products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

60T Double Plate Manual Hot Press with Manual And Automatic Operation Interface

Model Number:

TMAX-PCH-600D1/DG1Compliance:

CE CertifiedWarranty:

One year limited standard warrantyMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab High Temperature Manual Vacuum Hot Press Machine of 10T PressureNext:

Piston Diameter 95mm Lab Manual Hydraulic Press with Four Columns

60T Double Plate Manual Hot Press with Manual And Automatic Operation Interface

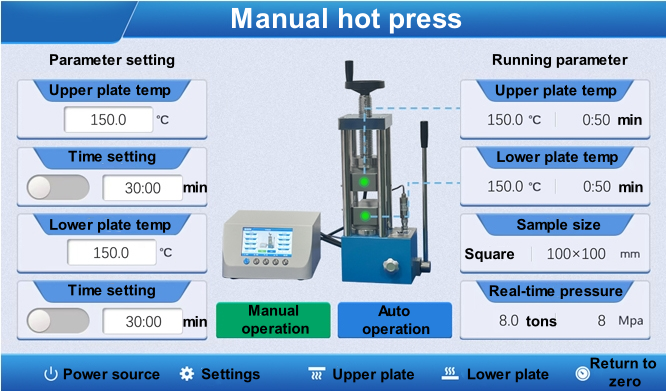

Operation interface (Manual mode)

a. Manual interface: The upper and lower plate heating temperature and constant temperature time can be set separately on this interface.

b. Reset button: Calibrates the pressure to zero.

c. Upper plate button: Heat the upper heating plate.

d. Lower plate button: heat the lower heating plate.

e. Timing switch: The timing function can be turned on and off.

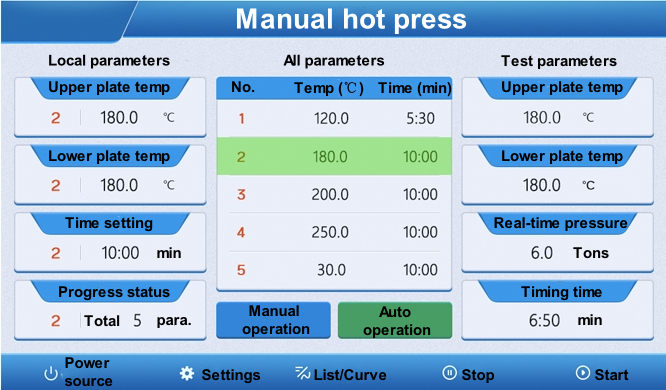

Operation interface (Automatic mode)

a. Start button: You can press the multi-stage heating program to heat up.

b. Stop button: During the heating process, you can stop the heating process.

c. List curve: You can switch the current display state, list and graph.

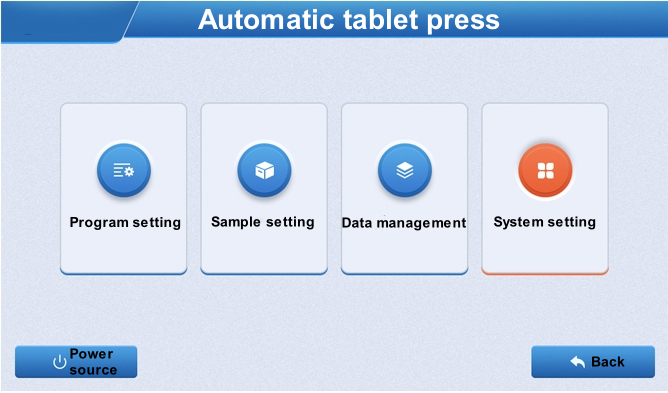

Setting interface

a. Tap Settings on the operation screen to enter the Settings screen. The Settings screen has four ICONS.

b. Program Settings: you can set up multiple pressure procedures and pressure holding time.

c. Sample setting: The shape and size of the sample can be set to facilitate the user to calculate the pressure of the sample.

d. Data management: Calls can be made to modify previously saved data records.

e. System Settings: Administrators can set various parameters, enter the password "666"

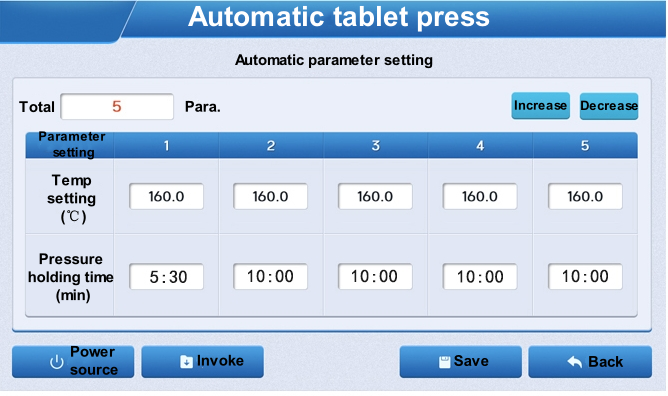

Setting interface

a. Multi-segment program setting, you can set the heating program within 5 segments.

b. Invoke button, you can invoke the set parameters, to the automatic operation interface, heating.

c. Save button, you can save the set parameters to the database, easy to call later.

d. Back button to return to the setting screen.

