products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Pouch Cell Hot/Cold Press Machine for Battery Core Formation

Pouch Cell Hot/Cold Press Machine for Battery Core Formation

Lab Vacuum Sealing Machine for Preparing Pouch Cell With Optional Top/Side Sealing

-

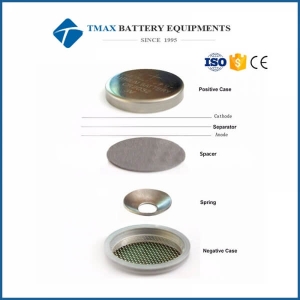

Lab Coin Cell Materials for Battery Research and Production

Lab Coin Cell Materials for Battery Research and Production

Related Material for Coin Cell Preparation No.1 Material 1 Ni foam,Cu foam,Ti foam ect 2 Al foil,Cu foil 3 Separator film 4 LiPF6 electrolyte,LiFePO4 electrolyte ect 5 PVDF powder,NCM powder ect 6 Lithium chip 7 Coin cell case,spring,spacer 8 Electrode Split Test Cell 9 E-mail: David@tmaxcn.com

-

Coin Cell Case with One Side Kapton Window for In-situ X- Ray Analysis

Coin Cell Case with One Side Kapton Window for In-situ X- Ray Analysis

-

Coin Cell Case Case with Two Sides Kapton Windows for In-situ Neutron Diffraction Analysis

Coin Cell Case Case with Two Sides Kapton Windows for In-situ Neutron Diffraction Analysis

-

Meshed CR2032 Coin Cells Cases (20d x 3.2mm) with Seal O-rings for Lithium Air Battery Research

Meshed CR2032 Coin Cells Cases (20d x 3.2mm) with Seal O-rings for Lithium Air Battery Research

-

Al-Clad CR2032 Coin Cell Case for Li-ion Battery

Al-Clad CR2032 Coin Cell Case for Li-ion Battery

-

Al-Clad CR2032 Coin Cell Case for Li-ion Battery

Al-Clad CR2032 Coin Cell Case for Li-ion Battery

-

Al-Clad Spring (Belleville Washers) for CR2032 Cases

Al-Clad Spring (Belleville Washers) for CR2032 Cases

-

Al-Clad Stainless Steel Wave Spring for CR2032/CR2016 Cases

Al-Clad Stainless Steel Wave Spring for CR2032/CR2016 Cases

-

5V100mA 8 Channel Battery Tester for Coin Cell Capacity Testing Coin Cell Cycler

5V100mA 8 Channel Battery Tester for Coin Cell Capacity Testing Coin Cell Cycler

constant-voltage source, which can be programmed and controlled by computer software. 2 This coin cell tester system provides most applications in battery testing fields such as electrode materials research, battery performance test, small scale battery formation, capability grading, battery pack testing, etc. 3 The coin cell tester is suitable for all kinds of coin cell battery such as lithium battery, NI-MH battery, Zn-Mn watch battery and so on.

-

Coin Cell Laboratory Pilot Fabrication Line

Coin Cell Laboratory Pilot Fabrication Line

Coin Cell Laboratory Pilot Fabrication Line No. Machine 1 Tube Furnace/Muffle Furnace 2 Planetary Ball Mill 3 Vacuum Mixer 4 Film Coater Machine 5 Roll Press Machine 6 Punching Machine 7 Vacuum Drying Oven 8 Glove Box Machine 9 Sealing Machine 10 Battery Tester Machine 11 E-mail: David@tmaxcn.com

-

CR2032 2025 Coin Cell Case with O-rings for Battery Research

CR2032 2025 Coin Cell Case with O-rings for Battery Research

1. We can supply various types 2. The surface is smooth, without burr. 3. Preferential price Packing: 100pcs /bag

-

Laboratory Assembly Line for Pouch Cell Preparation

Laboratory Assembly Line for Pouch Cell Preparation

-

3V CR2032 CR2032 CR2025 CR2016 CR1620 CR1632 CR2450 Lithium Button Coin Cell Li-MnO2 Battery

3V CR2032 CR2032 CR2025 CR2016 CR1620 CR1632 CR2450 Lithium Button Coin Cell Li-MnO2 Battery

