products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

TMAX Brand Small Jaw Crusher For Laboratory Solid Sample Preparation

Model Number:

TMAX-JT-E200Input Power:

1.1KWNet Weight:

70KGCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technicalPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

2 Working Stations Laboratory Jar Ball Mill with Self-locking DeviceNext:

Mini Lab Vertical Semi-Circular Arc Planetary Ball Mill with Optional Material Tank

TMAX Brand Small Jaw Crusher For Laboratory Solid Sample Preparation

JT-E200 Small Jaw Crusher is a professional instrument for laboratory solid sample preparation. It has the characteristics of low noise, fast crushing speed, and fast sample size adjustment device. Rapid coarse crushing and pre-grinding treatment of brittle, hard, medium-hard, hard-ductile materials, such as ore, core, rock, slag, soil, ceramics, brittle material products, dried shells, dried sea cucumbers and other samples. The machine can adjust the crushing gap of the jaw plate through zero point correction to achieve the Z-optimized crushing effect.

Application

Geological minerals: rock, granite, basalt, silicate, etc.

Glass industry: glass, raw materials, etc.

Ceramic industry: sintered ceramics, electric ceramics, clay, etc.

Construction industry: slag, stone, cement, etc.

Environmental industry: soil, solid waste, etc.

Marine life: dried shells, dried sea cucumbers, etc.

Working principle

The prepared sample enters between the two jaws, and the jaws crush the sample. Under the action of gravity, the crushed sample falls into the collection box along the wedge-shaped cavity. The sample size depends on the adjusted two jaws. The gap between the plates, the adjustable jaw plate gap ensures the best crushing effect of the sample.

Technical Features

Zero point correction to compensate for wear and ensure the accuracy of sample fineness

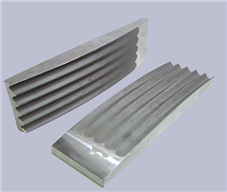

A variety of crushing jaws of different materials can be selected

Desktop design, saving experimental space

The instrument has an anti-splash design to ensure the safety of operators

The feeding hopper can be turned upside down, and the crushing cavity is easy to clean

Jaw plate can be reversible

Technical parameter

Feeding particle size: ≤45mm

Zero-Calibration: Yes

Discharge particle size: ≤0.5mm

Speed: adjustable from 100-1000rpm

Funnel: can be turned over

Sample size adjustment range: 0-12mm (adjustable)

Motor power: 1.1kw

Power: 220V 50Hz

Grinding kit material: high manganese steel, stainless steel, zirconia, tungsten carbide, industrial plastics

Net weight: 70kg

ru

ru

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588