products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

-

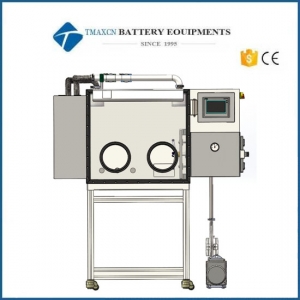

Vacuum Glove Box Single Side Single Work Station with Purification System

Vacuum Glove Box Single Side Single Work Station with Purification System

Vacuum Glove Box Single Side Single Work Station with Purification System Acceptance Criteria Under standard conditions, namely 20-25℃constant temperature, relative humidity 65%, 99.999% inert air source, empty tank circulating water oxygen index is less than 1ppm. Main technical indicators and configuration 1. The box body 1.1. Dimensions: 1200mm (L) x 900mm (H) x 770mm (W). 1.2. Material: stainless steel structure (Type 304), thickness 3mm. 1.3. Filter: aperture 0.3 micron 1.4. Butyl rubber gloves: the thickness of the original import from the United States 0.4mm, 2 ah glove mouth 8 inches, duraluminum-alloy glove mouth (after corrosion treatment, anodized aluminum oxide), 220mm diameter. 1.5. Windows: sloped design operating surface, removable 8mm safety toughened glass front window, wear, corrosion resistance, good light transmission, and a 3/8 inch thick OMEGA seal ring. 1.6. Can maintain a certain positive and negative pressure (-10mbar-10mbar) 1.7. Box is equipped with anti - reflection lighting energy-saving lamp, soft light. 1.8. The box body is provided with display board 2 shelves 1.9. The box body is provided with a porous power supply junction board (Thai plug 220V, 50 Hz) 1.10. Four standard KF-40 ports can be installed in the box. 1.11. Leakage rate: ≤0.001vol%/h. 1.12. Steel structure bracket, 950 mm high with casters, equipped with universal casters. 2. Transition module 2.1. Shape: Cylindrical (304 stainless steel), connected to glove box, with shaft lock large transition door for easy operation. 2.2. Size: 390mm in diameter, 600mm in length large transition chamber, piston door, sliding tray in transition chamber, polishing, a small transition chamber is set in the box, specification: 150mm in diameter, 300mm in length, manual valve control of air pumping and filling. 2.3. Pallet: Free to move and extend (large transition cabin configuration) 2.4. Vacuum ≤1bar(both large and small right transition compartments require vacuum belt display) 3. Control system 3.1. Mode: including self - diagnosis, power - off self - start characteristics, with pressure control and self - adaptation functions. Automatic control, cycle control, password protection, vacuum chamber control using LCD display. Unit control adopts Siemens PLC touch screen. 3.2. Pressure control: control the pressure of the chamber and the transition chamber at a certain set point. A) The user can arbitrarily set the working pressure interval between +12.5 and -12.5 mbar, and PLC will automatically regulate the pressure of the box within the set range. The default operating pressure range is -1 to +3 mbar. B) When the box pressure is greater than 12 mbar, PLC automatically opens the safety valve to relieve pressure and protect gloves, equipment and materials in the box. C) Use foot switch to fine tune the box pressure. 3.3. Foot pedal: can control the pressure of glove box, easy to operate. 4. Circulation system (including purification and regeneration system) 4.1. Germany BASF, United States UOP purification materials, Germany Baode valve. The host system is integrated with modular design. The automatic electronic control gas path solenoid valve set, PLC control, circuit, circulating pump, purification house and display are integrated with an independent purifier, forming a compact and simple system. 4.2. Control: water and oxygen are controlled in less than 1PPm 4.3 Adjustment device: through PLC touch type adjustment (heating, evacuation, purification, regeneration) the whole process except 2.5 hours ventilation without human monitoring. 4.4. Working gas: HE. N2/ or Ar gas (gas circulation) 4.5. Circulating fan: 0-100M ³ high speed variable frequency fan, microprocessor control, pressure tested stainless steel device. 4.6. Purification column: single purification column, imported purification material Germany BASF deoxygenation material 5kg, the United States UOP high-efficiency water absorption material 5kg, extremely high life degree, to ensure that users in the process of using the product's purification ability long lasting. Water removal capacity 2.2㎏ oxygen absorption capacity 63L. 4.7. Purification valve: automatic electro-pneumatic valve. 