products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

products

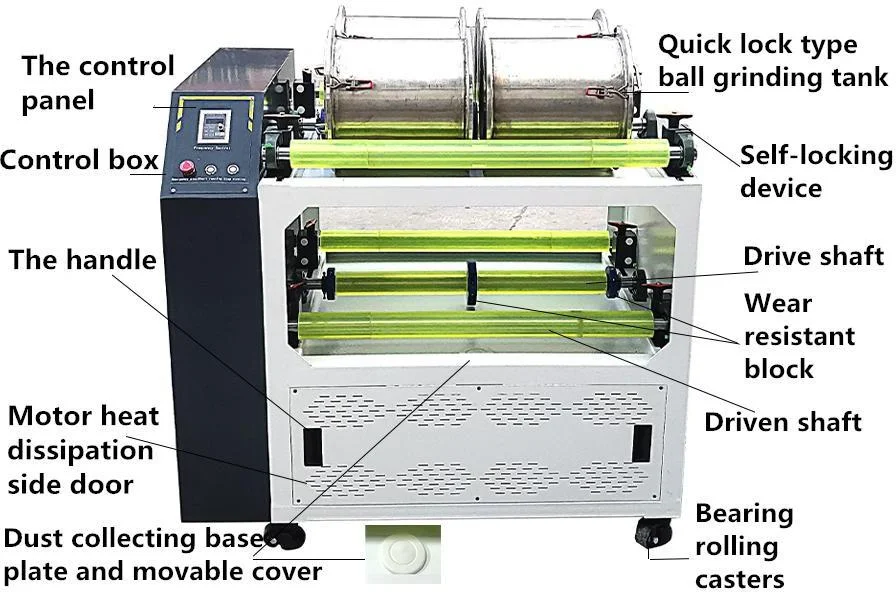

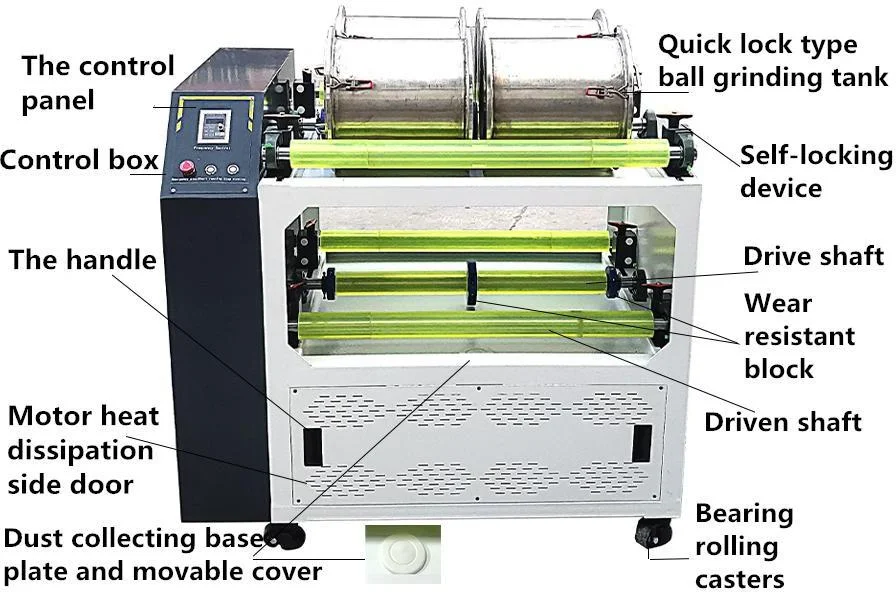

Lab Roller Jar Mill Machine with 8 Working Stations for Small Batch Material Grinding

Model Number:

TMAX-PM-8Input Power:

1.5KWDimension(L*W*H):

960*670*960mmNet Weight:

80KGCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technicalPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Laboratory Grinding Jar Rotating Roller Jar Mill with 2 Working Stations with Self-Locking DeviceNext:

Upgraded Lab Roll Ball Mill with Safety Cover

Product Details

Lab Roller Jar Mill Machine with 8 Working Stations for Small Batch Material Grinding

Features

Details show

Quick lock ball mill tank

Adopt this kind of fast lock fixed way, solve the trouble of lock screw, configure

portable hook device, convenient handling. You can also choose semi-automatic

lifting ball material separation system, fast lifting jars and handling balls material

separation.

