products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Laboratory High Purity Iron Foam Fe Metal Foam Thickness Can be Customized

Model Number:

TMAX-Iron-Foam5Compliance:

CE CertifiedPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

1 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Laboratory High Purity Iron Foam Fe Metal Foam Thickness Can be Customized

Quantity Discount is Available: >5pcs, 15% OFF

Quantity Discount is Available: >10pcs, 25% OFF and Free Shipping

For more product information and ordering detail, please contact: David@tmaxcn.com

Introduction

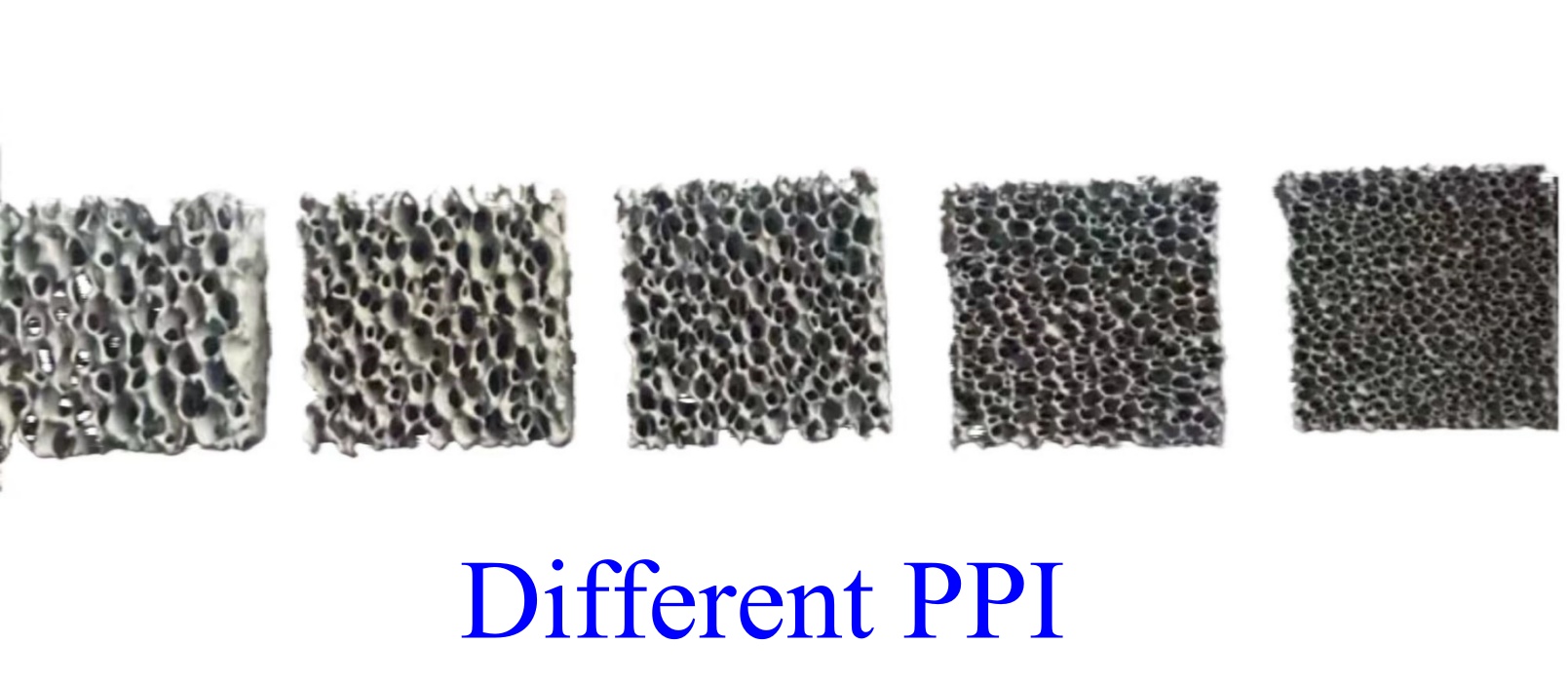

Iron foam containing the foamed pores has a higher porosity and a larger pore size of up to 10 mm than the generally sintered porous metal.

1. Sound absorption: porous structure has a wide frequency absorption characteristics.

2. Sound insulation: through additional treatment, a high noise can be intercepted, and the sound insulation effect is good.3. Electronic wave shielding: About 90dB electronic wave shielding.

4. Processability: it can cut, bend and simply stick.

5. Fire resistance: keep the shape stable, difficult to burn under high temperature, high temperature resistance.

6. Strong thermal conductivity.

7. It has good air permeability and filtration function, and the flow stability of gas and fluid is super strong.

8. High temperature resistance above 1100 ℃, uniform pore structure and fast heat transfer.

Specifications

| Item |

Producible specifications |

Reference specifications |

|

| PPI |

8-110(±2/5/10 ) |

110±10 |

13±2 |

| Surface density (g/m2) |

250-5000(±5% ) |

380±25 |

2000±100 |

| size ( mm) |

20-1000(±0.5/1.0/2.0 ) |

500±0.5 |

500±2 |

| Appearance |

Silver gray, without black spot, blind spot, through hole and crack |

||

| Chemical Composition |

Pure Iron |

(Fe):≤99.9% |

|

| (C):≤0.030% |

(S):≤0.008% |

||

| (Si):0.005% |

(Cu):≤0.005% |

||

To customize various metal foams, please click the picture below for details:

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588