Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

Supercapacitors, also known as ultracapacitors or electrochemical capacitors, are energy storage devices characterized by their high power density, rapid charge and discharge capabilities, and long cycle life. The production of supercapacitors involves several sophisticated processes and specialized machinery to ensure high performance and reliability. This article provides a detailed overview of the supercapacitor

production machine, its components, functions, advantages, and challenges.

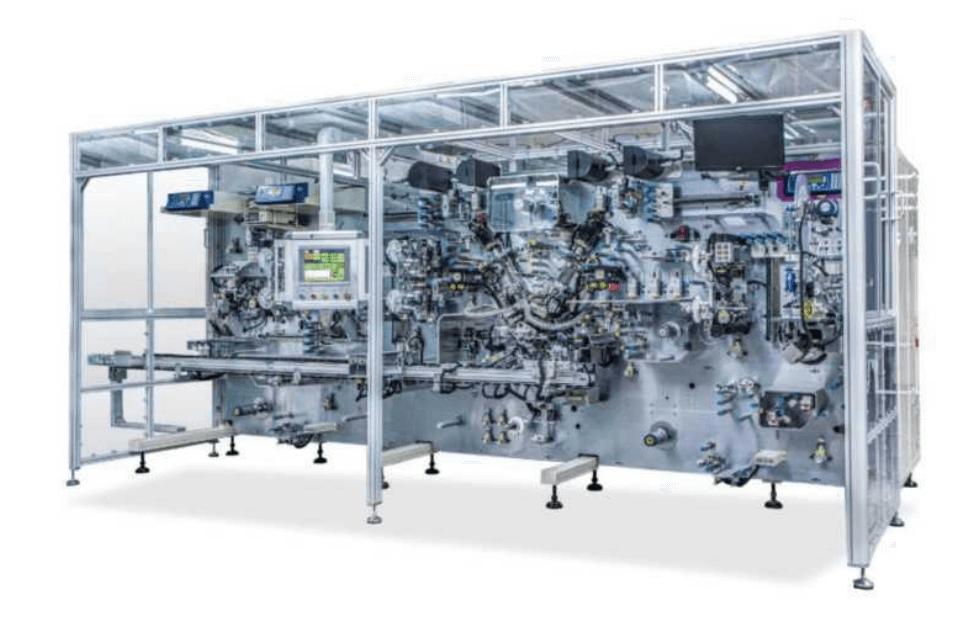

Key Components of a Supercapacitor Assembly machine

1.Mixing and Dispersion Equipment

Purpose: To prepare the electrode slurry by mixing active materials (e.g., activated carbon), binders, and conductive additives with a solvent.

Equipment: High-shear mixers, planetary mixers, and ultrasonic dispersers.

2.Coating Machine

Purpose: To apply a uniform layer of electrode slurry onto current collectors (typically aluminum or copper foil).

Equipment: Slot-die coaters, doctor blade coaters, and gravure coaters.

3.Drying Oven

Purpose: To evaporate the solvent from the coated electrodes, leaving a solid layer of active material.Equipment: Conveyor belt ovens, tunnel dryers, and vacuum ovens.

Purpose: To compress the coated electrodes to achieve the desired thickness and density, enhancing electrical conductivity and mechanical integrity.

Equipment: Precision rollers with adjustable pressure settings.

Purpose: To cut the dried and calendered electrodes into specific sizes suitable for assembly.

Equipment: Laser cutters, mechanical shears, and die cutters.

Purpose: To assemble the electrodes and separators into a wound or stacked configuration, depending on the supercapacitor design.

Equipment: Automatic winding machines for cylindrical cells, stacking machines for prismatic and pouch cells.

7.Electrolyte Filling Machine

Purpose: To inject electrolyte into the assembled supercapacitor cells, ensuring complete wetting of the electrodes.Equipment: Precision filling machines with controlled dispensing systems.

8.Sealing Machine

Purpose: To hermetically seal the supercapacitor cells, preventing electrolyte leakage and contamination.Equipment: Heat sealers, laser welders, and crimping machines.

9.Formation and Aging Equipment

Purpose: To perform initial charge-discharge cycles to stabilize the electrochemical properties of the supercapacitors.Equipment: Formation stations with programmable charge-discharge cycles, aging racks.

10.Testing and Quality Control Equipment

Purpose: To test the electrical performance, safety, and reliability of the supercapacitors.Equipment: Impedance analyzers, leakage current testers, capacitance measurement devices, environmental chambers for stress testing.

Supercapacitor Production Process

Mixing: The active materials, binders, and conductive additives are mixed with a solvent to form a homogeneous slurry.

Dispersion: Ensures uniform distribution of particles in the slurry to prevent agglomeration.

Application: The slurry is uniformly coated onto current collector foils.

Drying: The coated foils are passed through drying ovens to remove the solvent.

Compression: The dried electrodes are compressed to achieve the desired density and thickness, improving electrical contact and mechanical stability.

Precision Cutting: The electrodes are cut into specific shapes and sizes, ensuring uniformity for assembly.

Winding/Stacking: The electrodes and separators are assembled into the desired configuration.

Electrolyte Filling: The cells are filled with electrolyte, ensuring thorough wetting of the electrodes.

Hermetic Sealing: The cells are sealed to prevent leakage and contamination.

Initial Cycling: The cells undergo initial charge-discharge cycles to stabilize their electrochemical properties.

Aging: Cells are aged under controlled conditions to ensure performance stability.

Electrical Testing: Capacitance, resistance, and leakage current are measured.

Safety Testing: Cells are tested for mechanical integrity and thermal stability.

1.High Precision: Ensures uniform coating, cutting, and assembly for consistent performance.

2.Scalability: Machines can be scaled up for mass production, meeting industrial demands.

3.Automation: Reduces manual labor and increases production efficiency.

4.Quality Control: Integrated testing equipment ensures high reliability and safety of the final products.

1.Material Handling: Ensuring uniform dispersion and preventing agglomeration of active materials in the slurry.

2.Coating Uniformity: Achieving a consistent and defect-free coating layer on the current collectors.

3.Electrolyte Handling: Ensuring complete wetting of electrodes without overfilling or contamination.

4.Sealing Integrity: Achieving a hermetic seal to prevent electrolyte leakage and enhance longevity.

5.Cost Management: Balancing high precision and quality with cost-effective production methods.

Development Challenges

1.Material Innovations: Developing new materials with higher capacitance, better stability, and lower cost.2.Process Optimization: Enhancing production processes to increase efficiency and reduce waste.

3.Environmental Impact: Developing eco-friendly materials and processes to minimize environmental impact.

4.Automation and AI: Integrating advanced automation and AI for real-time monitoring and optimization of the production process.

Conclusion

The production of supercapacitors involves sophisticated machinery and precise control over multiple processes to ensure high performance and reliability. From slurry preparation and electrode coating to cell assembly and quality control, each step is crucial for the final product's success. While challenges related to material handling, coating uniformity, and sealing integrity exist, continuous advancements in technology and process optimization are driving the evolution of supercapacitor production. As demand for high-performance energy storage solutions grows, the role of advanced production machines will become increasingly important in meeting industry needs.

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588