products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

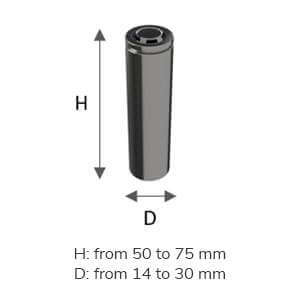

100MWH/1GWH LFP NMC LTO Cylindrical Cell Production Line

Model Number:

TMAX-ACPLType:

Semi-automatic /AutomaticCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPlace of Origin:

ChinaShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western Union

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

High Precision Continuous Hydraulic Hot Calender Roller Press MachineNext:

Auto Cylindrical Cell PVC Film Laser Cutting and Removal Machine

100MWH/1GWH LFP NMC LTO Cylindrical Cell Production Line

I. Introduction

Cylinders are mainly steel cylinder lithium iron phosphate battery, which has high capacity, high output voltage, good charging and discharging cycle performance, stable output voltage, high current discharge, electrochemical stability, safety in use (no combustion or explosion due to improper operation such as overcharging, over discharge and short circuit), wide operating temperature range, and environmental friendliness. Widely used in solar lighting fixtures, lawn lighting fixtures, backup energy, electric tools, and toy models.

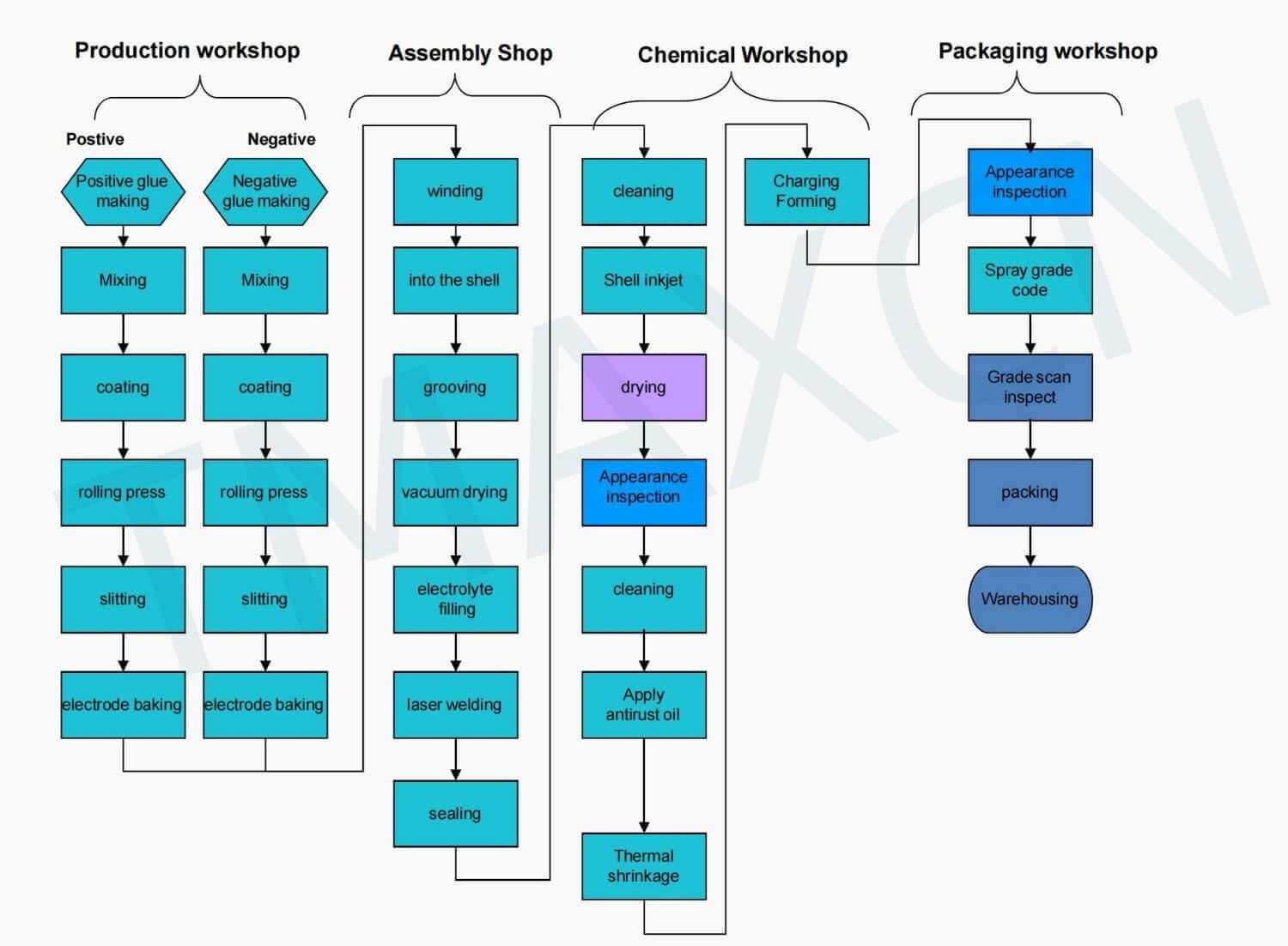

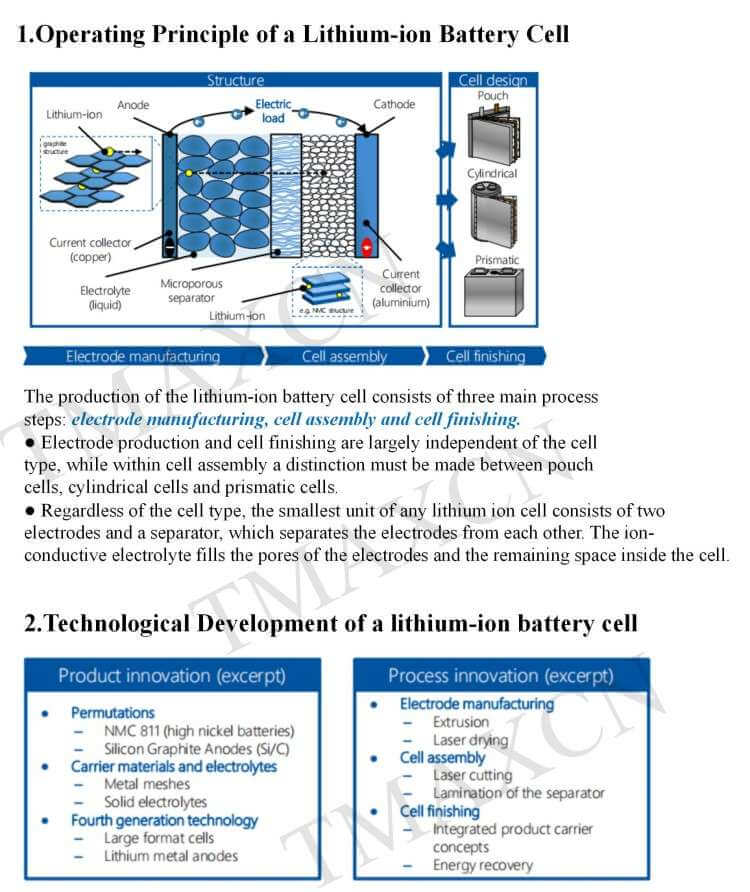

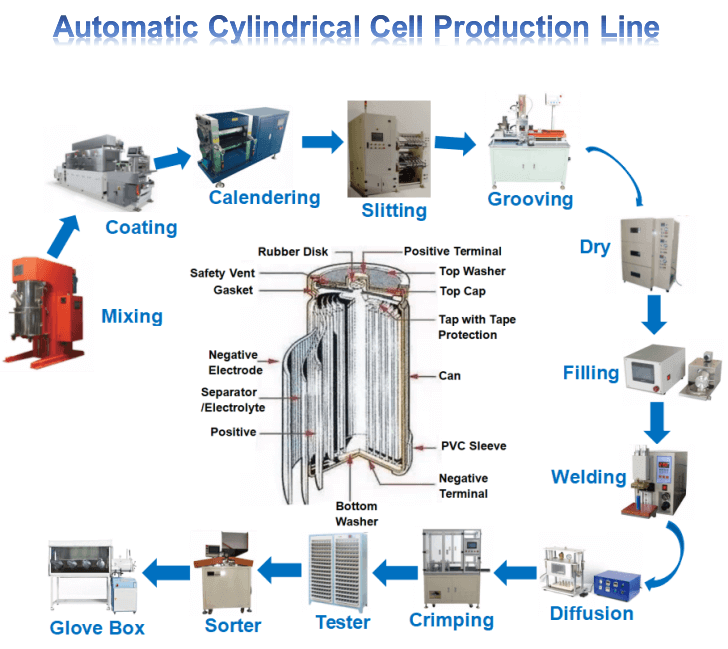

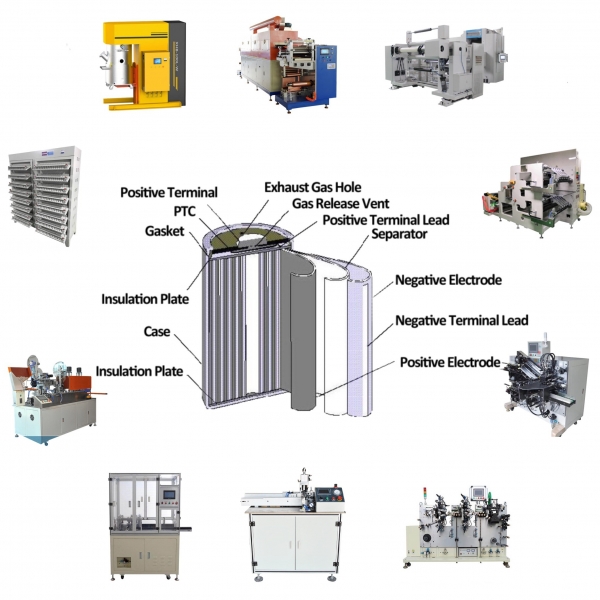

