products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Laboratory Intelligent -automatic Powder Tablet Press with Programmable Controller 20T to 100T

Model Number:

TMAX-ZYP-TSCompliance:

CE CertifiedWarranty:

One year limited standard warrantyPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

300C 500C 40T Lab Flat Automatic Hydraulic Hot Press with High Precision Pressure ControlNext:

Lab Widened Manual Integrated Hot Hydraulic Press with Double Heating Plates 300C 500C

Laboratory Intelligent -automatic Powder Tablet Press with Programmable Controller 20T to 100T

Features

Novel ZYP-TS liquid display series

ZYP-TS series automatic tablet press adopts new national technology. Compared with DYS-TS series electric tablet press, the biggest advantage is that the pressure system does not need conversion, directly set the pressure tonnage, and increase the timing pressure relief and cylinder limit protection function. The whole series is equipped with safety protection device, which is favored by users. Intelligent automatic program pressure/slow pressure - program control pressure - automatic pressure maintenance, automatic pressure supplement, timing pressure relief, with stable performance, easy operation, strong practicability, high safety advantages, suitable for high-end laboratory use.

This machine is often used in calcium and iron analyzer, Fourier infrared spectrometer (IR), teaching, testing, catalysis, pharmaceutical, chemical and new materials research and development and other fields.

Parameter

Model |

ZYP-20TS |

ZYP-30TS |

ZYP-40TS |

ZYP-60TS |

ZYP-100TS |

Pressure range |

1-20.0T |

1-30.0T |

1-40.0T |

1-60.0T |

1-100.0T |

Voltage regulation accuracy |

0.1t |

0.1t |

0.1t |

0.1t |

0.1t |

Maximum cylinder stroke |

30mm |

30mm |

50mm |

50mm |

50mm |

Pressure way |

Electric pressure |

||||

The sample preparation process |

Intelligent automatic, program pressure/slow pressure - program pressure holding/pressure supplement - timing pressure relief - demoulding sampling |

||||

Display mode |

XNNETs 4.3-inch LCD display |

||||

The time of holding pressure |

999 minutes and 59 seconds |

||||

Mold pressure conversion |

Program automatic conversion, digital display mold sample pressure (MPa) |

||||

Cylinder limit device |

Automatic pressure relief protection when the cylinder rises to the limit height |

||||

Safety device |

Steel plate protection with plexiglass protection door |

||||

Overall structure |

One-piece structure, no sealing link, reduce oil leakage |

||||

Power supply |

220V (50 hz / 60 hz) |

||||

Workspace |

140*160mm |

140*160mm |

175*180mm |

185*220mm |

185*250mm |

Overall dimensions |

230*390*420mm |

230*390*420mm |

280*460*550mm |

300*520*580mm |

330*580*620mm |

Weight |

90kg |

95kg |

150kg |

180kg |

240kg |

Description |

A full automatic tablet press, mold optional! Four pieces can be customized to increase the height, can be customized larger tonnage, larger space of the tablet press. |

||||

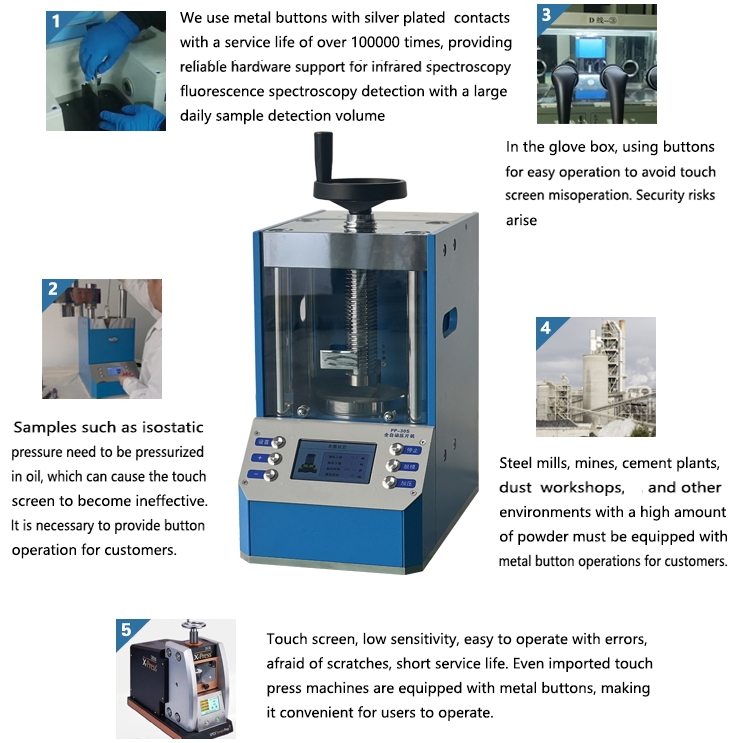

Advantages of metal button (service life > 100,000 times)

