products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

products

Automatic Cutting Machine for Casing Wires Electronic Wire Teflon Wire PVC Wires Silicone Line Casing

Model Number:

TMAX-HZX-220TSDimension(L*W*H):

450*720*360mmNet Weight:

45KGCompliance:

CE CertifiedWarranty:

One year limited warranty and lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Cutting Machine for Belt Electronic Wire Teflon Wire PVC Wires Nylon BeltNext:

Automatic Cutting Machine for PVC Wires Electronic Wire Teflon Wire Silicone Line Casing Wires

Product Details

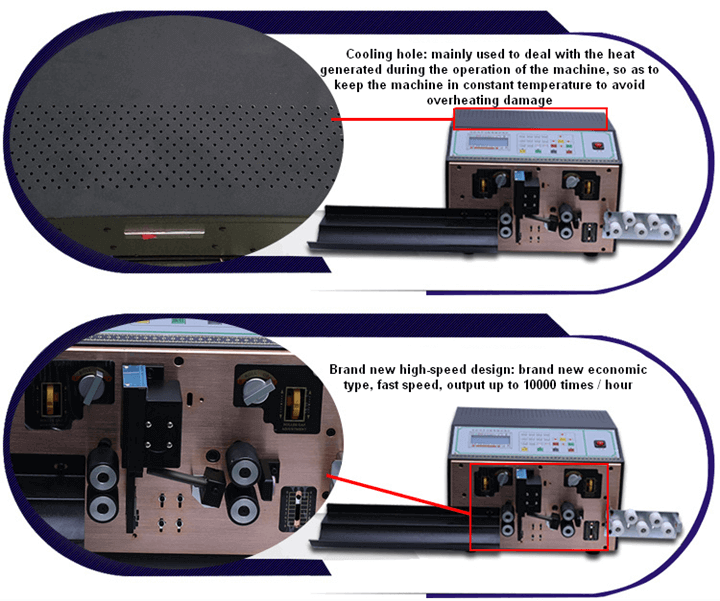

Automatic Cutting Machine for Electronic Wire Teflon Wire PVC Wires

Features :

TMAX-HZX-200 has the function of stripping and cutting, and the function of twisting is added to HZX-220TS. The machine is suitable for stripping, intermediate stripping and twisting of electronic wires, casing wires, silicone wires, Teflon wires, glass fiber wires, isolation wires, silica gel wires, coaxial lines, PVC wires, etc. HZX-220TS also enhanced the design of ultra short line.

Peeling range: electronic wire, silicon line, glass fiber line, isolated line, PVC line,coaxial line, casing etc.

Function : Short linear design , leaving the middle plastic 14mm ends twisted wire stripping.

Specification:

Model |

HZX-220TS |

Dimensions |

450mm*720mm*360mm |

Weight |

45kg |

Voltage |

AV110V/220V |

Power |

0.22kw |

Cutting length |

0.1 -6000mm |

Simultaneously |

2pcs(more can be customized, such as cutting 3 / 4 at the same time) |

Stripping length |

0.1-99mm (Depending on the material)Determined on wire materials |

Stripping speed |

2000-6000PCS |

Accuracy |

0.002*Lmm |

Applicable wire |

AWG#12-AWG#32 |

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588