Ⅱ、LITHIUM-ION BATTERY CELL PRODUCTION PROCESS

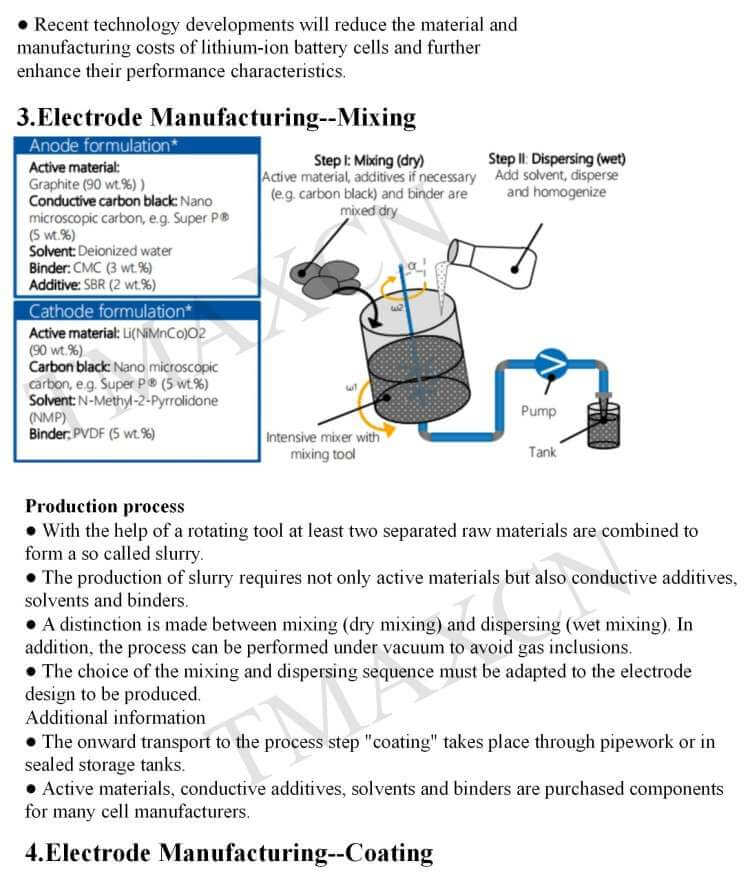

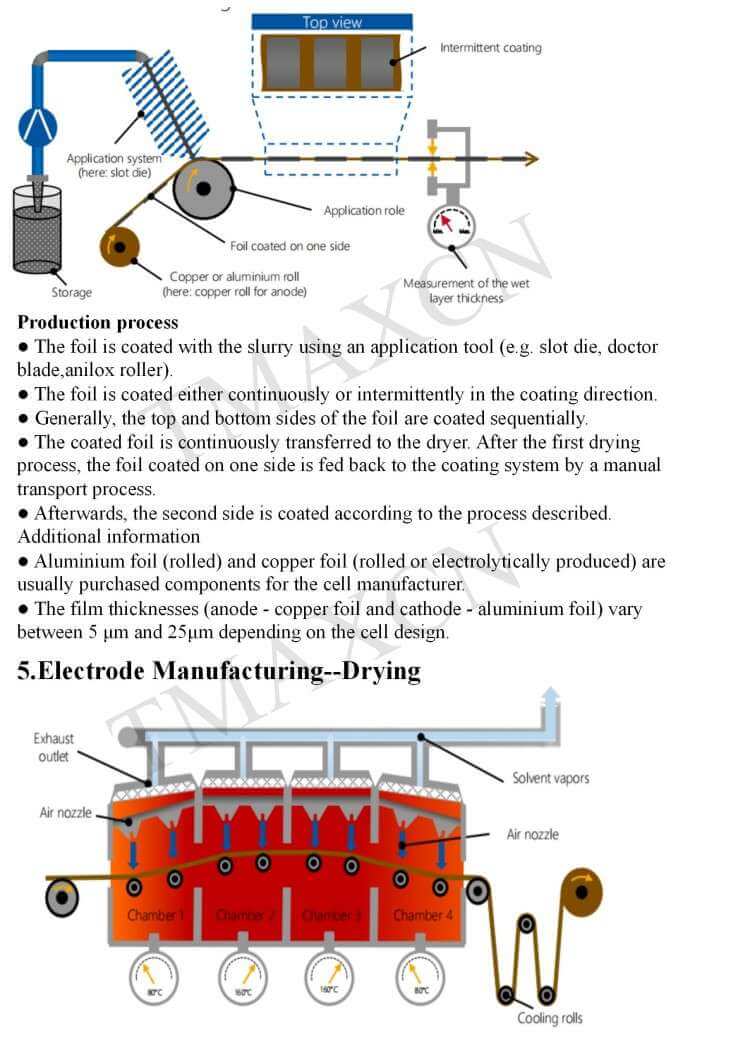

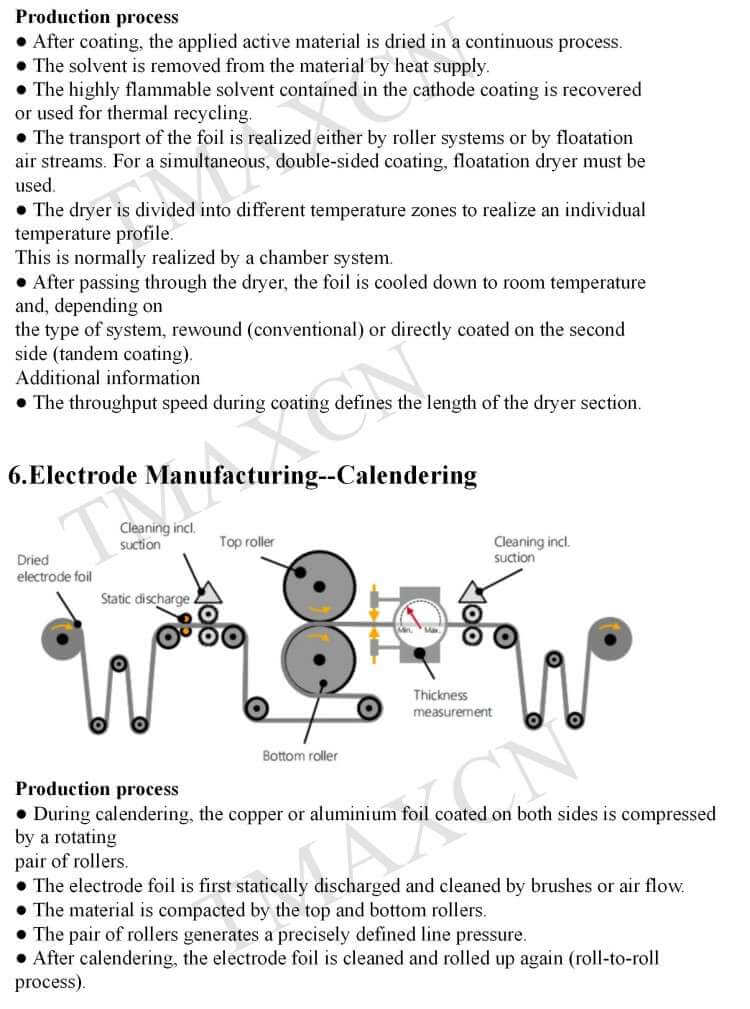

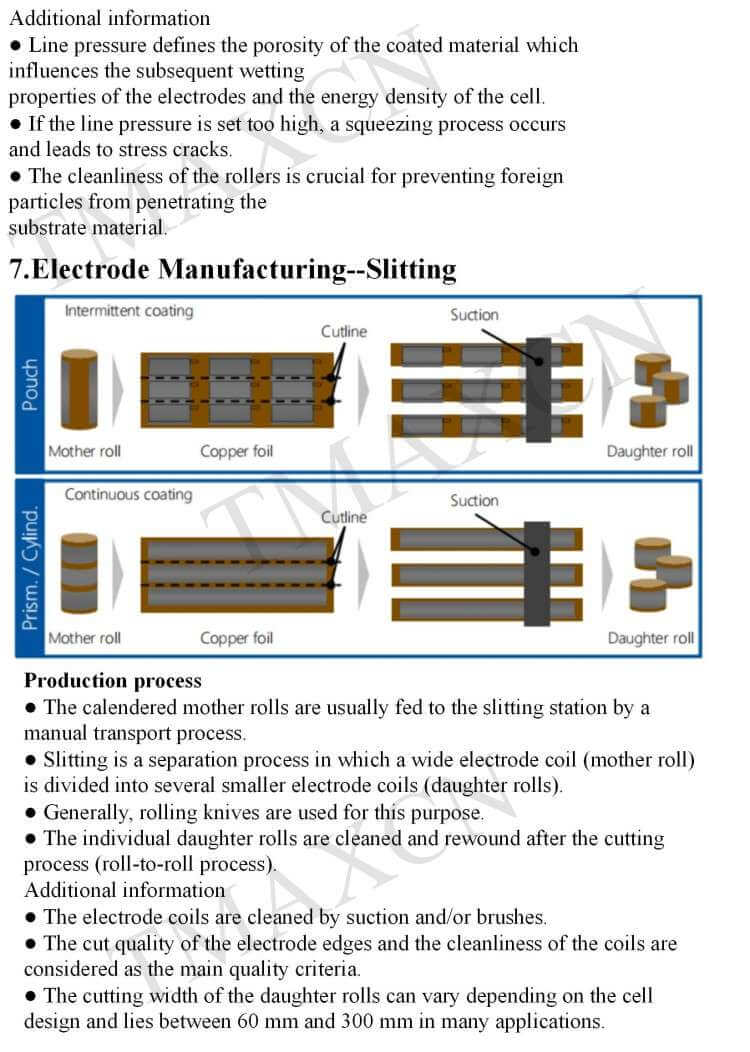

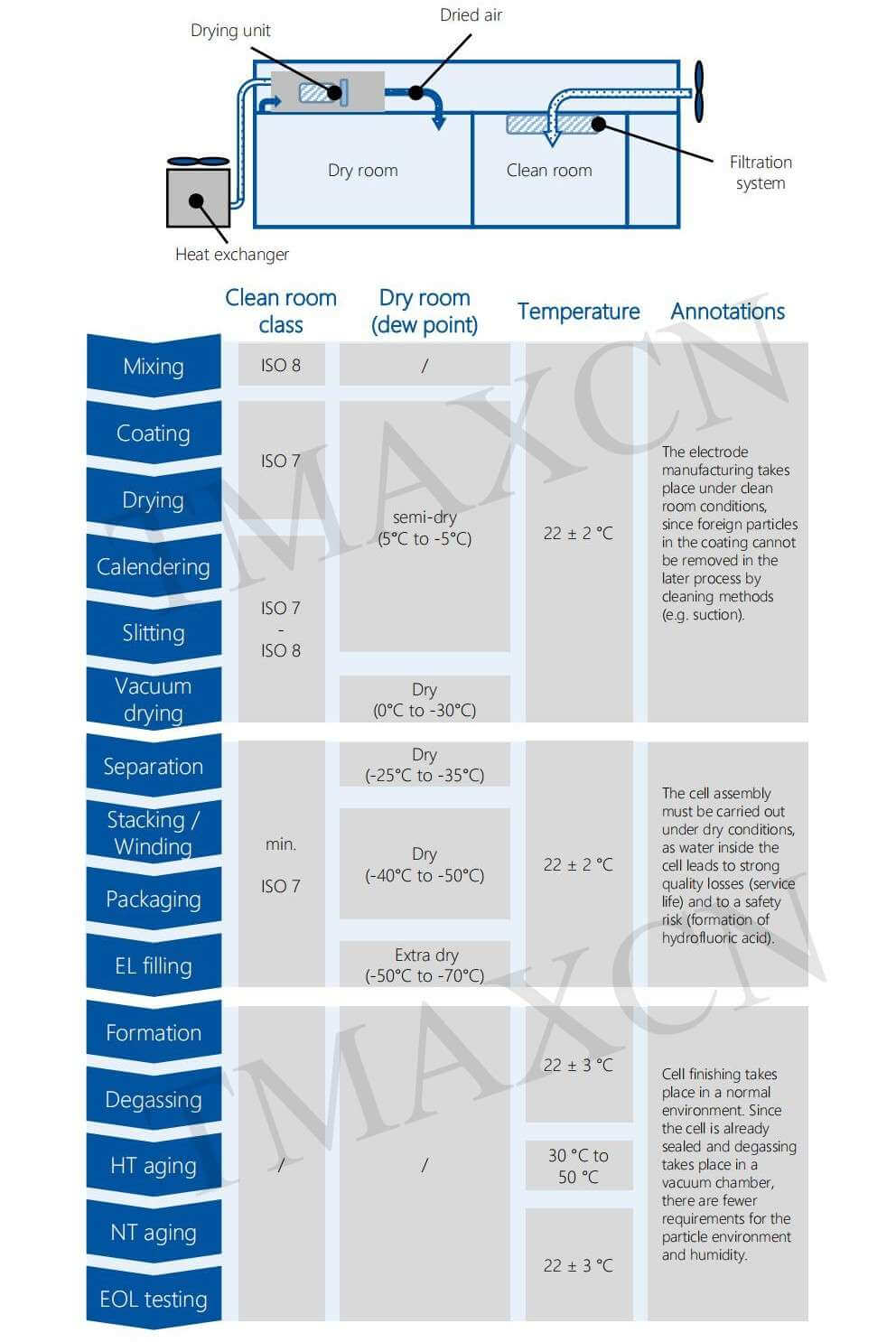

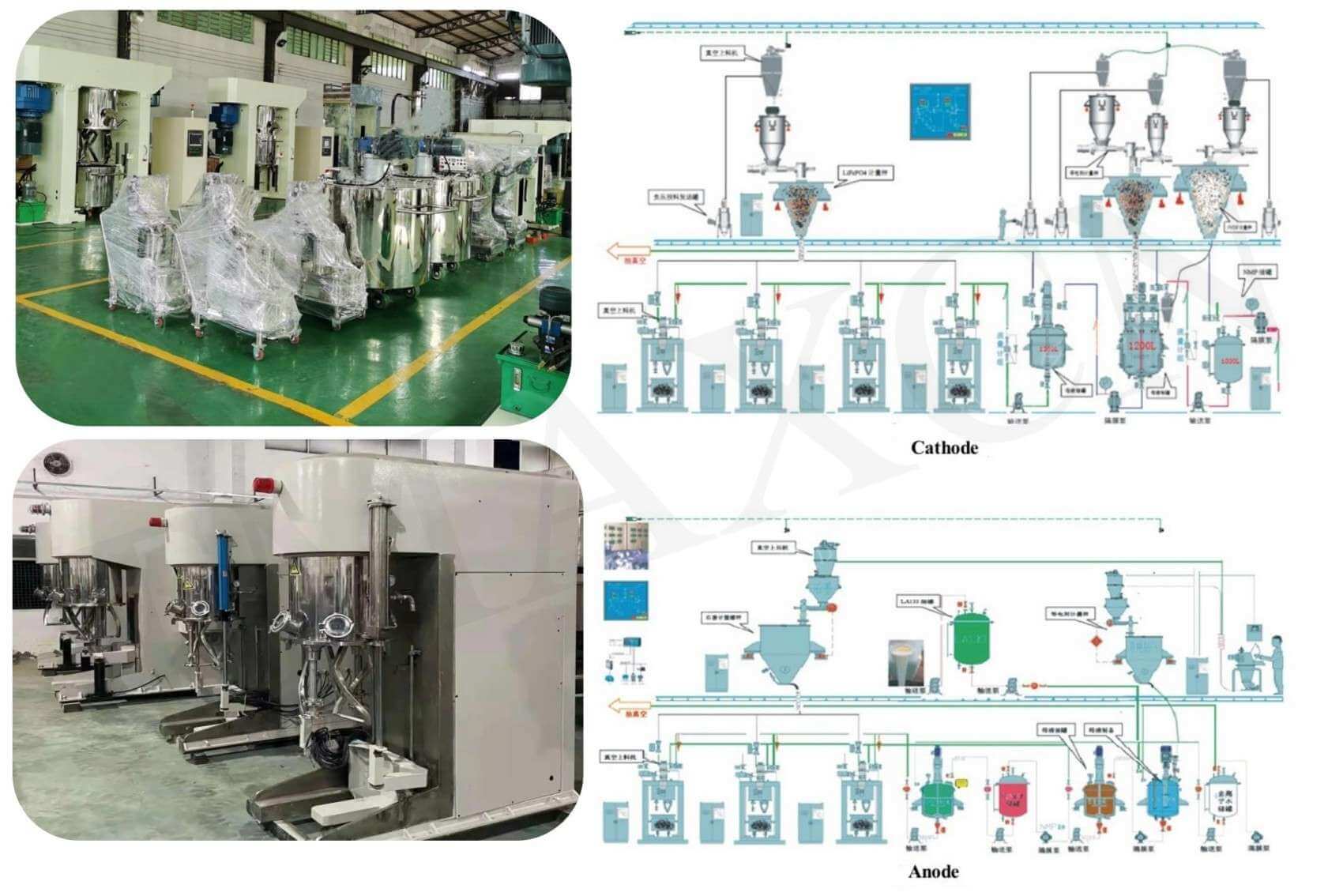

Ⅲ、Detail Description about Electrode Manufacturing

8. Dry Room

Ⅳ. Plant Display

Ⅴ. Procurement process

TMAX follows a comprehensive procurement process to ensure a seamless experience for our customers.

1) Initial Consultation: We have an in-depth discussion with the customer to understand their battery production requirements, machine specifications, and budget constraints.