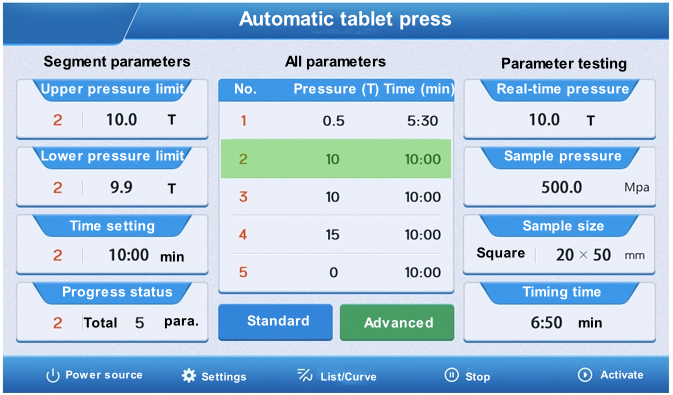

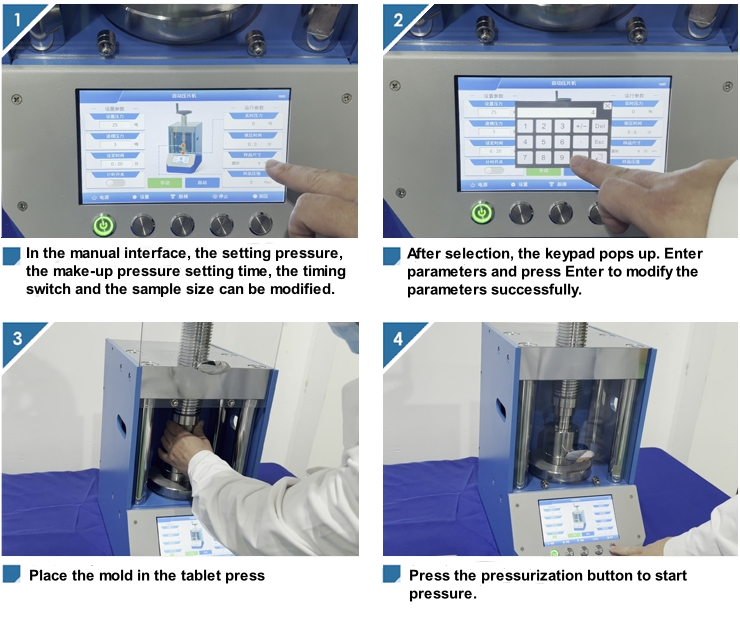

Operation interface (Manual mode)

Standard interface: Various parameters such as pressure, demoulding, time, sample size, etc. can be set in this interface alone.

Pressurization button: Press according to the parameters set on the interface.

Stop button: Press the stop button during the pressurization process to stop the pressurization.

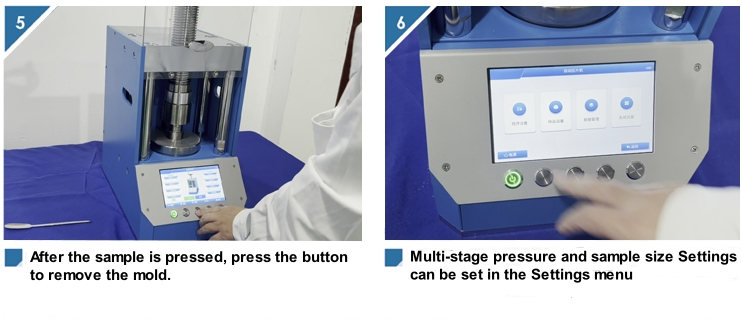

Demoulding button: Press the demoulding button to release the sample according to the demoulding pressure.

Timing switch: The timing function can be turned on and off.