-

Model Coin Cell Swelling System Tester Machine For Laboratory R&D

Model Coin Cell Swelling System Tester Machine For Laboratory R&D

Model Coin Cell Swelling System Tester Machine For Laboratory R&D Introduction As a popular energy storage carrier, lithium-ion battery (LIB) has been widely used in our daily life. With the increase of the application scenarios, the safety of the LIBs receives higher requirements. The charging and discharging processes of the LIBs are usually accompanied by the structure expansion with different degrees. On the one hand, the structure expansion will affect the assembly space of the LIBs, on the other hand, the accumulation of the side reactions caused by the irreversible expansion will also lead to the structural destruction of the active material and accelerate the capacity fading. For a single cell, there are several methods for characterizing its expansion performance, such as applying a certain pressure on the surface of a single cell, and testing the expansion force or the expansion thickness of the cell. However, the expansion parameters measured by all these methods include the expansion of multiple positive and negative electrodes, separators and aluminum plastic film or aluminum shell, which cannot accurately analyze the expansion property of a material. Scheme of Model Coin Cell Main features: 1.The instrument size is small (length * width * height 120 * 150 * 280mm), which can be placed in the glove box; 2.The model coin cell can be used to assemble various types of full coin cell; 3.Good tightness can ensure long-term test stability and obtain more reliable test results; 4.High-precision thickness measurement system, thickness measurement resolution 0.1µm, precision ± 1 µm. 5.In-situ test of the full-cell expansion thickness curve; 6.Ion conductivity of the solid electrolyte can be measured; 7.The software can automatically combine the thickness change of the model coin cell with the charging and discharge data (compatible with partial charging and discharge tester), and output the report involving all testing data. Application case 1.NCM-Graphite Full Coin Cell: Assemble the NCM-Graphite LIB to test the thickness change during charge and discharge; test parameters: the current density is 0.6mA / cm2,2.8~4.2V; The thickness of the battery decreases in the first charing process, which is mainly due to the rest stage after assembly. Under a certain pressure condition, the interface contact between the positive and negative electrodes will gradually get close, so it is necessary to rest as far as possible (usually for more than 3h) before start to measure the thickness expansion during the charging process; The thickness change of both charging and discharge processes was about 1.33 μm/mAh, along with a corresponding volume change of 0.2 mm3/mAh, which is mainly caused by the deintercalation of the lithium ions from the graphite. The thickness of the graphite coating is about 100 μm. If ignore the expansion effect of the positive electrode, the percentage of the thickness change of graphite is about 2%. 2.NCM-Si / C Full Coin Cell: Assemble NCM-Si / C LIB and test the thickness change during charge and discharge; test parameters: current density is 0.6mA / cm2,3~4.3V; Ignore the expansion of NCM positive electrode, and the total expansion thickness measured from the model coin cell mainly comes from the expansion of the SiC negative electrode during the expansion experiment. By further deducting the thickness of the copper current collector, the thickness expansion ratio can be calculated; Compared with two kinds of materials, expansion ratio of A material is greater than that of B material. The expansion ratios of these two materials at the first charging process are similar. During the subsequent cycling, the maximum expansion thickness of B material will decrease compared to the first cycle, and shows increase gradually during the cycling. However, for the A material, the maximum expansion thickness of each cycle increase continuously. These different expansion behaviors between these two materials are due to the different modification ways. 3.The L i-L i Symmetric Cell: Assemble Li-Li symmetric cell to test the thickness change during lithium deposition; test parameters: current density is 0.5mA / cm2, charing and discharging for 2h and rest for 5min; During the lithium deposition, the total thickness of the cell gradually increased. Every 2 mAh of the lithium deposition will cause the increase of the thickness of about 2 μm, corresponding to the volume expansion of about 0.76 mm3/mAh 4. NCM-Li half battery: Assemble the NCM-Li half cell to test the thickness change during charing and discharging; test parameters: the current density is 0.6mA / cm2,3~4.3V; During the charging process, the thickness expansion is about 4 μm/mAh, and the volume expansion is about (0.6 mm3/mAh), which is mainly caused by the lithium plating at the surface of the lithium metal anode; During the discharging process, the thickness shrinkage is about 3 μm/mAh, and the volume shrinkage is about (0.5mm3/mAh), which is mainly due to the decrease of the thickness of the lithium metal anode caused by the continuous deintercalation of the lithium ions from the lithium metal anode. Model Model MCS1000 MCS1400 Number of channels Single channel Four channel Main parameters Thickness measurement range 0-10mm Thickness resolution 0.1um Thickness measurement accuracy ±1um Mold size Inner diameter 13mm, 16mm, 20mm (other diameters available) Installation conditions Power supply 220-240V/50-60Hz Voltage change tolerance ±10% Power consumption 30W Net weight 10kg Instrument size 120*150*280 mm

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588