2) Proposal Preparation: Based on the consultation, we create a detailed proposal that outlines our recommended battery-making machines, pricing, delivery timelines, and additional services or support.

3) Proposal Presentation: We present the proposal, highlighting the features and benefits of our machines, addressing customer questions, and explaining how our solution meets their needs.

4) Negotiation and Agreement: We engage in negotiations to address concerns and modify the proposal if needed, aiming to reach a mutual agreement on pricing, terms, and conditions.

5) Purchase Order: The customer issues a purchase order (PO) that formalizes the agreement, specifying quantities, prices, delivery dates, and contractual obligations.

6) Order Fulfillment: We manufacture or source the battery-making machines according to agreed specifications, conducting quality control checks to ensure high performance and reliability.

7) Shipment and Delivery: We handle packaging, transportation, and customs clearance, providing tracking information and updates on the shipment's status.

8) Installation and Training: Our technicians offer installation services and comprehensive training on machine operation, maintenance, and troubleshooting.

9) Post-Sales Support: We provide ongoing customer support, including assistance with spare parts, maintenance, upgrades, and expansions, to ensure customer satisfaction.

By following this streamlined procurement process, we deliver high-quality battery-making machines tailored to our customers' requirements while providing excellent support throughout their lifecycle.

Ⅵ. Manufacturing Cycle and Planning

No. |

Project |

1st month |

2nd month |

3rd month |

4th month |

5th month |

6th month |

||||||

1 |

◎ Confirmation of idea/plan/specification |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

◎ Customized design for key parts |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

◎ Mechanical part design |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

◎ Control part design |

|

|

|

|

|

|

|

|

|

|

|

|

5 |

◎ Procurement of processed parts/outsourced parts |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

◎ Mechanical assembly |

|

|

|

|

|

|

|

|

|

|

|

|

7 |

◎ Electrical debugging |

|

|

|

|

|

|

|

|

|

|

|

|

8 |

◎ Single test |

|

|

|

|

|

|

|

|

|

|

|

|

9 |

◎ Linkage trial operation and on-site customer placement |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

◎ Trial run/final acceptance |

|

|

|

|

|

|

|

|

|

|

|

|

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588