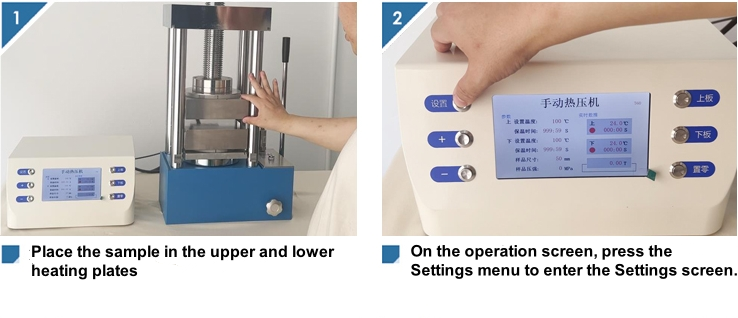

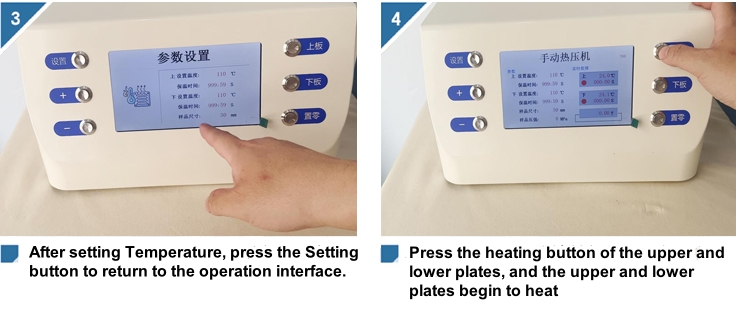

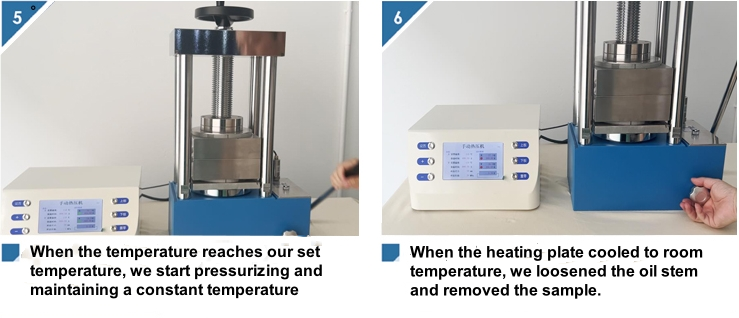

Operation procedure

Technical parameter

Instrument type |

PCH-600D1/DG1(500°C) |

Pressure range |

0-60.0 tons |

Piston diameter |

Chrome plated cylinder Φ150mm(d) |

Overall structure of subject |

The equipment has no sealed connection to reduce oil leakage points |

Die heating temperature |

Room temperature -300.0℃ /500.0℃ |

Constant temperature time |

1 s to ∞ s |

Temperature control accuracy |

0.1 ℃ |

Heat insulation method |

Imported heat shield |

Cooling method |

Water cooling rapid cooling [Water cooler selection] |

Die size |

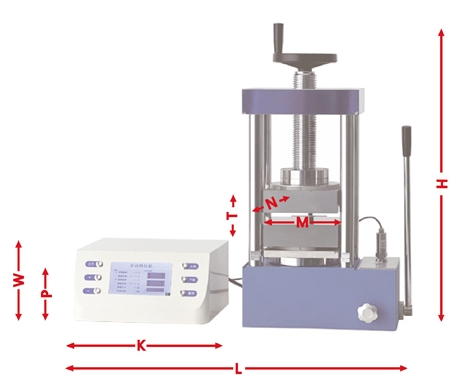

180x180mm(MXN) |

Main engine size |

405x260x525mm(KxPXH) |

Overall size |

950x260x525mm(LxWXH) |

Power source |

1000 W(220V/110V can be customized) |

Main engine weight |

180 Kg |

Powder tablet press size diagram |

|

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588