4.8. Filter: High efficiency filter with 0.3 micron aperture mesh conforming to HEPA standard. 4.9 Regeneration: used for reuse of purification system to activate it; Regeneration requires a mixture of helium /H2, nitrogen /H2 or argon /H2, with H2 accounting for 10%. And then the advanced flow meter into the purification column. 5. Display system SIEMENS, unit control adopts SIEMENS PLC touch screen. You can switch between Chinese and English. Water analyzer, (imported from abroad) brand material: British MICHELL/ (according to the customer's use of the environment decision) Non-domestic or domestic assembly, third party data to ensure credibility. 1) Measurement range: 0-1000ppm 2) Accuracy: ±1% PPM 3) Display: The output of the analyzer is connected to PLC, the detection value is displayed on the touch screen, and the alarm value can be set. 4) Control: The gas circulation system can be controlled according to the user's setting to achieve circulation reduction. 5) Environment: -10℃ -- 50℃ 6. Oxygen analyzer, (imported from abroad) Brand material: AVCRAY (electrochemical material battery) Non-domestic or domestic assembly, third party data to ensure credibility. 1) The measurement range can be set: 0-1000ppm 2) Environment: -10℃ -- 50℃ 3) Accuracy: ±1% PPM 4) Installation position: The oxygen sensor is installed on the box, no matter whether the gas is circulating or not, the oxygen sensor can continuously detect the atmosphere in the box and display the oxygen content in the glove box. 5) Sensor: electrochemical material battery, its advantages are accurate zero point, small drift, avoid other battery materials easy to be corroded; Low replacement cost (only oxygen batteries). 6) Display: The output of the analyzer is connected to PLC, the detection value is displayed on the touch screen, and the alarm value can be set. 7) Control: Users can choose the automatic cycle function to maintain the oxygen content in the glove box within the user's prescribed range. 7. Vacuum system Increase the vacuum pump start and stop time control. Vacuum pump adopts British Edwards vacuum pump, model RV12, flow rate 12m3/h, limit vacuum 2x10-3 millibar. The transition chamber can be vacuumed separately and controlled individually at any time. (Imported from abroad) 8. Automatic cleaning of box Automatic air-controlled electroplating plate; The user sets the cleaning time, and then touches the start button on the touch screen, the system will start cleaning the box, and will stop automatically at the set time. 9. Organic solvent adsorption system In order to prevent the influence of organic solvents on the purification column, a solvent column was connected in series to the glove-box system. The medium was mainly high quality and efficient activated carbon and activated alumina to prevent the formation of hydrofluoric acid. The filling capacity of the organic solvent adsorption system is 7KG. There are KF40 interfaces on the upper and lower parts of the column, which is convenient for refueling. Users can refueling by themselves. 10. Equipment working conditions :(provided by the user) 1.0. Power supply: two-phase three-wire AC220V, power ≥ 1.5KW; 1.1. The laboratory should have an independent ground wire: < 3ω, from the equipment to the ground wire connection is recommended to use more than 10mm2 flat copper wire; 1.2. Water supply: none; 1.3. Relative humidity: < 75%; 1.4. There is no large amount of dust, corrosive, flammable and explosive gas in the room; 1.5. Equipment floor area: length × width :2000mm× 1200mm The main configuration No Configuration Unit Qty Manufacturer/Brand Note 1 Box Unit 1 TMAXCN 304 stainless steel Thickness 3mm 2 Transition cabin Set 1 TMAXCN 304 stainless steel 3 Control system Set 1 Germany SIEMENS Omron electronic devices, etc Imported assembly 4 Circulation system (including purification and regeneration system) Set 1 Germany BASF, the United States UOP purification materials, Germany Baode valve Imported assembly 5 Display system Set 1 Germany SIEMENS Import 6 Gloves Pair 1 The United States Import 7 Pipeline interface Set 1 French Lecolor Import 8 Pressure gauge Set 1 Germany WIka Import 9 PLC water analyzer Unit 1 The British michelle Import 10 PLC oxygen analyzer Unit 1 The United States AVCRAY Import 11 Vacuum pump Unit 1 RV12 Import 12 Organic solvent adsorption Set 1 TMAXCN Activated carbon + activated alumina

