products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

5000A/8000A Pneumatic Inverter DC Spot Welding Machine for Power Battery Pack

Model Number:

TMAX-DC-01Type:

PneumaticInput Power:

35KVADimension(L*W*H):

185x280x420mmCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic PVC and Nickel Strip Cutting Machine for Alloy Strip CuttingNext:

18650/26650/32650 Cylindrical lithium Battery Labling Insulation Paper Sticking/Pasting Machine

5000A/8000A Pneumatic Inverter DC Spot Welding Machine for Power Battery Pack

Features:

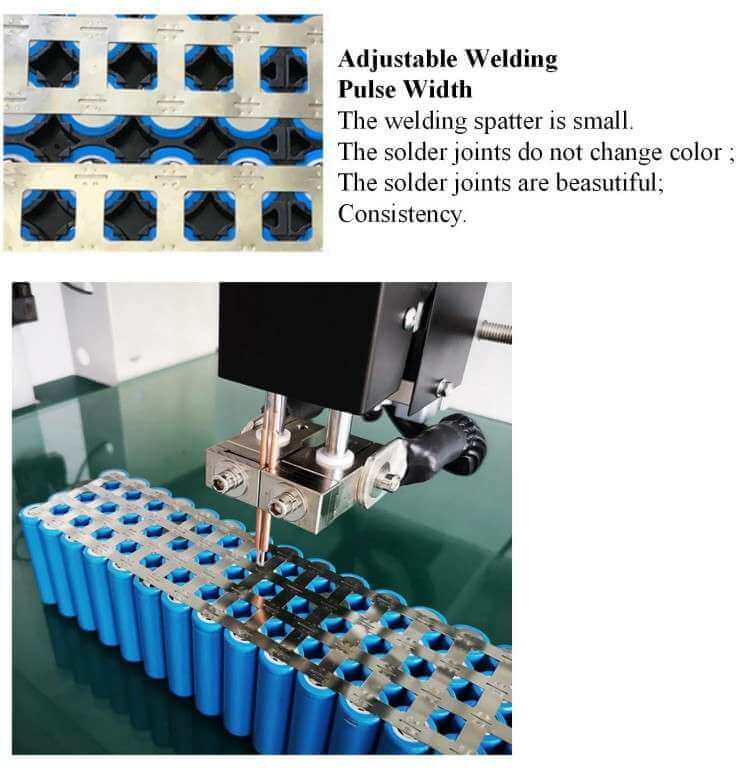

*Suitable for 18650, 26650..Battery pack welding, like E-bike, scooter and electro mobile battery pack welding.

*Induction load voltage, feedback mode to control the constant voltage, to achieve high-quality welding.

*PRE HEAT, MAIN HEAT power mode, preheats before welding, to ensure a stable welding quality.

*To maintain the continuity of energy density welding time is short, reduce the base metal deformation and discolor.

*Easy to change from low current to high current, suitable for precision welding.

*Can set the upper and lower limits of the current, simply determine the quality of welding is good or not.

*The welding current increases with the welding time to ensure the welding results.

Advantages:

1.The current is rectified in order to supply DC welding current.

2.It helps to reduce the energy of iron core material.

3.Transform the electric energy into DC power

4.DC output.Heat concentration,the heat efficiency is increased, the welding process is stable, the welding quality is improved, and the electrode life is prolonged.

Get the best prices on electrode welding machine from Tmax.

Technical parameters:

Current |

5000A |

8000A |

Input Power |

AC 380V±10%, 50Hz±2Hz |

AC 380V±10% , 50Hz±2Hz |

Rated capacity |

25KVA |

35KVA |

Maximum output short circuit current |

5000A |

8000A |

Output current range |

800-5000A |

500-8000A |

Output voltage |

10V |

10V |

Inverter frequency |

4KHz |

4KHz |

Welding time |

1.0ms—99.0ms adjustable, accuracy:0.1ms |

1.0ms—99.0ms adjustable, accuracy: 0.1ms |

Welding pulse section |

2 |

3 |

Welding cycle period |

1 |

11 |

Working table size |

600mm*800mm |

600mm*800mm |

Welding range |

580mm*580mm |

580mm*580mm |

Adjustable height range of welding head |

10-150mm |

10-150mm |

Welding needle specification |

1.5mm-3mm/6mm optional |

1.5mm-3mm/6mm optional |

Adjustable distance between welding needles |

0-10mm |

0-10mm |

Adjustable stroke of cylinder |

5-30mm |

5-30mm |

Specification of secondary discharge cable |

95mm² |

95mm² |

Cable length |

500mm |

500mm |

Adjustable range of welding head pressure |

1-5kg |

1-5kg |

Welding speed |

0.5-0.8s/point |

0.5-0.8s/point |

Plane double needle welding thickness |

0.08-0.25mm plated nickel/pure nickel |

0.08-0.3mm plated nickel/pure nickel |

Welding thickness of convex point and flat needle |

0.15-0.3mm plated nickel/pure nickel |

0.2-0.5mm plated nickel/pure nickel |

Number of settable specifications |

8 |

99 |

Display |

LED |

TFT 800X480 Capacitive touch screen |

Over limit alarm setting mode |

Current setting |

Current setting + current wave monitoring |

Welding mode |

Single welding |

Single or double welding |

control mode |

PWM |

PWM |

Control way |

1200V 200A IGBT |

1200V 300A IGBT |

Control mode |

Constant current |

Constant current and constant voltage |

Cooling |

Forced air cooling |

Forced air cooling |

Weight |

35KG |

40KG |

Weight of main machine |

430L*185W*280H mm |

455L*205W*315H mm |

Transformer size |

265L*180W*255H mm |

475L*200W*290H mm |

Whole main size |

800Lx600Wx1200H mm |

800Lx600Wx1200H mm |

Welding application |

Battery connection piece, hardware sheet, wire harness, terminal block, etc |

Battery connection piece, hardware sheet, wire harness, terminal block, etc |

Product Details:

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588