Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

Setting up a battery assembly plant involves numerous steps, from initial planning and design to procurement of equipment, installation, and commissioning. This guide provides an overview of the essential stages and considerations involved in establishing a battery assembly plant.

1. Planning and Feasibility Study

Market Analysis

Demand Forecast: Assess the market demand for batteries, including the types of batteries (e.g., lithium-ion, lead-acid, nickel-metal hydride) and their applications (e.g., electric vehicles, consumer electronics, energy storage systems).

Competition Analysis: Identify key competitors and analyze their production capacities, market share, and technology.

Financial Planning

Investment Estimation: Estimate the total investment required, including land, building, machinery, and working capital.

Funding Sources: Identify potential funding sources, such as loans, investors, or government grants.

Site Selection

Location: Choose a strategic location considering factors like proximity to raw material suppliers, target markets, and transportation facilities.

Infrastructure: Ensure the site has access to necessary utilities such as electricity, water, and gas, as well as waste disposal facilities.

2. Plant Design and Layout

Design Requirements

Production Capacity: Determine the plant's production capacity based on market demand and scalability.

Space Planning: Design the layout to optimize the workflow, ensuring efficient movement of materials and personnel.

Layout Planning

Raw Material Storage: Allocate space for storing raw materials such as electrodes, electrolytes, separators, and casings.

Production Lines: Design separate production lines for electrode preparation, cell assembly, electrolyte filling, sealing, and formation.

Quality Control: Set up laboratories and testing areas for quality control and R&D.

Finished Goods Storage: Allocate space for storing finished batteries before shipment.

3. Equipment Procurement for Battery Assembly Plant

Procuring the right equipment is critical for the efficiency, quality, and scalability of a battery assembly plant. This section details the types of equipment required, considerations for selecting vendors, and tips for ensuring the best procurement process.

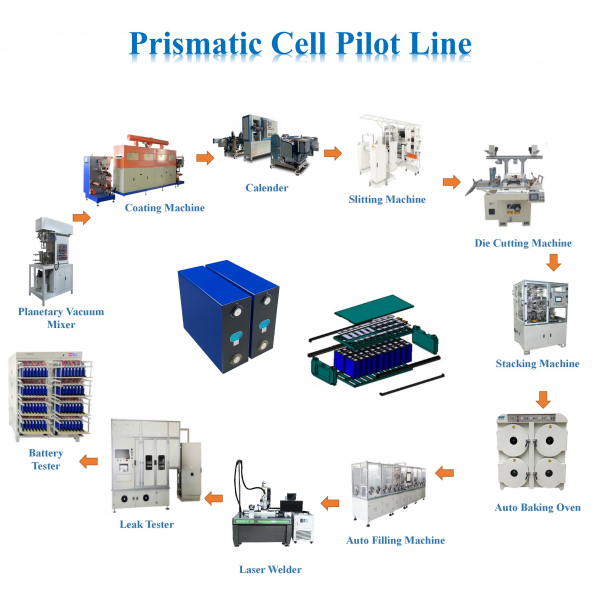

Key Equipment for Battery Assembly Plant

Electrode Preparation Equipment

Mixers: Used for preparing electrode slurry by mixing active materials, binders, and solvents. High-shear mixers ensure uniform consistency.

Coating Machines: Apply the electrode slurry onto current collectors (aluminum for cathode, copper for anode). Precise control over thickness and uniformity is essential.

Battery Calendering Machine: Compress coated electrodes to achieve desired thickness and density, improving electrochemical performance.

Slitting Machines: Cut the dried and calendered electrodes into precise widths and lengths for further processing.

Cell Assembly Equipment

Cutting Machines: For precisely cutting separators to match electrode dimensions.

Stacking/Winding Machines: Assemble the electrodes and separators into stacks (pouch and prismatic cells) or wound structures (cylindrical cells). Automation ensures consistency and precision.

Tab Welding Machines: Weld current collector tabs to electrodes. Ultrasonic or laser welding is commonly used for strong, reliable connections.