-

Multi Station Purification Single Side Glove Box with Vacuum System

Multi Station Purification Single Side Glove Box with Vacuum System

Multi Station Purification Single Side Glove Box with Vacuum System A. Acceptance criteria: Under standard conditions, that is 20-25 ℃ constant temperature, 65% relative humidity, and 99.999% inert gas source, the circulating water and oxygen indicators of the empty tank are all less than 1ppm. B. Main technical indicators and configuration 1. Cabinet 1.1. Dimensions: 1500mm (length) x 900mm (height) x 750mm (width). 1.2. Material: All stainless steel structure (Type 304), thickness 3mm. 1.3. Filter: pore size 0.3 microns 1.4. Butyl rubber gloves: imported from the United States with a thickness of 0.4mm, a glove opening of 8 inches, a hard aluminum alloy glove opening (after anti-corrosion treatment, anodized aluminum), and a diameter of 220mm. 1.5. Window: Inclined design of the operating surface, 8mm safety tempered glass front window, wear-resistant, corrosion-resistant, good light transmission, and the sealing ring adopts a 3/8 inch thick OMEGA sealing ring. 1.6. It can maintain a certain positive and negative pressure (-10mbar-10mbar) during use 1.7. The cabinet is equipped with anti-reflection lighting energy-saving lamps, and the light is soft. 1.8. There are 2 layers of shelves for display boards in the box 1.9.There is a porous power terminal board in the box (power supply: 220V±10% 50Hz±10%) 1.10. The cabinet can be equipped with 4 standard KF-40 interfaces. 1.11. Leakage rate: ≤0.001vol%/h. 1.12. The steel structure bracket, including casters, is 950 mm high, and is equipped with universal casters. 2. Transition cabin 2.1 Large and small transition chambers (right side) 2.1.1 Shape: Cylindrical (304 stainless steel), connected to the glove box, with a shaft lock type large transition hatch, easy to operate. 2.1.2 Diameter 360mm, length 600mm large transition chamber, piston door, there is a sliding tray in the transition chamber, polished, the box is equipped with a small transition chamber, the specifications are: diameter 150mm, length 300mm, manual valve control air extraction and supply. 2.1.3. Tray: free to move and extend (large over-chamber configuration) 2.1.4. Vacuum degree ≤ 1bar (both large and small right transition cabins require vacuuming with display) 3. Control system 3.1. Method: Including self-diagnosis, self-starting after power failure, with pressure control and self-adaptive functions. LCD display is used for automatic control, cycle control, password protection and vacuum chamber control. The unit control adopts Siemens PLC touch screen. 3.2. Pressure control: control the pressure of the tank and transition chamber at a certain set value. a ) The user can arbitrarily set the working pressure range between +12.5 and -12.5 mbar, and the PLC will automatically control the pressure of the box within the set range. The default value for the working pressure range is -1 to +3 mbar. b) When the box pressure is greater than 12 mbar, the PLC will automatically open the safety valve to release the pressure to protect the gloves, equipment and materials in the box. c) Use the foot switch to fine-tune the tank pressure. 3.3. Foot pedal: It can control the pressure of the glove box and facilitate operation. 4. Circulation system (including purification regeneration system) 4.1. German BASF, American UOP purification materials, German Baode valves. The host system integrates a modular design, fully automatic electronically controlled air circuit solenoid valve group, PLC control, circuit, circulation pump, purification chamber, and display are integrated into an independent purifier, forming a compact and simple system. 4.2. Control: water and oxygen are controlled at less than 1PPm 4.3. Adjustment device: through PLC touch adjustment (heating, evacuation, purification, regeneration) the whole process except 2.5 hours of ventilation without human monitoring. 4.4. Working gas: He.N2/ or Ar gas (gas cycle) 4.5. Circulation fan: 0-100m³ high-speed variable-frequency fan, microprocessor-controlled, pressure-tested stainless steel device. 4.6. Purification column: single purification column, imported purification material BASF oxygen removal material 5kg from Germany, UOP high-efficiency water-absorbing material from the United States 5kg, extremely high lifespan, ensuring long-lasting purification ability of the product during use by users. The water removal capacity is 2.2㎏ and the oxygen absorption capacity is 63L. 4.7. Purification valve: fully automatic electro-pneumatic valve. 