The control panel

Frequency control, high precision speed, with under voltage, over current,

overload protection. Equipped with high-grade emergency stop and start button

with light.

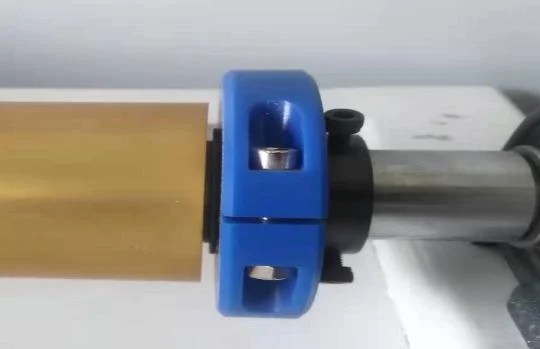

Self-locking device

Roller self-locking device (company patent), it is convenient to adjust the distance between

the rollers when using different jars, no tools are required to lock the screws, the bottom is

designed with rolling balls, the distance can be easily adjusted and fixed, the locking teeth

are up to 60MM, no need to worry about slipping come out.

Wearable objects

Wear resistant materials (polyurethane, rubber, etc.) are used for driving shaft

and driven shaft. Wear resistant and sliding materials are used for retaining

blocks to reduce friction coefficient.

The design of the movable stop well avoids the risk of the jars being worn left and right in

the running process.

Reasonable structural design, the distance between our rollers can be reduced to about 20

mm, suitable for some special customers to use their own vials for experiments.

Introduction

Tin ball mill works - root outsourcing wear-resisting rubber pieces of main shaft

by motor pulley connection do drive pulley, the outsourcing on the spindle

wear-resisting rubber pieces of relative motion between tanks, namely with ball

mill tank surface friction drive another root - driven shaft to realize rolling,

grinding medium and material of ball mill tank - up with the cylinder rotation

increases to a certain height, The material is crushed under the impact of the

grinding medium and the friction and shear caused by the rolling and sliding of

the grinding medium. The equipment has the advantages of novel appearance

design, simple structure and convenient use.

Use

Tank mill ball mill is a laboratory, small batch production with ultra-fine grinding,

mixing equipment. This machine is beautiful and novel, compact structure,

easy to operate, high efficiency, uniform grinding particle size, is the scientific

research, teaching, test, production of preferred equipment. It can be widely

used in electronic materials, magnetic materials, biological medicine, ceramic

glaze slurry, metal powder, non-metallic minerals, new materials and other

industries.

Characteristics

1. It can be used in single or multiple cans at the same time, and multiple

samples can be ground at the same time;

2. Timing, intermittent shutdown or continuous cycle operation;

3. The outer wear-resistant adhesive parts of the shaft are made of special

materials, which are durable;

4. Suitable for material fine grinding, crushing, mixing, material precipitation

prevention and other technological requirements, high efficiency

5. Can be customized according to customer requirements (multi-station

customization, multi-stage power output customization, etc.);

Name |

PM-8-5 |

PM-8-15 |

Overall dimension |

960*670*960 |

1130*800*960 |

Weight(kg) |

110KG |

150KG |

Specification |

Y1.5-4B3 |

Y2.2-4B3 |

Frequency Converter specification |

1.5KW/220V/single-phase |

2.2KW/380V/three-phase |

Roller speed(r/min) |

50-450 |

40-420 |

Maximum load per jar |

35KG |

80KG |

Hand gear/protective cover |

optional |

optional |

Image

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588