products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Hot Press Pressure Pouch Cell Formation Machine

Hot Press Pressure Pouch Cell Formation Machine

-

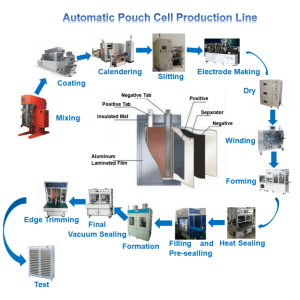

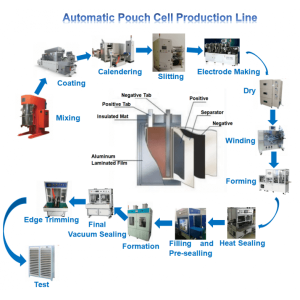

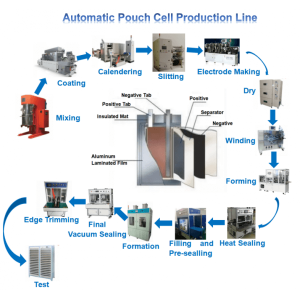

Automatic Pouch Cell Production Equipment Line For Li Ion Battery Making

Automatic Pouch Cell Production Equipment Line For Li Ion Battery Making

-

Three-station Two Chamber Final Sealing & Edge Trimming Machine

Three-station Two Chamber Final Sealing & Edge Trimming Machine

The film coater is a Large Automatic Film Coater designed to produce films with consistent thickness by using micrometer adjustable applicators or fixed thickness applicators. It has an unique driving system to produce smooth coating on all types of materials. One micrometer adjustable applicator is included for immediate use.

-

Automatic Pouch Cell Production Manufacturing Machine Line For Making Li Ion Battery

Automatic Pouch Cell Production Manufacturing Machine Line For Making Li Ion Battery

-

Automatic Pouch Cell Manufacturing Production Plant For Pouch Cell Assembing

Automatic Pouch Cell Manufacturing Production Plant For Pouch Cell Assembing

Automatic Pouch Cell Manufacturing Production Plant For Pouch Cell Assembing

-

Semi-auto Pouch Cell Lithium Battery Fabrication Equipment for Pouch Cell Production Line

Semi-auto Pouch Cell Lithium Battery Fabrication Equipment for Pouch Cell Production Line

-

Automatic Rotary Vacuum Sealer with Auto Puncture Function for Pouch Cell Making

Automatic Rotary Vacuum Sealer with Auto Puncture Function for Pouch Cell Making

Automatic Rotary Vacuum Sealer with Auto Puncture Function for Pouch Cell Making Main components of the equipment 1. Vacuum chamber: turntable mechanism driven by brake motor. 2. Bayonet mechanism: with vacuum display. 3. Display and control touch screen control panel (including heat sealing time control, manual single action operation mode, etc.). 4. The whole machine body adopts aluminum profile structure, all parts are surface treated to prevent electrolyte corrosion, and there are protective safety doors to prevent accidents. 5. The vacuum value can be detected and displayed by SMC negative pressure sensor, and the vacuum value can be set according to the process requirements. 6. Electrical control system. Features 1. Double position turntable cam splitter drive; 2. The rotary table and cavity are made of corrosion-resistant materials (aluminum oxidation); 3. Preset packaging temperature, extraction time and packaging time; 4. Independent temperature control of upper and lower heads, with alarm function of too low and too high temperature; 5. The air supply pressure of head cylinder can be adjusted and displayed; 6. Digital display of vacuum degree, clear display, convenient setting and adjustment; 7. The battery is provided with a pressing plate to flatten and compress; 8. The parallelism of upper and lower heads: ± 0.01mm; the alignment can be adjusted by adjusting mechanism, and the hot head can be adjusted automatically by flat pressure. 9. The upper head and bayonet can be lifted automatically to separate from the vacuum chamber, and the lower head cavity is convenient for disassembly and maintenance; 10. Configure electrolyte separation barrel, optimize electrolyte discharge channel, reduce pollution of vacuum source; 11. Set safety door switch protection; 12. PLC is used to realize automatic control and touch screen is used to realize man-machine dialogue, which is convenient for operation and setting; 13. It has output statistics function, manual and automatic operation function, and fault alarm function; 14. Safe and stable operation, reliable control and convenient operation; Specifications Power Supply 220V, 50/60Hz, single phase Applicable max. battery size 300mm X 300 mmX 12mm Pressure 0.5-0.7MPa Vacuum degree -98Kpa Machine working cycle About 10sec/time Sealing head length 300mm Sealing width 8mm Sealing thickness 0.14-0.3mm Head temperature Room temperature~300℃ adjustable, compensation can be set, control accuracy±2℃ Packaging time 0-99.9 seconds adjustable Head parallelism ±0.01mm Equipment capacity 100-500 EA / h (depending on worker's proficiency) Equipment turnover rate ≥98% Machine size 1300(L) X1300mm (W) X1780mm (H Equipment weight 250KG

-

Automatic Rotary Vacuum Sealer Machine with Auto Puncture Function for Pouch Cell Making

Automatic Rotary Vacuum Sealer Machine with Auto Puncture Function for Pouch Cell Making

Automatic Rotary Vacuum Sealer with Auto Puncture Function for Pouch Cell Making Main components of the equipment 1. Vacuum chamber: turntable mechanism driven by brake motor. 2. Bayonet mechanism: with vacuum display. 3. Display and control touch screen control panel (including heat sealing time control, manual single action operation mode, etc.). 4. The whole machine body adopts aluminum profile structure, all parts are surface treated to prevent electrolyte corrosion, and there are protective safety doors to prevent accidents. 5. The vacuum value can be detected and displayed by SMC negative pressure sensor, and the vacuum value can be set according to the process requirements. 6. Electrical control system. Features 1. Double position turntable cam splitter drive; 2. The rotary table and cavity are made of corrosion-resistant materials (aluminum oxidation); 3. Preset packaging temperature, extraction time and packaging time; 4. Independent temperature control of upper and lower heads, with alarm function of too low and too high temperature; 5. The air supply pressure of head cylinder can be adjusted and displayed; 6. Digital display of vacuum degree, clear display, convenient setting and adjustment; 7. The battery is provided with a pressing plate to flatten and compress; 8. The parallelism of upper and lower heads: ± 0.01mm; the alignment can be adjusted by adjusting mechanism, and the hot head can be adjusted automatically by flat pressure. 9. The upper head and bayonet can be lifted automatically to separate from the vacuum chamber, and the lower head cavity is convenient for disassembly and maintenance; 10. Configure electrolyte separation barrel, optimize electrolyte discharge channel, reduce pollution of vacuum source; 11. Set safety door switch protection; 12. PLC is used to realize automatic control and touch screen is used to realize man-machine dialogue, which is convenient for operation and setting; 13. It has output statistics function, manual and automatic operation function, and fault alarm function; 14. Safe and stable operation, reliable control and convenient operation; Specifications Power Supply 220V, 50/60Hz, single phase Applicable max. battery size 300mm X 300 mmX 12mm Pressure 0.5-0.7MPa Vacuum degree -98Kpa Machine working cycle About 10sec/time Sealing head length 300mm Sealing width 8mm Sealing thickness 0.14-0.3mm Head temperature Room temperature~300℃ adjustable, compensation can be set, control accuracy±2℃ Packaging time 0-99.9 seconds adjustable Head parallelism ±0.01mm Equipment capacity 100-500 EA / h (depending on worker's proficiency) Equipment turnover rate ≥98% Machine size 1300(L) X1300mm (W) X1780mm (H Equipment weight 250KG

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588