4.8. Filter: A high-efficiency filter with a 0.3-micron pore size filter that meets HEPA standards. 4.9. Regeneration: It is used to re-use the purification system to activate it; regeneration requires a mixed gas of helium/H2, nitrogen/H2 or argon/H2, of which H2 accounts for 10%. The regeneration gas enters the purification column through the advanced flow meter. 5. Display system Germany SIEMENS, unit control adopts Siemens PLC touch screen. Chinese and English bilingual can be switched. 6. Water analyzer(imported from abroad) Brand material: British MICHELL/ (determined according to the customer's use environment) Non-domestic or domestic assembly, third-party data guarantee credibility. 1) Measuring range: 0-1000ppm 2) Accuracy: ±1%ppm 3) Display: The output of the analyzer is connected to the PLC, the detected value is displayed on the touch screen, and the alarm value can be set. 4) Control: The gas circulation system can be controlled according to the user's settings to achieve circulation reduction. 5) Environment: -10℃—50℃ 7. Oxygen analyzer(imported from abroad) Brand material: American AVCRAY (determined according to the customer's use environment) Non-domestic or domestic assembly, third-party data guarantee credibility. 1) Measuring range can be set: 0-1000, ppm 2) Environment: -10°C - 50°C 3) Accuracy: ±1% ppm 4) Installation position: The oxygen sensor is installed on the box body. No matter whether the gas circulates or not, the oxygen sensor continuously detects the atmosphere in the box and displays the oxygen content in the glove box. 5) Sensor: Electrochemical material battery, which has the advantages of accurate zero point, small drift, and avoids easy corrosion of other battery materials; low replacement cost (only oxygen battery is replaced). 6) Display: The output of the analyzer is connected to the PLC, the detected value is displayed on the touch screen, and the alarm value can be set. 7) Control: The user can choose the automatic circulation function to maintain the oxygen content in the glove box within the specified range of the user. 8. Vacuum system Increase the start and stop time control of the vacuum pump. The vacuum pump is an Edwards vacuum pump from England, model RV12, with a flow rate of 12m3/h and an ultimate vacuum of 2x10-3 mbar. The transition chamber can be evacuated separately and can be controlled independently at any time. (Imported from abroad) 9. Automatic cleaning of the cabinet Automatic air control electroplating plate; automatic gas cleaning function in the box The user sets the cleaning time, and then touches the start button on the touch screen, the system will start cleaning the box, and it will automatically stop when the set time is reached. 10. Organic solvent adsorption system In order to prevent the influence of organic solvents on the purification column, a solvent column is connected in series to the glove box system. The medium is mainly high-quality and efficient activated carbon and activated alumina to prevent the formation of hydrofluoric acid. The filling capacity of the organic solvent adsorption system is 7KG, and there are KF40 interfaces on the upper and lower sides of the column, which is convenient for refueling, and the user can refuel by himself. 11. Equipment working conditions: (provided by the user) 1.0. Power supply: two-phase three-wire AC220V, power ≥ 1Kw; 1.1. The laboratory must have an independent ground wire: <3Ω, it is recommended to use a flat copper wire of ≥10mm2 for the connection from the equipment to the ground wire; 1.2. Water supply: no; 1.3. Relative humidity: <75%; 1.4. There is no large amount of dust in the room, no corrosive, flammable and explosive gases; 1.5. Equipment covers an area: length × width: 2500mm × 1200mm C. Main configuration Serial number Configuration Unit Number Manufacturer /Brand Remark 1 Cabinet Set 1 TMAX 304 stainless steel thickness 3mm 2 Transition cabin Set 1 TMAX 304 stainless steel 3 Control System Set 1 German SIEMENS Omron electronic devices, etc. Import assembly 4 Circulation system (including purification regeneration system) Set 1 German BASF, American UOP purification materials, German Baode valves Import assembly 5 Display system Set 1 Germany SIEMENS Import 6 Gloves Pair 3 U.S. Import 7 Pipe interface Set 1 Legola Import 8 Pressure gauge Set 1 WIka, Germany Import 9 PLC water analyzer Set 1 Michell, United Kingdom Import 10 PLC oxygen analyzer Set 1 American AVCRAY Import 11 vacuum pump Set 1 RV12 Import 12 Organic solvent adsorption Set 1 TMAX 304 stainless steel

