products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

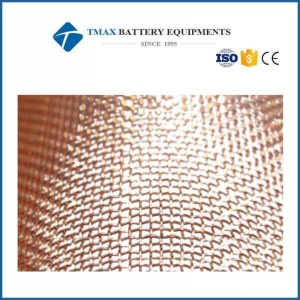

Copper Mesh Foil For Lithium Battery Anode Substrate 55um

Copper Mesh Foil For Lithium Battery Anode Substrate 55um

-

Copper Mesh Foil For Lithium Battery Anode Substrate

Copper Mesh Foil For Lithium Battery Anode Substrate

Advantage: Improve the consistency of battery usage group and reduce battery cost significantly. Improve the adhesion of active material and the collector, and reduce the electrode manufacturing cost. Reduce the polarization, increase the rate and capacity, improve the battery performance. Protection of fluid collection, extend battery life. Throughput: Possess Japan Fuji coating machine, slitting machine and automatic computer inspection rewinder machine. Average coating speed reach 90-120m/min. Product 21600m conductive coating aluminum foil every 8 hours,can be used for 200Kpcs 18650 core. Roller coating width up to 1 meters. Can adopt continuous or intermittent coating mode.

-

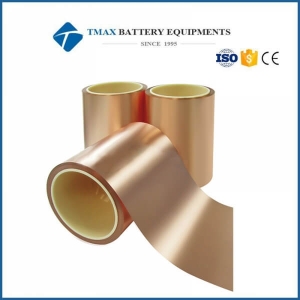

8/10/12 um Thickness Rolled Electrolytic Copper Foil For Lithium Battery

8/10/12 um Thickness Rolled Electrolytic Copper Foil For Lithium Battery

Advantage: Improve the consistency of battery usage group and reduce battery cost significantly. Improve the adhesion of active material and the collector, and reduce the electrode manufacturing cost. Reduce the polarization, increase the rate and capacity, improve the battery performance. Protection of fluid collection, extend battery life. Throughput: Possess Japan Fuji coating machine, slitting machine and automatic computer inspection rewinder machine. Average coating speed reach 90-120m/min. Product 21600m conductive coating aluminum foil every 8 hours,can be used for 200Kpcs 18650 core. Roller coating width up to 1 meters. Can adopt continuous or intermittent coating mode.

-

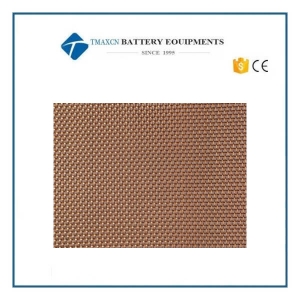

Stable Lithium Metal Anode with Metal Copper Mesh

Stable Lithium Metal Anode with Metal Copper Mesh

Advantage: Improve the consistency of battery usage group and reduce battery cost significantly. Improve the adhesion of active material and the collector, and reduce the electrode manufacturing cost. Reduce the polarization, increase the rate and capacity, improve the battery performance. Protection of fluid collection, extend battery life. Throughput: Possess Japan Fuji coating machine, slitting machine and automatic computer inspection rewinder machine. Average coating speed reach 90-120m/min. Product 21600m conductive coating aluminum foil every 8 hours,can be used for 200Kpcs 18650 core. Roller coating width up to 1 meters. Can adopt continuous or intermittent coating mode.

-

Copper Woven Mesh for Battery Electrode Preparation

Copper Woven Mesh for Battery Electrode Preparation

Advantage: Improve the consistency of battery usage group and reduce battery cost significantly. Improve the adhesion of active material and the collector, and reduce the electrode manufacturing cost. Reduce the polarization, increase the rate and capacity, improve the battery performance. Protection of fluid collection, extend battery life. Throughput: Possess Japan Fuji coating machine, slitting machine and automatic computer inspection rewinder machine. Average coating speed reach 90-120m/min. Product 21600m conductive coating aluminum foil every 8 hours,can be used for 200Kpcs 18650 core. Roller coating width up to 1 meters. Can adopt continuous or intermittent coating mode.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588