products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Beeswax Wrapper Coating Machine Cotton Fabric Coater

Model Number:

SIMY-BWCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Comma Blade & Gravure Roll Dual Coating Heads Multifunctional Coating MachineNext:

Customizable Teeth Whitening Strips Coating Equipment Dental Stickers Coater

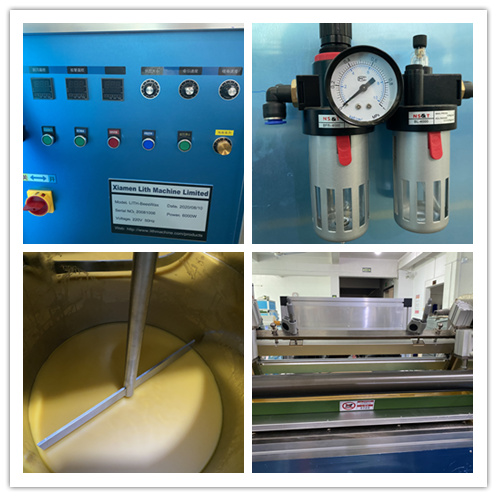

Beeswax Wrapper Coating Machine Cotton Fabric Coater

Functional description and technological process

1.1 Function description: This coater coats cotton fabric with beeswax oil, etc., and forms environmentally friendly packaging wrappers after curing in a drying oven.

1.2 Equipment technological process

1.2.1. Unwinding of coated substrate (tension control)→→Manual stop, cutting and reloading→→Drawing before coating→→Comma blade coating→→Reserved thickness measurement installation location→→ guide roller oven →→Deviation deviation at the oven exit→→Laminating unit→→Drawer roll discharge

1.2.2. Compound unwinding (overall edge correction)→→Manual cutting and replacement→→Laminating unit

1.2.3. Laminating unit →→Rewinding and cutting piece (optional)

Specification Parameters

Control system |

self-developed PLC touch screen |

Coating width |

100-1000mm (customizable) |

Coating method |

Doctor blade |

Drying method |

Air-cooled dry |

Cooling oven length |

|

Temperature |

normal temperature ~120 degrees |

Coating speed |

0-5 meters/min (customizable) |

Tension control |

Automatic tension |

Winding device |

Automatic winding |

Cutter(optional) |

Flat cutter |

Heated cylinder |

30L |

Power supply |

220V, 50/60Hz, 5000-8000W |

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588