-

Single Side Stainless Steel Glove Box Vacuum Glovebox with Purification System and Dedusting System

Single Side Stainless Steel Glove Box Vacuum Glovebox with Purification System and Dedusting System

Single Side Stainless Steel Glove Box Vacuum Glovebox with Purification System and Dedusting System I. Main models SVGB Series Stainless Steel Vacuum Glove Box Parameter List SVGB series vacuum glove box SVGB-1 SVGB-2 SVGB-3 Shape (L*W*H) 1030*580*540 1320*750*690 1755*800*1024 Box (length L width W height H thickness T) 600*500*500*5 800*650*650*5 1200*700*950*6 Net space inside the box (upper) 460*340*490 660*460*640 1060*563*938 Net space inside the box (lower) 460*490*490 660*640*640 1060*688*938 Window glass (L*H*T) 548*243*19 748*373*19 1148*435*19 Bracket (L*W*H1) 600*500*883 800*650*858 1200*700*808 Transition cabin φ200*280 φ273*350 φ350*400 Left side door opening (optional) 330*260 360*480 450*600 Transition compartment drawer (optional) 126*250 202*320 282*350 Tool compartment (optional) / / 150*300 Glove hole diameter φ150 φ150 φ196 Glove material and size Rubber φ160*700 Rubber φ160*700 Rubber φ180*750 Center distance between two glove holes 300 400 450 Glove hole height from the bottom of the box 125 150 200 Box working pressure range -0.1—0 MPa -0.1—0 MPa -0.1–0 MPa Leakage rate -0.1MPa Holding pressure for 12 hours, temperature constant pressure increase <0.003MPa=3KPa (Level 2 per 1SO10648) Optional Fully automatic humidity system Fully automatic control of the humidity/moisture inside the chamber, out of the humidity blindness. Fully automatic pressure system Constant pressure inside the chamber, especially for hazardous powder leakage. Ovens If vacuum baking is required, you can select the over-bin heating mode Purification system After vacuuming the inert gas, the water oxygen value is usually around 200PPM. Purification system, can achieve water oxygen value <1PPM Dedusting system Internal purification level, class 100/class 1,000, with optional dust removal system II. Product introduction Vacuum glove box, also known as vacuum inert gas glove box, in the process of scientific experiments, some substances in the atmospheric state is very easy to oxidize and deliquescence, which makes the chemical reaction of the test substance and the sample of the front-end processing is very difficult, affecting the test process and test results. Vacuum glove box (also known as vacuum inert gas operation box) effectively solves these problems, the device can make the test samples can be safely put in and take out, and in the state of oxygen and water free operation, reaction and testing, to ensure the normal conduct of scientific experiments. This product is an ideal device for scientific experiments in colleges and universities, scientific research units and enterprise laboratories, and is widely used in biochemical, metallurgical, electronic, chemical, geological, mineral, pharmaceutical and other industries. Stainless steel vacuum glove box is a high-purity inert gas filled into the box, and the cycle of filtering out the active substances in the laboratory equipment, also known as the glove box, inert gas protection box, dry box and so on. III. Product structure principle Stainless steel vacuum glove box is mainly composed of the main box, transition chamber and frame, such as users have other special requirements, can also be designed or modified according to the needs; box on the two to three glove operation interface, the operating box to meet the face of the toughened glass, a wide perspective without dead ends, the operator can clearly observe the operation process in the box, so that the process of the operation of the more intuitively displayed in front of the operator's eyes. Box, the transition chamber has two vacuum ball valves for gas in and out of the box, box on the reserved KF40 vacuum connector, the user can be used according to need, in the need for water or gas can be accessed from this situation. The box has built-in lighting and multi-hole socket. IV. Product features 1. The whole box is made of stainless steel, and made of reinforced treatment, the surface plastic spraying, so solid corrosion-resistant and easy to clean; 2. The operation box is made of plexiglass, with wide view angle and no dead angle; 3. Inside the box with lighting and sockets; 4. The operating gloves are made of imported butyl gloves, which are reliable and durable; 5. The sealing device is novel in design, reliable sealing and easy to open; 6. The box is reserved for KF40 vacuum connector, which can be transformed and used according to the needs; 7. The two doors of the transition room solve the problem of repeated vacuuming of the main box. V. Product use precautions 1. Before use, you must check whether the connections are loose and whether the seals are intact; 2. It is forbidden to open the hatch, glove port cover or disassemble and repair under vacuum; 3. The glove port should be vacuumed firstly or simultaneously with the box, and then stop vacuuming with the box at the same time or at the same time; 4. The connection of external gas source pipe fittings should be sealed securely, and the inlet valve should be closed when the needle of vacuum pressure gauge points to 0 when the box is inlet; 5. Close the valve and then close the vacuum pump after vacuuming; 6. Check whether the glove valve is open when pumping.

