products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

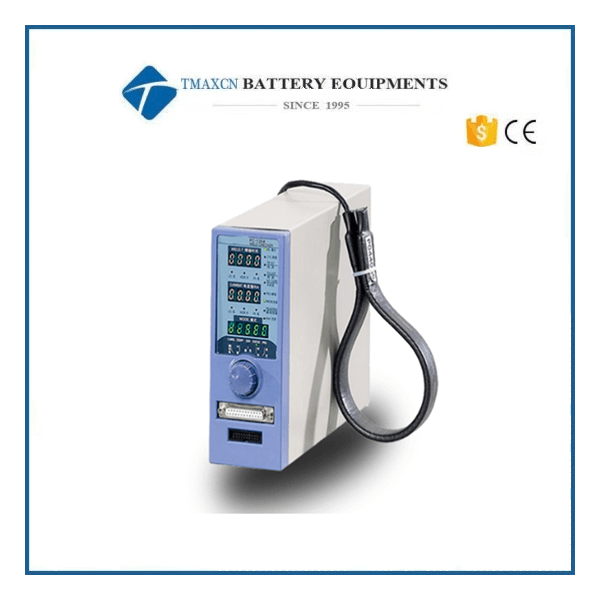

Welding Current Detector for Spot Welding Machine

Model Number:

TMAX-PC-120AInput Power:

800WDimension(L*W*H):

L246*W70*H190mmNet Weight:

2.5kgCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPlace of Origin:

ChinaUpdate:

OptionalShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Double Sides 8-Axis Electric Rotary Welding Head Spot Welding Machine for Solar Light Battery Pack/Power Battery /E-Vehicles Pack MakingNext:

Single Side 5000A/8000A Automatic Spot Welding Machine with Rotary Head with Host Computer Program for EV/ Electric Bike/Power Battery Making

Welding Current Detector for Spot Welding Machine

Feature

1. The welding current detector can measure the output current of AC welding power supply, intermediate frequency inverter welding power supply, energy storage welding power supply and transistor welding power supply, and real-time monitor and display the power on time of welding power supply

2. No need to choose the site of lightweight model, can be matched with any automatic welding equipment

3. Only one operation key is needed for "[rotate, press]" action, which is easy to operate

4. Ms or CYC and range can be freely selected for power on time measurement, and multiple test modes can be selected

5. It can be used for current monitoring of AC spot welding machine, intermediate frequency inverter spot welding machine, capacitor energy storage spot welding machine and secondary rectification welding machine. It can be used as current analyzer and tester

6. The monitoring data can be recorded and stored by expanding peripheral components, and the quality can be tracked.

We provide a full series of Energy Storage Battery Assembly for different customers.

Specification

Model |

TMAX-PC-120A |

Power |

P<800W |

Input Voltage |

AC 220V |

Weight |

2..5kg |

Current Testing Range |

(1) 0.01-0.200KA (when the coil with 10 times of impression is used) (2)0.01-1999KA (3)1.00-19.99KA (4)10-1999KA |

Size |

L246*W70*H190mm |

![]()

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588