products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Pouch Cell Heat Vacuum Sealing Machine with Automatic Puncture Function for Final Sealing

Pouch Cell Heat Vacuum Sealing Machine with Automatic Puncture Function for Final Sealing

final vacuum sealing machine

-

Pouch Cell Vacuum Heating Final Sealing Machine

Pouch Cell Vacuum Heating Final Sealing Machine

Pouch Cell Vacuum Heating Final Sealing Machine

-

Hot Press Pressure Pouch Cell Formation Machine

Hot Press Pressure Pouch Cell Formation Machine

-

Lithium ion Battery Making Machine Solvent Processing System Waste Gas Treatment Equipment For Pouch Cell

Lithium ion Battery Making Machine Solvent Processing System Waste Gas Treatment Equipment For Pouch Cell

-

Automatic Pouch Cell Die Cutter for Battery Electrode

Automatic Pouch Cell Die Cutter for Battery Electrode

-

3-in-1 Hot Sealer for Pouch Cell Preliminary Top/Side Sealing &Vacuum Sealing, and Vacuum Standing

3-in-1 Hot Sealer for Pouch Cell Preliminary Top/Side Sealing &Vacuum Sealing, and Vacuum Standing

DESCRIPTION:MSK-115-III is a 3-in-1 compact hot sealer. the preliminary sealing top and side of the pouch cell before electrolyte injection (MSK-140) the vacuum sealing for the pouch case after injection of electrolyte in the glove box (MSK-115A) the vacuum standing for the electrolyte diffusion and degassing (MSK-170) It is designed for Li-S pouch cell preparation in glove-box for the space saving. MSK-115-III is an upgraded version from MSK-115A with an extra top&side sealing function and a vacuum timer. MSK-115-III has been upgraded from MSK-115-AB since 08/24/2017.

-

Lab Electrode Die Cutter for Pouch Cell Electrodes Cutting

Lab Electrode Die Cutter for Pouch Cell Electrodes Cutting

MSK-180S is a gas driven die cutter for producing pouch battery cathode/anode electrodes ( no electricity required ) Its compact design enables the operation inside a glove box with Ar atmosphere where moisture/oxygen-sensitive electrodes will be cut

-

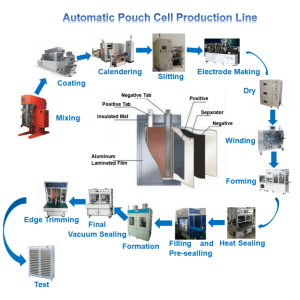

Automatic Pouch Cell Production Equipment Line For Li Ion Battery Making

Automatic Pouch Cell Production Equipment Line For Li Ion Battery Making

-

Pouch Cell Lab Pilot Assembly Machine Line for Pouch Battery Preparation

Pouch Cell Lab Pilot Assembly Machine Line for Pouch Battery Preparation

-

Coin Cell Laboratory Assembly Equipment Production Line

Coin Cell Laboratory Assembly Equipment Production Line

Coin Cell Laboratory Assembly Equipment Production Line Related Machine for Coin Cell Preparation No. Machine 1 Tube Furnace/Muffle Furnace 2 Planetary Ball Mill 3 Vacuum Mixer 4 Film Coater Machine 5 Roll Press Machine 6 Punching Machine 7 Vacuum Drying Oven 8 Glove Box Machine 9 Sealing Machine 10 Battery Tester Machine 11 E-mail: David@tmaxcn.com

-

Double Servo High Speed Automatic Die Cutting Machine for Pouch Cell

Double Servo High Speed Automatic Die Cutting Machine for Pouch Cell

MSK-180S is a gas driven die cutter for producing pouch battery cathode/anode electrodes ( no electricity required ) Its compact design enables the operation inside a glove box with Ar atmosphere where moisture/oxygen-sensitive electrodes will be cut

-

Automatic Double Servo High Speed Die Cutting Machine

Automatic Double Servo High Speed Die Cutting Machine

MSK-180S is a gas driven die cutter for producing pouch battery cathode/anode electrodes ( no electricity required ) Its compact design enables the operation inside a glove box with Ar atmosphere where moisture/oxygen-sensitive electrodes will be cut

-

Pouch Cell Semi Automatic Electrolyte Filling Machine with Sealing and Diffusion&Degassing Function

Pouch Cell Semi Automatic Electrolyte Filling Machine with Sealing and Diffusion&Degassing Function

MSK-180S is a gas driven die cutter for producing pouch battery cathode/anode electrodes ( no electricity required ) Its compact design enables the operation inside a glove box with Ar atmosphere where moisture/oxygen-sensitive electrodes will be cut

-

Automatic Double Servo High Speed Die Cutting Machine

Automatic Double Servo High Speed Die Cutting Machine

MSK-180S is a gas driven die cutter for producing pouch battery cathode/anode electrodes ( no electricity required ) Its compact design enables the operation inside a glove box with Ar atmosphere where moisture/oxygen-sensitive electrodes will be cut

-

Pouch Cell Automatic Layer by Layer Stacker Stacking Machine

Pouch Cell Automatic Layer by Layer Stacker Stacking Machine

MSK-111A-E is a high-accuracy automatic stacking machine with many advanced features to ensure a stable, repeatable and precise electrode stacking. In its "Z" fashion stacking method, Anode and Cathode electrodes are alternatively stacked with the seperator film in between. Advanced Features: PLC Touch Screen Control allows easy condition setting Continuous "Z" fashion stacking with a separator Auto electrode pick-up & stacking via vacuum suction manipulator Adjustable mechanical fixture for accurate electrodes positioning Unreeling rotors for separator film feeding Auto-tension control for separator film delivery One set of 80x50mm stocking die fixture is included for immediate use.

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588