-

Six Port Purification Glove Box with T Transition Cabin

Six Port Purification Glove Box with T Transition Cabin

Six Port Purification Glove Box with T Transition Cabin A. Acceptance criteria: Under the standard condition, that is, under the constant temperature of 20-25 ℃, the relative humidity of 65%, and the inert air source of 99.999%, the circulating water oxygen index of the empty tank body reaches less than 1ppm. B. The main technical indicators and configuration 1. Box 1.1. Size: 1530mm (L) ×900mm (H) ×750mm (W) +1500mm (L) ×900mm (H) ×750mm (W). 1.2. Material: stainless steel structure (Type 304), thickness 3mm. 1.3. Filter: Aperture 0.3 micron 1.4. Butyl rubber gloves: original imported from the United States thickness 0.4mm, glove mouth 8 inches, duraluminum-alloy glove mouth (anti-corrosion treatment, anodized aluminum), diameter 220mm. 1.5. Window: Inclined design operating surface, 8mm safety tempered glass front window, wear resistance, corrosion resistance, good light transmission, sealing ring with 3/8 inch thick OMEGA sealing ring. 1.6. Maintain a certain positive and negative pressure (-10mbar-10mbar) during use 1.7. The cabinet is equipped with anti-reflection lighting energy-saving lamps, and the light is soft. 1.8. The box body is provided with a display board 2-layer shelf 1.9. The box is equipped with a porous power terminal board (Power supply: 220V±10% 50Hz±10%) 1.10. Each box is equipped with four standard KF-40 ports. 1.11. Leakage rate: ≤0.001vol%/h. 1.12. Steel structure bracket, including casters 950 mm high, installed with universal casters. 2. Transition cabin 2.1 T type large transition bin 2.1.1. Shape: T-shaped (304 stainless steel), linked glove box two boxes, three door design, easy to operate. 2.1.2. Dimensions: Diameter 390mm, length 700mm large transition cabin, piston door, transition cabin with sliding tray, polishing. 2.1.3. Pallet: Freely movable extension (The large transition compartment is equipped with). 2.1.4. Vacuum degree ≤1bar(Both large and small right transition compartments are required to be able to vacuum and display vacuum values). 2.2 Small transition warehouse 2.2.1. The two boxes are respectively provided with a small transition compartment, which is located in front of the T-bin. 2.2.2. Specifications: Diameter 159mm, length 300mm, manual valve control pumping and replenishing. 2.2.3. Vacuum degree ≤1bar(the vacuum gauge is required to display the vacuum in the transition chamber). 3. Control system (two sets) 3.1. Mode: Including self-diagnosis, power off self-start features, with pressure control and adaptive functions. Automatic control, cycle control, password protection, vacuum chamber control using LCD display. The unit is controlled by Siemens PLC touch screen. 3.2. Pressure control: Control the pressure of the box and the transition chamber at a certain set value. a) The user can arbitrarily set the working pressure range between +12.5 and -12.5 mbar, and the PLC will automatically adjust the pressure of the box within the set range. The default value of the operating pressure range is -1 to +3 mbar. b) When the box pressure is greater than 12 mbar, the PLC automatically opens the safety valve to relieve the pressure and protect the gloves, equipment and materials in the box. c) Use the foot switch to fine-tune the tank pressure. 3.3. Foot pedal: can control the pressure of the glove box, easy operation. 4.Circulation system (including purification and regeneration system) (two sets) 4.1. Germany BASF, United States UOP purification material, Germany Baode valve. The host system is integrated with modular design, automatic electronic control gas solenoid valve group, PLC control, circuit, circulating pump, purification, display integrated with an independent purifier, forming a compact and simple system. 4.2. Control: Water and oxygen are controlled at less than 1ppm. 4.3 Adjustment device: through the PLC touch type adjustment (heating, evacuation, purification, regeneration) the whole process except 2.5 hours of ventilation without human monitoring. 4.4. Working gas: He.N2/ or Ar gas (gas cycle) 4.5. Circulating fan: 0-100m³ high speed variable frequency fan, microprocessor controlled, pressure tested stainless steel device. 4.6. Purification column: single purification column, imported purification material Germany BASF deoxygenation material 5kg, the United States UOP efficient water absorption material 5kg, extremely high life, to ensure that the user in the use of the product purification capacity long-term lasting. Water removal capacity 2.2㎏ oxygen absorption capacity 63L. 4.7. Purification valve: automatic electro-pneumatic valve. 