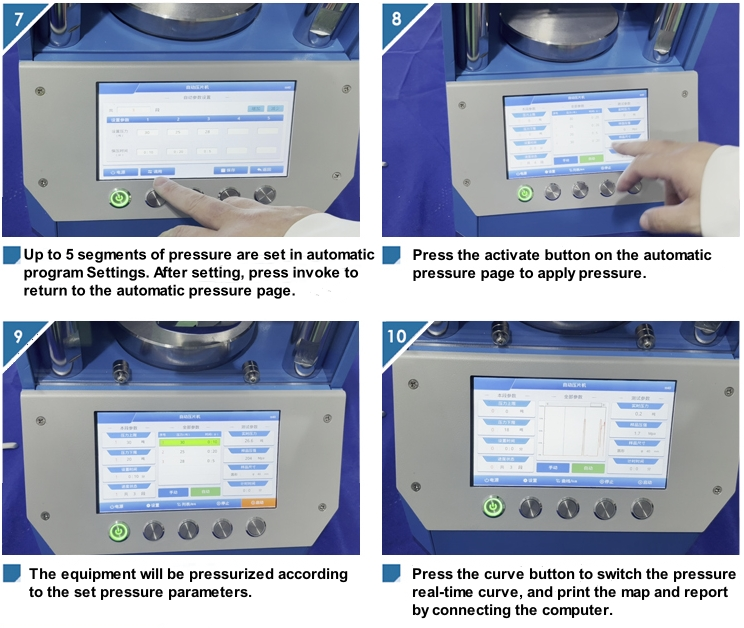

Operation interface (Automatic mode)

Activate button: Can be pressed according to the multi-stage pressurization program.

Stop button: During the pressurization process, you can stop the pressurization process.

List/Curve: The current display state can be switched between list and curve

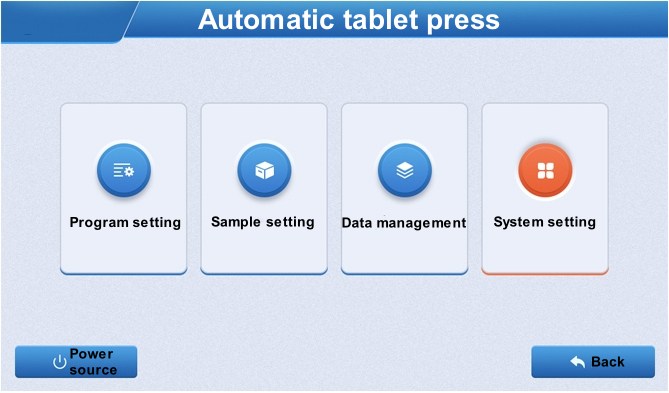

Setting interface

Tap Settings on the operation screen to enter the Settings screen. The Settings screen has four ICONS.

Program Settings: Multi-stage pressure program and pressure holding time can be set.

Sample setting: The shape and size of the sample can be set to facilitate the user to calculate the pressure of the sample.

Data management: Previously saved data records can be invoked and modified..

System Settings: Administrators can set various parameters, enter the password "666"

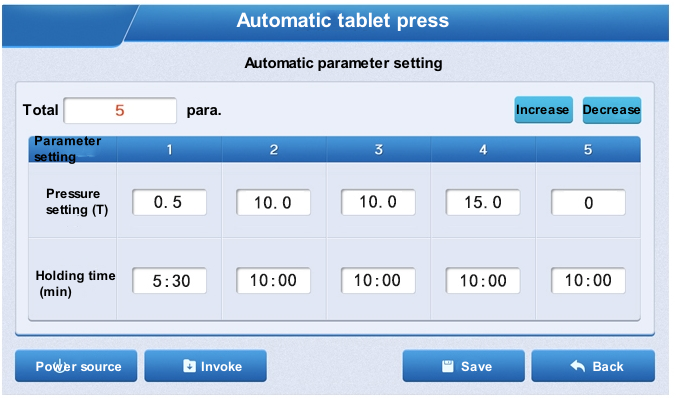

Setting interface

Multi-segment program Settings: Up to 5 segments of pressurized programs can be set.

Invoke button: Call the set parameters to the automatic operation interface for pressure.

Save button: Save the set parameters to the database for later invocation.

Back button: Returns to the Settings screen

Operation procedure

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588