products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

60T Intelligent Precision Servo CNC Automatic Oil Hydraulic Press

Model Number:

TMAX-BSW07S-10TCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Manual 10T 20T C Type Landing Single Column Servo Oil Hydraulic Press MachineNext:

20T Precision CNC Servo Hydraulic Press Forming Machine for Ceramic Powder Molding

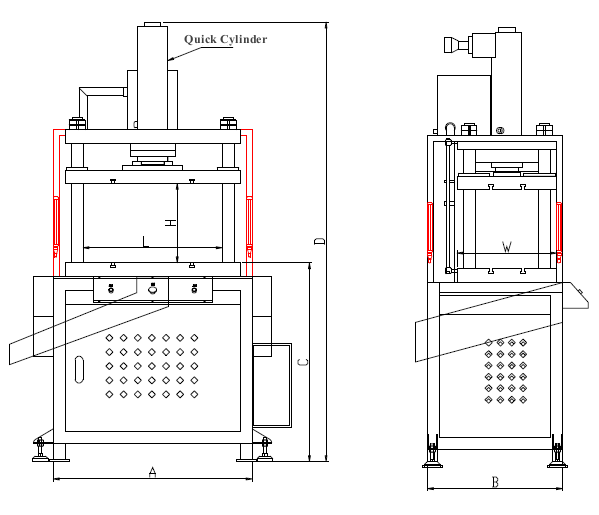

60T Intelligent Precision Servo CNC Automatic Oil Hydraulic Press

Introduction

The servo hydraulic press is a new type of energy-saving and high-efficiency hydraulic press that uses a servo motor to drive the main drive oil pump to reduce the control valve circuit and control the hydraulic press slider head.

The servo hydraulic press is a smart press that has been newly designed by Bussie Machinery R&D personnel through computer-aided design technology combined with years of design and development experience.

Product parameters

Model |

BSW07S -10T |

BSW07S -20T |

BSW07S -30T |

BSW07S -40T |

BSW07S -50T |

BSW07S -60T |

|

Nominal pressure(T) |

10 |

20 |

30 |

40 |

50 |

60 |

|

Maximum working pressure of liquid(Mpa) |

21 |

21 |

21 |

21 |

21 |

21 |

|

Surface height(E) mm |

850 |

850 |

850 |

850 |

850 |

850 |

|

Maximum opening distance(H)mm |

500 |

500 |

500 |

550 |

550 |

600 |

|

Deep throat(s) mm |

200 |

200 |

225 |

225 |

250 |

250 |

|

mm Maximum stroke |

300 |

300 |

300 |

300 |

300 |

400 |

|

Work bench size

|

Left and right(L) mm |

500 |

500 |

550 |

550 |

650 |

650 |

Before and after(W) mm |

400 |

400 |

450 |

450 |

500 |

500 |

|

Speed |

Rated load speed (mm/s) |

165 |

165 |

165 |

165 |

155 |

155 |

Working speed(mm/s) |

3-25 |

3-25 |

3-25 |

3-18 |

3-15 |

3-15 |

|

Return speed(mm/s) |

140 |

140 |

140 |

125 |

125 |

125 |

|

Main frame size(mm) |

700x950x2160 |

750x1000x2250 |

760x1000x2300 |

780x1050x2350 |

800x1060x2500 |

830x1100x2600 |

|

Power(Kw) |

3.7 Kw |

3.7 Kw |

5.5Kw |

7.5 Kw |

7.5 Kw |

11 Kw |

|

Features

1. This series of hydraulic presses is powered by 2-20MPA hydraulic pressure, with external three-phase AC380V 50HZ or three-phase AC220 60HZ AC power supply.

2. Energy saving: hydraulic and electric control adopt intelligent servo energy saving system, saving 30%-60% compared with traditional hydraulic machine.

3. Safety and precision: Each machine is equipped with infrared safety grating to effectively protect the operator and servo CNC precision control to ensure the repeatability of the machine can reach ±0.03mm and the pressure error is ±1%.

4. Low failure rate: servo control system, no useless work, oil temperature is not easy to rise, and there is no negative pressure in the oil circuit system, which greatly reduces the fault and prolongs the service life of the hydraulic components. Key reset function.

5. Stable and durable: the frame adopts the whole frame structure, the slider adopts the precision guide rail to run, the shock resistance and the anti-side pressure are strong, the whole machine is stable, precise and durable, suitable for precision press fitting, assembly, blanking, forming and extrusion. And many other process uses.

6. Convenient maintenance: The whole machine is designed according to different function modes and designed into a module structure. It is easy to disassemble and assemble. The general fault can be directly viewed through the touch screen, and the maintenance is simple.

Dimension

Application

Pictures

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588