4.8. Filter: High efficiency filter with HEPA standard 0.3 micron aperture filter. 4.9, regeneration: used for purification system reuse, so that it is activated; Regeneration requires a mixture of helium /H2, nitrogen /H2, or argon /H2, with H2 accounting for 10%. The recycled gas first flows into the flowmeter and then into the purification column. 5. Display system (two sets) Germany SIEMENS, unit control using Siemens PLC touch screen. Both Chinese and English can be switched. 6.Water analyzer, (imported from abroad) Brand material: UK MICHELL/ ((two sets)) Non-domestic or domestically assembled, third-party data guarantees credibility. 1) Measuring range: 0-1000ppm 2) Accuracy: ±1% ppm 3) Display: The output of the analyzer is connected to the PLC, the detection value is displayed on the touch screen, and the alarm value can be set. 4) Control: The gas circulation system can be controlled according to the user's setting to achieve cycle drop. 5) Environment: -10℃ -50 ℃ 7.Oxygen analyzer, (imported from abroad) Brand material: AVCRAY ((two sets)) Non-domestic or domestically assembled, third-party data guarantees credibility. 1) Measurement range can be set: 0-1000, ppm 2) Environment: -10℃ -50 ℃ 3) Accuracy: ±1% ppm 4) Installation position: The oxygen sensor is installed on the box, regardless of gas circulation or not, the oxygen sensor continuously detects the atmosphere in the box and shows the oxygen content in the glove box. 5) Sensor: electrochemical material battery, its advantages are zero accurate, small drift, to avoid other battery materials easy to be corroded; Low replacement cost (only oxygen battery replacement). 6) Display: The output of the analyzer is connected to the PLC, the detection value is displayed on the touch screen, and the alarm value can be set. Control: The user can choose the automatic cycling function to maintain the oxygen content in the glove box within the user's specified range. 8. Vacuum system (two sets) Added vacuum pump start-stop time control. Vacuum pump selected British Edwards vacuum pump, model RV12, flow 12m3/h, limit vacuum 2x10-3 mbar. The transition chamber can be vacuumed separately and can be controlled separately at any time. (imported from abroad) 9. Box automatic cleaning (two sets) Automatic gas control plating plate; The user sets the cleaning time, and then touch the start button on the touch screen, the system will start cleaning the box, and automatically stop at the set time. 10. Organic solvent adsorption system (two sets) In order to prevent the influence of organic solvents on the purification column, a solvent column is connected in series to the glove box system, and the medium is mainly high-quality and efficient activated carbon and activated alumina to prevent the formation of hydrofluoric acid. The organic solvent adsorption system is filled with 7KG, and there is a KF40 interface on the top and bottom of the column, which is convenient for refueling, and the user can refueling by himself. 11. Equipment working conditions: (provided by the user) 1.Power supply: two-phase three-wire AC220V, power 3Kw; 1.1 The laboratory should have an independent ground wire: < 3Ω, from the equipment to the ground wire connection is recommended to use ≥10mm2 flat copper wire; 1.2. Water supply: None; 1.3. Relative humidity: < 75%; 1.4. No large amount of dust, no corrosive, flammable and explosive gas in the room; 1.5. Equipment floor area: length × width :3700mm× 1200mm C. The main configuration No Disposition Unit Qty Manufacturer/Brand Remark 1 Box Pcs 2 Tmaxcn 304 stainless steel thickness 3mm 2 Transition compartment Set 3 Tmaxcn 304 stainless steel (including T-bin and 2 small bins) 3 Control system Set 2 Germany SIEMENS Omron electronic devices, etc Import assembly 4 Circulation system (including purification and regeneration system) Set 2 Germany BASF, United States UOP purification materials, Germany Baode valve Import assembly 5 Display system Set 2 SIEMENS Import 6 Gloves Pcs 6 America Import 7 Pipe joint Set 2 French Rocle Import 8 Manometer Set 3 WIka, Germany Import 9 PLC water analyzer Pcs 2 Michell Import 10 PLC oxygen analyzer Pcs 2 American AVCRAY Import 11 Vacuum pump Pcs 2 RV12 Import 12 Organic solvent adsorption Set 2 Tmaxcn 304 stainless steel D.Picture detail

-

304 Stainless Steel Vacuum Glove Box with Purification And Regeneration System

304 Stainless Steel Vacuum Glove Box with Purification And Regeneration System

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588