Electrolyte Filling Machines: Inject electrolyte into assembled cells. Precision filling is crucial to ensure proper cell performance and safety.

Sealing Machines: Seal the cells using methods like heat sealing, ultrasonic sealing, or laser welding, depending on the cell type (pouch, cylindrical, prismatic).

Formation and Testing Equipment

Formation Equipment: Perform initial charge/discharge cycles to form the solid electrolyte interface (SEI) on the anode and stabilize cell performance.

Cyclers and Testers: Test cells for capacity, voltage, internal resistance, and other key performance metrics. Automated systems can handle large volumes of cells.

Environmental Chambers: Simulate various operating conditions (temperature, humidity) to test cell performance and durability.

Safety and Environmental Equipment

Fume Hoods and Scrubbers: Control emissions from solvents and chemicals used in electrode preparation and cell assembly.

Waste Management Systems: Handle and dispose of hazardous waste materials safely and in compliance with regulations.

Vendor Selection

Reputation and Experience

Choose vendors with a proven track record in the battery manufacturing industry.

Check references and case studies of previous installations to ensure reliability and performance.

Technical Support and Training

Ensure vendors provide comprehensive training for operating and maintaining equipment.

Opt for suppliers who offer robust after-sales support, including spare parts availability and technical assistance.

Customization and Flexibility

Vendors should be willing to customize equipment to meet specific production requirements.

Equipment should be adaptable to future changes in battery technology and production processes.

Quality and Certification

Ensure equipment meets industry standards and certifications (e.g., CE, ISO).

Conduct factory acceptance tests (FAT) and site acceptance tests (SAT) to verify equipment performance before final acceptance.

4. Installation and Commissioning

Installation

Site Preparation: Prepare the site by constructing necessary buildings and infrastructure.

Equipment Installation: Install machinery according to the layout plan, ensuring proper alignment and calibration.

Commissioning

System Integration: Integrate all systems, including production lines, quality control, and safety systems.

Trial Runs: Conduct trial runs to ensure all equipment operates correctly and the production process flows smoothly.

5. Staffing and Training

Recruitment

Skilled Labor: Hire skilled labor for operating machinery, quality control, and maintenance.

Management: Employ experienced management personnel to oversee operations, logistics, and administration.

Training

Technical Training: Provide technical training for staff on operating and maintaining equipment.

Safety Training: Conduct safety training to ensure compliance with health and safety regulations.

6. Quality Control and Assurance

Quality Management System

Standards Compliance: Implement quality management systems that comply with relevant industry standards (e.g., ISO 9001).

Testing Protocols: Develop rigorous testing protocols for raw materials, in-process materials, and finished products.

Continuous Improvement

Feedback Loop: Establish a feedback loop to continuously improve production processes based on quality control data and customer feedback.

7. Environmental and Safety Considerations

Environmental Compliance

Waste Management: Implement waste management systems for safe disposal of hazardous materials and recycling of production waste.

Emission Control: Install emission control systems to minimize environmental impact.

Safety Measures

Protective Equipment: Provide protective equipment for workers handling hazardous materials.

Safety Protocols: Develop and enforce safety protocols to prevent accidents and ensure a safe working environment.

8. Production and Scaling

Initial Production

Pilot Production: Start with pilot production runs to fine-tune processes and ensure product quality.

Full-Scale Production: Gradually ramp up to full-scale production once the processes are optimized and stable.

Scaling Up

Capacity Expansion: Plan for future capacity expansion based on market demand and business growth.

Process Optimization: Continuously optimize production processes to improve efficiency and reduce costs.

Conclusion

Setting up a battery assembly plant requires meticulous planning, significant investment, and careful execution. By following the outlined steps and considering key factors such as market analysis, plant design, equipment procurement, and quality control, businesses can successfully establish a battery assembly plant that meets market demands and adheres to industry standards. Ongoing improvements and scalability considerations will ensure the plant remains competitive and capable of meeting future technological advancements and market needs.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com