products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

Energy Storage Type Graphene Powder For Graphene Super Capacitor Materials

Energy Storage Type Graphene Powder For Graphene Super Capacitor Materials

Energy Storage Type Graphene Powder For Graphene Super Capacitor Materials Packing:10g/bag Mode: TMAX-G4530 Model Standard value specific area(m2/g) particle-size analysis purity(%) water(%) ash content(%) aperture (nm) PH D10/(um) D50/(um) D90/(um) TOB4532 ≥2000 ≤20 ≤50 ≤80 ≥99 ≤0.5 ≤0.5 1~10 8.0~9.0 Performance: With high specific surface area and advanced pore, The pore structure is reasonable, Compared with the conductive properties of activated carbon is better, can effectively reduce the internal resistance, improve the cycle life. Application: Can be used as electrode material for supercapacitor. Mainly used in electric vehicles, electric tools, railway system, electric power, wind power system... Handling and storage Operators should be trained, strictly abide by the rules.Proposed operators wear appropriate protective clothing,wear suitable chemical protective gloves, avoid breathing, avoid direct contact with eyes and skin. and number of fire equipment and emergency treatment equipment. Store in a cool, ventilated and dry place. Keep the container sealed. Away from fire, heat source. With the strong oxidation agent separate storage. Storage area is equipped with the appropriate variety and quantity of fire fighting equipment, emergency treatment equipment and appropriate container materials.

-

Enhancement Type Graphene Powder For Composites

Enhancement Type Graphene Powder For Composites

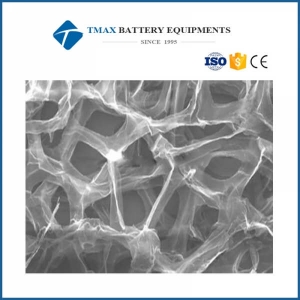

Enhancement Type Graphene Powder For Composites Specifications graphene powder for composites 1.High quality 2.High stability 3.High purity Item Unit Standard T- G1 T- G2 T- G3 Specific area (BET) m2/g 200~300 100~250 50~250 Stacking density g/cm3 0.005~0.01 0.04~0.07 0.07~0.1 PH 3~4 6 ~7 6~7 Grain size (D50) um 5 ~ 50 Carbon element % 68~80 68~80 ≥92 O % 20~28 20~28 ≤5 S % ≤1.0 ≤1.0 ≤1.0 Conductivity S/m ~800 ~800 ~1500 The performance and the application This series of products can be covalent and non covalent functionalization, so it can be widely used in composite materials, optoelectronic materials and devices and biomedicine fields. This series of products with a thickness of 1~20nm, chip size is 1~50 um, stably dispersed in various organic solvents in the high-speed stirring or ultrasonic conditions, with high specific surface area and higher thermal conductivity properties,thus can improve the material corrosion and high temperature characteristics, can be used as conductive agent(plastic, coating, rubber), antistatic material, electrode material (chemical power source, sensors, solar cells, fuel cells) and catalyst carrier etc.. Product packaging, storage and transportation 1. Packaging: plastic bottles, plastic bags or bottled 2. Storage: This product should avoid light sealed in a dry environment, and the temperature is not higher than 35°C. With no toxic and harmful gases, volatile matter and pollution source contact. Keep away from fire. 3.transportation: in the process of transportation, avoid sunlight and damp, prohibition and hard mixed, forbid throwing, light light unloading. Safety precautions Need to wear proof mask the use of the process, to avoid direct contact with the skin.

-

Graphene Oxide Powder For Graphene Battery Raw Material

Graphene Oxide Powder For Graphene Battery Raw Material

High Quality Graphene Oxide Powder For Graphene Battery Raw Material Specifications graphene oxide 1.High quality 2.High stability 3.High conductivity

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588