

China |

PLC |

Xinjie |

China |

servo motor |

Xinjie |

China |

Speed regulating motor |

Tai Li |

China |

display |

Philips 21.5 inches |

China |

drive |

Xinjie |

China |

source |

Jin Shengyang |

China |

solenoid valve |

stars |

China |

cylinder |

stars |

Taiwan/China |

Photoelectric sensor |

Omron, Huayifeng |

Japan/China |

Internal resistance tester |

Japanese BT3562A |

Japan |

QR code scanner |

MINDEO |

China |

IO Wiring Table:

Input |

Name |

output |

Name |

X0 |

Y-axis servo alarm signal |

Y0 |

Y-axis pulse |

X1 |

Y-axis origin |

Y1 |

Y-axis direction |

X2 |

Y-axis right limit position |

Y2 |

Conveyor belt motor |

X3 |

Y-axis left limit position |

Y3 |

Test belt motor |

X4 |

Transport reflection photoelectric detection |

Y4 |

Module belt motor forward rotation |

X5 |

Conveyor blocking cylinder extension |

Y5 |

Module belt motor reverse |

X6 |

Transport blocking cylinder retraction |

Y6 |

Unloading belt motor |

X7 |

Test 1 # Reflective photoelectric detection |

Y7 |

Transport blocking cylinder release (retraction) |

X8 |

Test blocking cylinder extension |

Y8 |

Transport blocking cylinder blocking (extending) |

X9 |

Test blocking cylinder retraction |

Y9 |

Test blocking cylinder release (retraction) |

X10 |

Test 2 # Reflective photoelectric detection |

Y10 |

Test blocking cylinder blocking (extending) |

X11 |

Scan code to read |

Y11 |

red light |

X12 |

Test the descent of the lifting cylinder |

Y12 |

Yellow light |

X13 |

Test the lifting cylinder to rise |

Y13 |

green light |

X14 |

Module 1 # Reflective photoelectric detection |

Y14 |

|

X15 |

Module 2 # Reflective photoelectric detection |

Y15 |

|

X16 |

Rack photoelectric detection |

Y16 |

|

X17 |

Start button |

Y17 |

|

X18 |

Stop button |

Y18 |

|

X19 |

Emergency stop button |

Y19 |

|

X20 |

Reset button |

Y20 |

|

Machine parameters:

11.1 Equipment power supply: two-phase~220V ± 10%/50Hz ± 10%

11.2 Overall power: 2000W

11.3 Equipment air pressure: 0.5~0.6Mpa

11.4 Equipment weight: 350 KG;

11.5 External dimensions:L1945mm*W1600mm*H1600mm;

11.6 Usage environment:

11.6.1Please avoid using this equipment in places with high temperature, humidity, vibration or impact, metal powder, and welding spatter. Pay attention to controlling the temperature of the surrounding environment of the equipment;

11.6.2 The equipment must be grounded and separated from the personnel grounding line;

11.7 Equipment service life: more than 5 years.

![]()

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588