products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Supercapacitor Electrode Materials Dry Electrode Film

Model Number:

TMAX-Electrode-7Dimension(L*W*H):

CustomizedCompliance:

CE CertifiedWarranty:

1 yearShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

15 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Customized Supercapacitor & Lithium Ion Battery Electrodes Anode And Cathode Electrode For High Energy Density Battery And SupercapacitorNext:

Battery Anode Substrate Lithium Battery Anode Current Collector Material

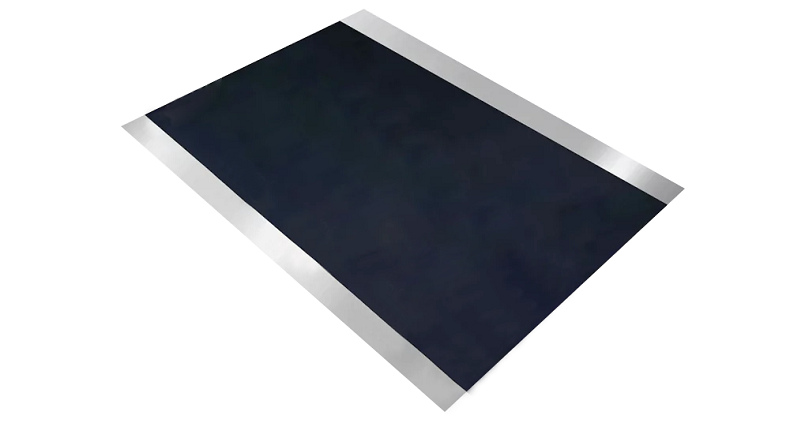

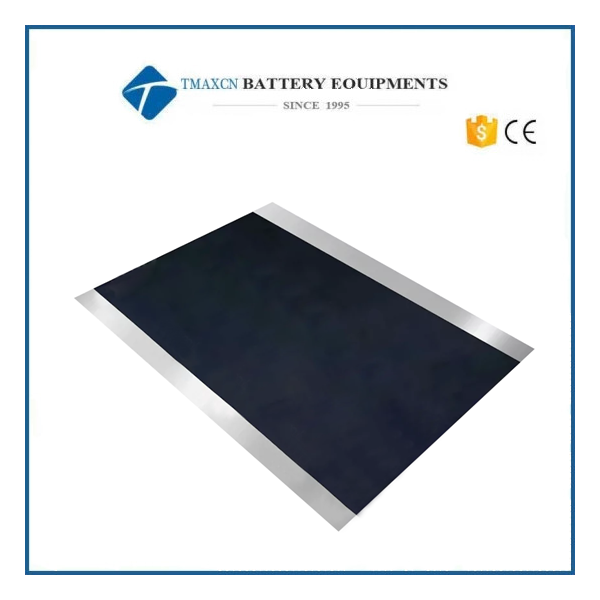

Supercapacitor Electrode Materials Dry Electrode Film

TMAX provides the dry electrode film for supercapacitors manufacturing and research.

MOQ: 400m/roll, 100m2/roll (Determine based on customization)

Main raw materials: activated carbon,aluminum foil (20C054)

Main parameter |

|

Item |

Parameter |

Appearance |

Appearance without abnormal incisions, scars, protrusions, and neat winding |

Thickness |

250±10 μm |

Compacted density |

≥0.66g/cm3 |

Moisture content |

≤3% |

Total width |

250±1mm |

Coated width |

220±2.0mm |

Foil thickness |

20±2um |

Outer diameter of electrode coil |

≤400mm |

Inner diameter of winding shaft |

75.5±1mm |

End face flatness |

±1mm |

Length of joint adhesive tape |

≤60mm |

Packaging and transportation

Packaging material: cardboard box.

Packaging method: Vacuum sealed packaging.

Pay attention to moisture-proof, waterproof, and light proof storage.

Transportation requirements: prevent collision, compression, moisture, sun protection, and damage.

Storage environment(electrode packaging in sealed state)

Temperature: -40 ℃~60 ℃

Relative humidity: 75% RH Max

The shelf life: 12 months.

Product Display:

Production Machine:

Package:

Detailed Images

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588