products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

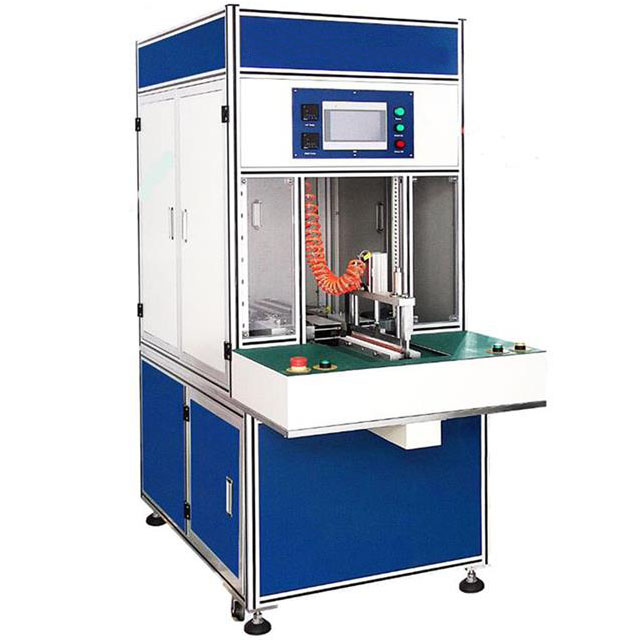

Semi-automatic Battery Edge Trimming Machine For Lithium Polymer Battery

Model Number:

TMAX-300HHDimension(L*W*H):

2000X 850 X 1800 mmNet Weight:

360KgCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Hot Press Pressure Pouch Cell Formation MachineNext:

600L vacuum planetary mixer for battery research

Semi-automatic Battery Edge Trimming Machine For Lithium Polymer Battery

TMAX300HH is a three-in-one machine provides the continuous workflow for edge trimming, folding and ironing of extra large pouch cell cases without dedicated labor. This process is widely used in the final steps of pouch cell battery pilot-scale production line to ensure a smooth, neat and tidy casing edge.

Ironing Module |

|

Trimming Module |

|

Folding Module |

|

Max. Power Consumption |

2.5KW |

Working Voltage |

208-240 VAC, single phase |

Compress Air Pressure |

· 0.7 - 0.8 MPa (Each stroke will consume 0.09L air ) · Note:Air Compressor is not included. |

Size Info (Edge Ironing, Trimming & Folding Width/Length) |

· Cell length: 10~370mm · Cell width: 10~150mm · Cell thickness: 2~12mm |

Temperature Info |

Ironing Temperature: 0-250℃ adjustable |

Dwell Time |

0-99 seconds adjustable |

Productivity |

160~220 pcs / hr (Expected lifespan of Trimming blade ~ 1 million times) |

Trimming accuracy |

+/-0.1mm |

Working Modes

|

· Continuous workflow for edge trimming, folding and ironing of extra large pouch cell cases (manual cases loading is needed) · Linear sliding rail for easy manipulation of trimming, folding and ironing modules.

|

How to use

|

When the pouch cell is fabricated, an uneven edging excess is expected. In order to make a neat and tidy cell with smooth edge just like the commercial pouch batteries, please follow the steps in below:

|

Product Dimensions |

2000X 850 X 1800 mm |

Net Weight |

360Kg |

Warranty |

Two Years limited warranty with lifetime support. |

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016 18659217588

18659217588