products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Winding Machine for Supercapacitor and Cylindrical Cell Production Line

Model Number:

TMAX- ZQR60Input Power:

1kwDimension(L*W*H):

2000x1200x1500mmCompliance:

CE CertifiedWarranty:

1 yearMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic 2 in 1 Ultrasonic Tab Welding Machine for Battery Production LineNext:

Pouch Cell Automatic Layer by Layer Stacker Stacking Machine

Automatic Winding Machine for Supercapacitor and Cylindrical Cell Production Line

SPECIFICATIONS:

1 This machine is full automatic winding machine used for Capacitor and Cylinder Battery Winding machine.

2 The total winding process is full automatically.

1) Finished battery core outside diameter :D=φ25-φ70mm with tolerance ±0.8%.

2) Winding blade diameter :φ8-φ20mm(standard d = φ8 mm)

3) Winding length :1000-6000mm

4) Finished battery core height :b=100–170mm

5) Termination of the protective tape : 1.1-2cycle, adjustable, stick position adjustable, Overlapping length :50-360 mm

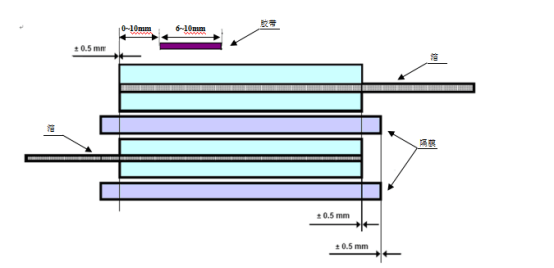

6) Finished battery core Degree of edge alignment as following

7)Winding mode as following

Technological process:

Separator feeding→Stop the feeding of tape and protective tape→Feeding of positive and negative plates→Detection of positive and negative foils→Pole group winding

→Length control→Stick the termination tape and protective tape→Final diameter monitoring→Chamfering→Through hole→Short circuit test→Good product discrimination

For materials:

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588