products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Manual 10T 20T C Type Landing Single Column Servo Oil Hydraulic Press Machine

Model Number:

TMAX-BSW07-10TCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

10T Four Column Servo Press Intelligent Precision Automatic Hydraulic Press MachineNext:

60T Intelligent Precision Servo CNC Automatic Oil Hydraulic Press

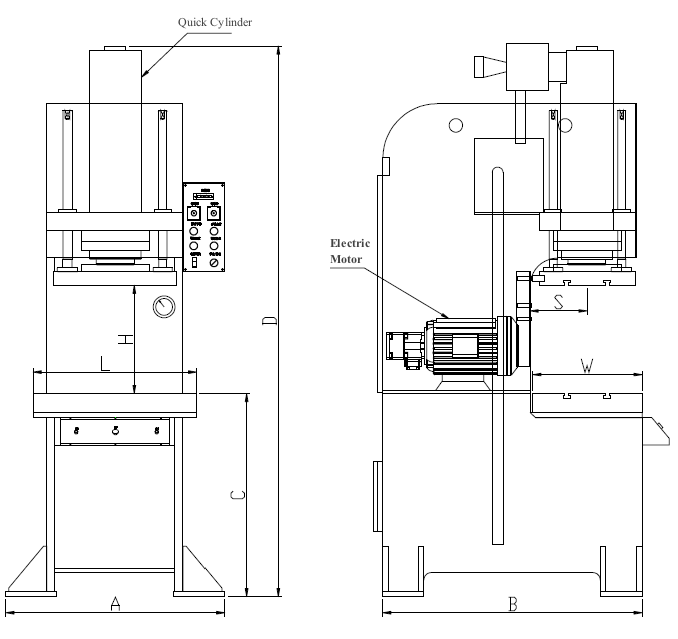

Manual 10T 20T C Type Landing Single Column Servo Oil Hydraulic Press Machine

Introduction

The single-column hydraulic machine body is a C-type floor-standing structure, open on three sides, easy to operate, and tempered after welding to ensure that the frame will never deform. It is mainly used for press fitting, assembly, shallow drawing of metal products, and forming pressing. , embossing, is a general-purpose equipment for motors, shafts, auto parts, electronic hardware products, internal combustion engines, textile machinery, washing machines, electrical appliances and other factories.

Product parameters

Model |

BSW07 -10T |

BSW07 -20T |

BSW07 -30T |

BSW07 -40T |

BSW07 -50T |

BSW07 -60T |

|

Nominal pressure(T) |

10 |

20 |

30 |

40 |

50 |

60 |

|

Maximum working pressure of liquid(Mpa) |

21 |

21 |

21 |

21 |

21 |

21 |

|

Surface height (E) mm |

850 |

850 |

850 |

850 |

850 |

850 |

|

Maximum opening distance(H)mm |

400 |

400 |

500 |

550 |

550 |

600 |

|

Deep throat (s) mm |

200 |

200 |

225 |

225 |

250 |

250 |

|

Maximum stroke(mm) |

300 |

300 |

300 |

300 |

300 |

400 |

|

Work bench size

|

Left and right (L) mm |

500 |

500 |

550 |

550 |

650 |

650 |

Before and after (W) mm |

400 |

400 |

450 |

450 |

500 |

500 |

|

Speed |

Rated load speed (mm/s) |

165 |

165 |

165 |

165 |

155 |

155 |

Working speed(mm/s) |

24 |

24 |

24 |

18 |

15 |

15 |

|

Return speed(mm/s) |

140 |

140 |

140 |

125 |

125 |

125 |

|

Main frame size(mm) |

700x950x2050 |

700x950x2060 |

760x950x2100 |

780x950x2150 |

800x950x2150 |

830x1000x2350 |

|

Power(Kw) |

2.2Kw |

3.7 Kw |

3.7Kw |

3.7 Kw |

5.5 Kw |

5.5 Kw |

|

Features

1. Floor-standing hydraulic press has the characteristics of good rigidity, stability and high speed because it is a welding mechanism as a whole.

2. This series of hydraulic presses uses 2-20MPA liquid pressure as the power source, and external three-phase AC380V 50HZ or three-phase AC220 60HZ AC power supply.

3. This series of equipment uses liquid as the medium to transfer energy. It adopts advanced sub-cylinder hydraulic circuit, the oil temperature is low, the idle speed is above 150MM/sec, and the working speed is below 30 MM/sec.

4. The equipment is on standby, and the noise does not exceed 75 decibels when moving up and down.

5. It can be divided into manual and semi-automatic control modes. Manually, the press-fit upper mold can be stopped in any stroke range. It can be equipped with an emergency rebound button or an infrared hand guard device.

6. The press-fit stroke of this series of presses is generally controlled by a timer, pressure switch, position sensor, or the customer's own mold.

7. The height of the press-fit spindle can be adjusted by the timer or the position sensor within any stroke range.

8. Pressure, stroke, holding time, closing height can be adjusted by the customer for easy operation; with automatic counting function, can also be equipped with force measuring display, intelligent temperature controller, can be customized according to customer requirements.

9. The hydraulic mechanical output range of this series is available in various specifications of 15tf-100 tf. (1tf=1000kgf=9.8KN).

Dimension

Application

Pictures

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588