products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

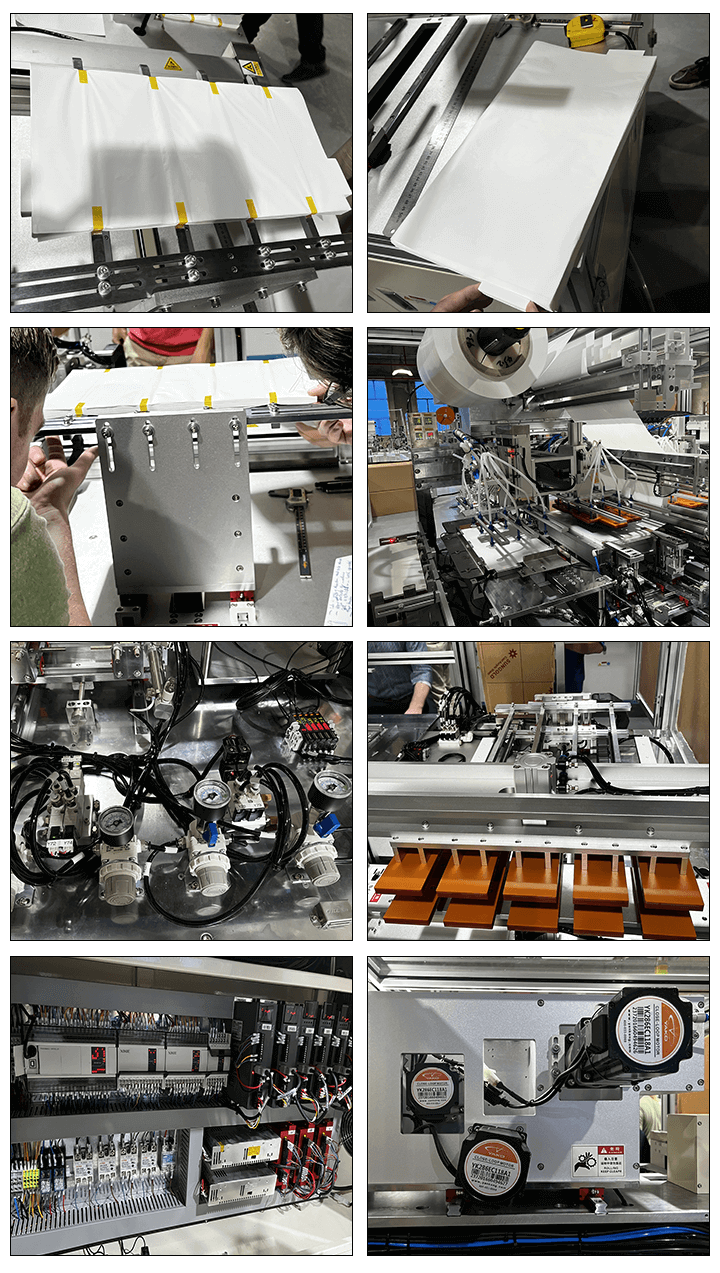

Automatic Stacking Machine For Lithium Battery Stacking Process

Model Number:

TMAX-A-007Compliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

U type sticking film machineNext:

Automatic Lithium Battery Electrode Die Cutting Machine for Pouch Cell

Automatic Stacking Machine For Lithium Battery Stacking Process

Functions

● This equipment is suitable for the lithium-ion battery batteries of anode and

cathode Z with isolation membrane laminated assembly, automatic outsourcing

isolation membrane in the polar group, automatic cutting off the diaphragm,

automatically terminate locking adhesive tape, automatic blanking, manual

collect batteries.

Features

● Anode and cathode are single configuration manger, the trough’s sheet with real-time lifting structure;

● Slight bend, brush, shaking and flexible sucker can

effectively prevent the multi-plate absorption phenomenon;

● Secondary precise positioning, ensure the plate

alignment degree;

● Equipment dust removal device, can focus the dust

collector chipped, ensure mechanical mesa clean;

● Anode and cathode pressure claw cathode film, prevent

cross contamination phenomenon;

● solation membrane ion wind blow dry, remove the

isolation membrane electrostatic;

● Secondary positioning installation of ultrasonic

sensor to detect repeat or lack of pills;

● Adopts servo drive lamination machine, can make the

stress between the layers of sheet was evenly;

● Imported non-trace buffer sucker, effective to

prevent the occurrence of suction plate printing, indentation phenomenon;

● With functions of diaphragm recycling and the first piece of diaphragm correction function.

repeatable and precise electrode stacking.

Technical Parameters(for reference):

| ITEM |

HBZDP150 |

HBZDP250 |

HBZDP300 |

| Measure |

1800*1600*1950mm (L*W*H) |

1920*1850*1950mm (L*W*H) |

2100*1850*1950mm (L*W*H) |

| weight |

About 1.0 T |

About 1.2 T |

About 1.3 T |

| power |

AC220V/50HZ, 3.0kw |

AC220V/50HZ, 3.0kw |

AC220V/50HZ, 3.0kw |

| Air source |

>0.6Mpa,30L/min |

>0.6Mpa,30L/min |

>0.6Mpa,30L/min |

| Vacuum source |

≤-0.09Mpa,15L/s |

≤-0.09Mpa,15L/s |

≤-0.09Mpa,15L/s |

| Applicable range |

L:50-150mm,W: 35-90mm,T:5-30mm |

L:100-250mm,W: 60-150mm,T:5-50mm |

L:150-300mm,W:100-200mm,T:5-50mm |

| Capacity |

1.1-1.4s/plate |

1.2-1.6s/plate |

1.3-1.7s/plate |

| Action |

>99% |

>99% |

>99% |

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588